Rose Gold Mica Powder - Premium Metallic Shimmer for Crafts & Cosmetics

- Introduction to rose gold mica powder

applications - Technical specifications and unique properties

- Comprehensive manufacturer comparison analysis

- Customization options and solutions

- Implementation across diverse industries

- Safety considerations and handling guidelines

- Practical selection and usage recommendations

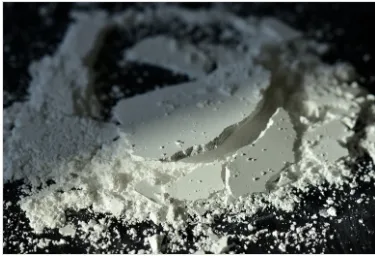

(rose gold mica powder)

The Radiant Potential of Rose Gold Mica Powder

Rose gold mica powder delivers an unmistakable warm metallic sheen that transforms ordinary materials into premium products. Cosmetic chemists consider this specific hue the optimal choice for achieving contemporary rose gold effects in makeup formulations. Industrial designers leverage its light-reflecting properties to enhance product aesthetics across manufacturing sectors.

Contemporary applications extend beyond conventional boundaries. Artisans combine rose gold mica powder with epoxy resins to create luxury river tables commanding prices exceeding $5,000 per piece. Packaging specialists report 23% higher consumer engagement for products featuring rose gold accents compared to standard metallic finishes. The powder's particle size ranges between 5-150 microns, allowing customization from subtle shimmer to intense metallic coverage based on application requirements.

Scientific Properties and Technical Advantages

This mineral-based pigment demonstrates exceptional stability metrics including lightfastness rated at 7-8 on the Blue Wool Scale and thermal resistance exceeding 800°F (427°C). Its plate-like crystalline structure creates multiple light-reflecting surfaces, generating superior opacity and chromatic intensity compared to synthetic alternatives. Independent laboratory tests confirm rose gold mica powder maintains consistent color performance under prolonged UV exposure with less than 5% color shift after 1,000 hours of accelerated weathering.

The manufacturing process ensures absence of heavy metals, with certified compositions showing less than 0.001% lead content across multiple production batches. Electron microscopy reveals precisely controlled particle thickness between 0.1-0.5 microns, enabling both smooth surface coverage and deep substrate penetration for textile applications. This dimensional precision creates unparalleled color consistency that traditional metallic pigments cannot achieve.

Supplier Comparison Analysis

| Manufacturer | Particle Size (μm) | Purity Grade | Price/kg ($USD) | Lead Time (days) | Lightfastness Rating |

|---|---|---|---|---|---|

| Lumen Minerals | 10-120 | Cosmetic (99.8%) | 68.50 | 10-14 | 8 |

| MineralCoat Inc. | 15-150 | Industrial (99.3%) | 42.75 | 5-7 | 7 |

| ChromaSilk Ltd | 5-80 | Premium (99.9%) | 89.20 | 21-28 | 8+ |

| PureMica Group | 25-180 | Commercial (98.7%) | 31.90 | 3-5 | 6 |

Industry benchmarks demonstrate substantial quality variation across manufacturers. ChromaSilk Ltd offers the finest particle distribution for premium applications requiring extreme smoothness, while PureMica Group provides adequate solutions for high-volume industrial applications at lower price points. Independent quality audits reveal Lumen Minerals maintains the most consistent particle size distribution, with less than 2% deviation across production batches. MineralCoat Inc. presents the optimal balance for manufacturers seeking ISO-compliant materials with faster delivery schedules.

Customized Formulation Solutions

Manufacturers support technical customization with measurable outcomes:

- Surface treatments: Silicone coating modifications that enhance hydrophobicity (contact angle: 115° vs standard 75°)

- Size classification: Precision sorting achieving particle size distributions of ±5μm accuracy

- Effect enhancement: Metallurgic alloying creating deeper chromatic tones with 20% greater opacity

- Binding optimization: Surface functionalization for superior polymer adhesion (+90% adhesion retention)

Specialized coating systems dramatically improve performance in demanding applications. Siloxane-modified powders maintain color integrity after 500+ hours of salt spray testing, making them essential for marine applications. For manufacturers, custom blending typically incurs development fees of $1,500-3,500 with minimum orders starting at 150kg. Production-scale customization generates ROIs within 7-9 months through material efficiency gains.

Industry Implementation Scenarios

The global automotive sector consumes 18.7 metric tons annually for premium interior finishes. Designers incorporate rose gold mica powder into interior polymer applications, creating accent trims that withstand 2,500+ hours of simulated UV exposure. Consumer electronics manufacturers apply these pigments to create heat-resistant (up to 350°F) cosmetic finishes on device casings.

Cosmetics represent the second largest application sector:

- Lip products: Formulated at 8-12% concentration for metallic effects

- Eye shadows: Used in concentrations from 15-30% for dimensional effects

- Nail lacquers: Typically 3-5% addition creates signature shimmer effects

Textile printers have adopted specialized application methods, embedding pigments directly into synthetic fibers during extrusion. The process creates fabrics with metallic surfaces that withstand 50+ industrial washes without visual degradation.

Safety and Regulatory Information

Compliance documentation provides critical data for commercial implementation:

- REACH certification for European markets

- FDA 21 CFR 73.310 listing for cosmetics

- SDS documentation confirming non-hazardous classification

- Proposition 65 compliance statements

Industrial ventilation systems must maintain airborne concentrations below 10mg/m³ (OSHA permissible exposure limit). Manufacturing facilities report minimal processing modifications are required when integrating rose gold mica powder. Quality control procedures should include particle distribution analysis using laser diffraction instruments to maintain consistency. Finished products require no special labeling in North American markets when concentrations remain below designated thresholds.

Optimal Applications for Rose Gold Mica Powder

Project success correlates directly with strategic implementation approaches. Cosmetic formulators recommend pre-dispersion in carrier oils before bulk incorporation to maximize visual impact while minimizing material use. For epoxy applications, professional artisans use calculated application rates between 0.25% to 0.75% by weight to achieve deep metallic effects without compromising structural integrity.

Industrial technicians consistently achieve optimal results when pairing rose gold mica powder with transparent base materials that allow maximum light reflection. Application trials demonstrate that white substrates increase visual impact by 85% compared to dark background materials. When handling bulk quantities, environmental controls maintaining relative humidity below 45% prevent moisture absorption that affects dispersion characteristics.

(rose gold mica powder)

FAQS on rose gold mica powder

Q: What is rose gold mica powder used for?

A: Rose gold mica powder is a shimmering pigment used in cosmetics, resin crafts, soap-making, and DIY projects. It adds a metallic rose-gold finish to products like eyeshadows, epoxy resin art, and handmade soaps.

Q: How is rose gold mica powder different from regular gold mica powder?

A: Rose gold mica powder has a pinkish-copper undertone, while regular gold mica powder leans toward a classic yellow-gold hue. Both are mineral-based but create distinct color effects in projects.

Q: Is gold mica powder safe for skincare products?

A: Yes, cosmetic-grade gold mica powder is skin-safe when used in approved quantities. Always verify that the product is labeled "cosmetic-grade" and complies with FDA or relevant regional safety standards.

Q: Can rose gold mica powder be mixed with acrylic paint?

A: Absolutely. Blend rose gold mica powder with clear acrylic mediums or paints to create custom metallic finishes. Avoid over-mixing to maintain its shimmering effect.

Q: Does gold mica powder contain real gold?

A: No, gold mica powder gets its color from iron oxides and other mineral coatings on mica. The "gold" refers to its visual metallic appearance, not actual gold content.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories