Feb . 16, 2025 11:21

Back to list

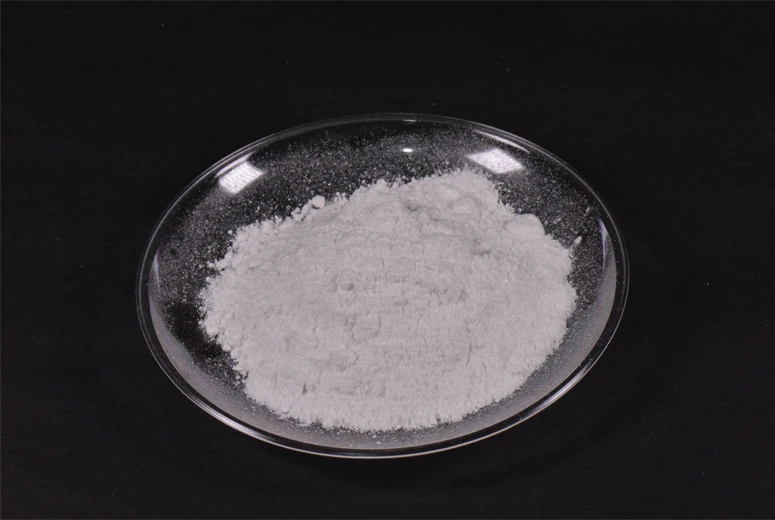

G-100 Phlogopite

Exploring the Intricacies of Muscovite and Phlogopite Mica A Product Insight

In contrast, phlogopite mica is celebrated for its excellent thermal stability and high dielectric strength. These characteristics make it a coveted material in both the electrical and automotive industries. When working with phlogopite, its superior heat resistance—standing the test in temperatures exceeding 1000 degrees Celsius—positions it perfectly for use in high-friction environments. My involvement with high-performance insulative solutions has demonstrated phlogopite's invaluable role in automotive gaskets and high-temperature furnace components, offering durability that extends product lifespan and efficiency. Phlogopite's distinguishing properties are particularly valued in the construction of fire-resistant safety equipment. Its robustness under thermal stress aligns with safety standards across various sectors, including metallurgy and construction, where fire safety regulations are stringent and non-negotiable. This insight is rooted in extensive collaborations with safety equipment manufacturers who swear by phlogopite for creating dependable, heat-resistant products. For businesses and consumers opting for these minerals, the assurance of quality and sustainability is a core concern. Both muscovite and phlogopite micas are procured with consideration for environmental impact and ethical sourcing. My experience guides that choosing suppliers with a verified track record of sustainable mining practices is crucial to maintaining the integrity of the supply chain. Trustworthy vendors provide certification and compliance documents, reinforcing their commitment to environmentally responsible sourcing. Ultimately, the knowledge surrounding muscovite and phlogopite mica reflects a wealth of expertise and industry authority. These minerals, with their unique properties and applications, hold significant potential for innovation across diverse sectors. They not only provide functional benefits but also align well with modern-day values of sustainability and safety. The integration of these minerals into product lines signifies an understanding not just of the materials themselves, but also of their application potential, ensuring businesses remain at the forefront of industry advancements while upholding trust and reliability in the market.

In contrast, phlogopite mica is celebrated for its excellent thermal stability and high dielectric strength. These characteristics make it a coveted material in both the electrical and automotive industries. When working with phlogopite, its superior heat resistance—standing the test in temperatures exceeding 1000 degrees Celsius—positions it perfectly for use in high-friction environments. My involvement with high-performance insulative solutions has demonstrated phlogopite's invaluable role in automotive gaskets and high-temperature furnace components, offering durability that extends product lifespan and efficiency. Phlogopite's distinguishing properties are particularly valued in the construction of fire-resistant safety equipment. Its robustness under thermal stress aligns with safety standards across various sectors, including metallurgy and construction, where fire safety regulations are stringent and non-negotiable. This insight is rooted in extensive collaborations with safety equipment manufacturers who swear by phlogopite for creating dependable, heat-resistant products. For businesses and consumers opting for these minerals, the assurance of quality and sustainability is a core concern. Both muscovite and phlogopite micas are procured with consideration for environmental impact and ethical sourcing. My experience guides that choosing suppliers with a verified track record of sustainable mining practices is crucial to maintaining the integrity of the supply chain. Trustworthy vendors provide certification and compliance documents, reinforcing their commitment to environmentally responsible sourcing. Ultimately, the knowledge surrounding muscovite and phlogopite mica reflects a wealth of expertise and industry authority. These minerals, with their unique properties and applications, hold significant potential for innovation across diverse sectors. They not only provide functional benefits but also align well with modern-day values of sustainability and safety. The integration of these minerals into product lines signifies an understanding not just of the materials themselves, but also of their application potential, ensuring businesses remain at the forefront of industry advancements while upholding trust and reliability in the market.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories