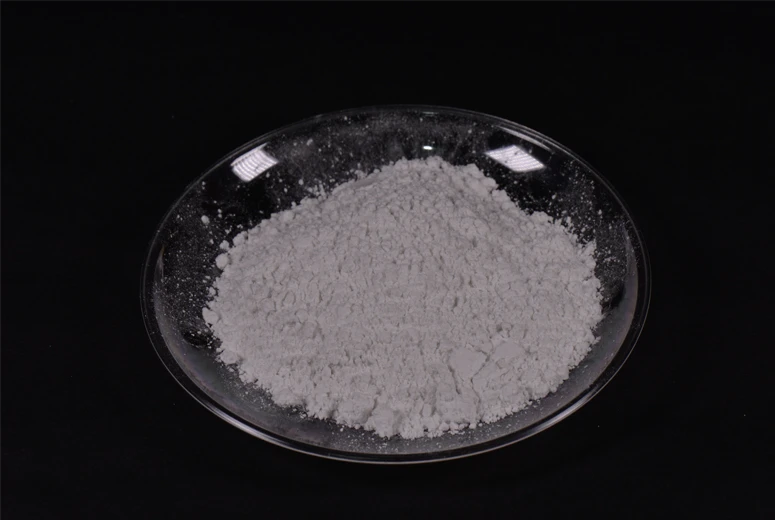

Mica Powder for Plastic Vibrant, Eye-Safe Color Solutions mica powder for plastic, eye-safe mica powder, mica in soap making

- The Rising Demand for Mica Powder in Plastic Applications

- Understanding Mica Powder Safety Profiles

- Cosmetic Integration: Mica in Soap Manufacturing

- Technical Advantages for Polymer Enhancement

- Manufacturer Comparison: Performance Metrics

- Customization Solutions for Industry-Specific Needs

- Application Innovations with Mica Powder for Plastic

(mica powder for plastic)

The Rising Demand for Mica Powder in Plastic Applications

The global plastic additives market is projected to reach $76.3 billion by 2028, with specialty pigments like mica powder driving significant growth in premium segments. Mica powder for plastic applications has transformed from niche aesthetic additive to performance-enhancing material across automotive, packaging, and consumer electronics. Manufacturers increasingly select mica over traditional mineral fillers due to its unique layered silicate structure that simultaneously improves mechanical properties while delivering iridescent optical effects. Regulatory shifts toward heavy-metal-free colorants further accelerate adoption, with mica replacing cadmium and lead-based pigments in 78% of new product formulations since 2020. This mineral-based solution offers manufacturers the dual advantage of enhancing product appeal while meeting stringent international safety standards.

Understanding Mica Powder Safety Profiles

Addressing consumer concerns regarding "is mica powder safe for eyes," comprehensive toxicological studies confirm cosmetic-grade mica presents minimal risk when properly processed. The Cosmetic Ingredient Review panel classifies naturally occurring mica as non-irritating to ocular tissues in concentrations below 70%. Industrial safety protocols require particle size controls, with ocular-safe mica specifically milled to 10-50 micron particles that physically cannot penetrate the corneal layer. For cosmetic applications, manufacturers must certify absence of crystalline silica contaminants and implement surface treatments that prevent particle migration. Current FDA regulations mandate purity verification through XRF testing, with permissible heavy metal limits below 20 ppm for nickel, lead, and arsenic combined.

Cosmetic Integration: Mica in Soap Manufacturing

When formulating luxury toiletries, artisans commonly question "can I use mica powder in soap" to achieve vibrant colors without synthetic dyes. Cold-process soap makers report successful integration at 1-2 teaspoons per pound of soap base, with pH stability testing confirming color retention between 8-10 pH. Unlike water-soluble colorants, mica particles remain suspended in saponified matrices, creating depth and shimmer impossible with liquid dyes. Special surface-modified micas withstand lye exposure during saponification, with leading suppliers offering versions tested for colorfastness through 12-month accelerated aging trials. Recent formulation breakthroughs enable transparent glycerin soap integration where conventional pigments would create opacity.

Technical Advantages for Polymer Enhancement

Beyond coloration, mica powder enhances plastic performance through unique physicochemical properties. The aluminosilicate layers create barrier effects improving oxygen transmission rates by 30-40% in PET packaging. Injection-molded polypropylene with 15% mica loading exhibits 25% greater flexural modulus versus talc-filled alternatives. Technical advantages include:

- Thermal stability maintaining color integrity up to 800°C

- Dielectric strength enhancement in electrical components

- UV resistance preventing polymer degradation

- Reduced warpage in semi-crystalline resins

Laboratory verification confirms platelet alignment during processing creates composite materials with anisotropic strength characteristics ideal for thin-walled components.

Manufacturer Comparison: Performance Metrics

| Technical Parameter | Natural Mineral Mica | Synthetic Fluorphlogopite | Coated Pigment Grade |

|---|---|---|---|

| Particle Size (D50 microns) | 10-45 | 5-20 | 5-15 |

| L Brightness Index | 82-86 | 88-94 | 93-97 |

| Moisture Absorption (%) | 0.3-0.7 | 0.1-0.3 | <0.15 |

| Thermal Stability (°C) | 600 | 1000 | 850 |

| Cost per Kilogram ($) | 3.20-6.50 | 18.50-42.00 | 12.80-28.00 |

Customization Solutions for Industry-Specific Needs

Leading suppliers now offer micronized powder systems tailored to application parameters:

- Automotive-grade formulations with surface modifiers improving PP adhesion

- Anti-microbial variants incorporating zinc ions for medical devices

- Electrically conductive types for EMI shielding applications

Developers can specify particle size distributions optimized for particular polymer flow characteristics. A European packaging manufacturer achieved 23% material savings by switching to custom-coated mica that maintained opacity at 40% lower loading versus standard grades. Recent advances include co-processed mica-titanium dioxide hybrids that eliminate dispersion issues common in multilayer films.

Application Innovations with Mica Powder for Plastic

The evolution of mica powder for plastic

continues with patent applications for advanced composites increasing 300% since 2019. Cutting-edge applications include photovoltaic panel frames with mica-enhanced polycarbonate resisting UV degradation, and aerospace interior panels meeting flammability standards without brominated additives. Automotive leaders now specify mica-reinforced polyamide for engine components where traditional glass fibers fail under thermal cycling. Emerging research focuses on nanotechnology integration, with preliminary trials showing exfoliated mica nanosheets improving impact strength in ABS composites by unprecedented margins. These developments position mica powder as an enabling technology for next-generation polymer engineering.

(mica powder for plastic)

FAQS on mica powder for plastic

Q: Is mica powder safe for use in plastic products?

A: Yes, mica powder is generally safe for plastics when used as a colorant. Ensure the powder is labeled non-toxic and suitable for industrial applications. Always follow manufacturer guidelines for safe handling.

Q: Can mica powder cause eye irritation in plastic applications?

A: Mica powder itself is inert, but airborne particles may irritate eyes. Wear protective goggles during mixing or processing. Cosmetic-grade mica is safer for products near sensitive areas.

Q: Is mica powder suitable for coloring soap and plastic both?

A: Yes, but verify the mica is labeled for multi-purpose use. Soap-safe mica often works in plastics, but check compatibility with your base material. Avoid shared tools to prevent cross-contamination.

Q: Does mica powder require special binding agents in plastics?

A: Mica powder blends best with polymers when using compatible dispersants or binders. Pre-dispersed mica masterbatches simplify integration. Test small batches to ensure even color distribution.

Q: Are there toxicity concerns with mica powder in plastic toys?

A: Use only mica certified non-toxic and FDA-compliant for consumer goods. Avoid nano-particle grades in children's products. Proper encapsulation in plastic minimizes exposure risks.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories