Feb . 16, 2025 11:03

Back to list

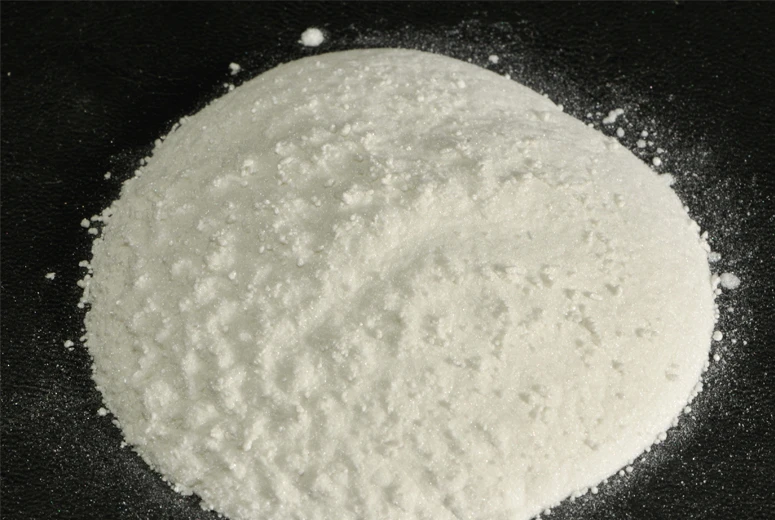

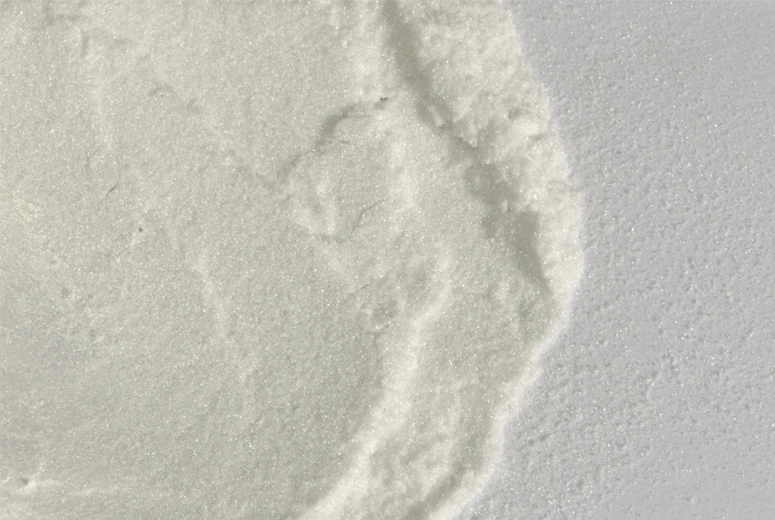

G-100 Phlogopite

Muscovite and phlogopite mica are two significant minerals in industrial applications, crucial for their unique properties that cater to various sectors. Muscovite mica, characterized by its excellent electrical insulating properties and resistance to heat, is widely utilized in the electronics and electrical industries. Its natural sheen and ability to be split into thin sheets make it a preferred choice for creating insulators in capacitors and other electronic components where precision and reliability are paramount.

Authoritativeness in the supply and demand of muscovite and phlogopite is supported by comprehensive geological surveys and rigorous quality assessments, ensuring that the materials sourced are of optimal standard and purity. Certified suppliers are checked routinely to maintain quality benchmarks, reinforcing trust and credibility in industrial applications. Critical to the manufacturing processes of these minerals is adherence to environmental regulations and sustainable sourcing practices, ensuring reduced carbon footprints and ethical mining approaches. These measures support long-term growability and sustainability in the industries that depend on these minerals. Trustworthiness in the application of muscovite and phlogopite mica arises from their well-established benefits and the extensive scientific research backing their uses. Clients in high-stakes industries, such as aerospace and electronics, rely on the dependable performance of these micas to innovate and excel. Companies providing these minerals ensure transparency in their supply chain and offer guarantees on the technical specifications of their products. This transparency is vital for businesses that depend on the timely and efficient delivery of these materials. The future advancements in the applications of muscovite and phlogopite mica are promising, with ongoing research into their potential uses in nanotechnology and renewable energy solutions. Researchers are actively exploring how the exceptional properties of these minerals can augment solar panels’ efficiency or contribute to more durable and eco-friendly construction materials. Their natural ability to withstand harsh environments and provide superior insulation opens new possibilities in engineering and technology, driving further inquiries and experimentation. In conclusion, muscovite and phlogopite mica remain at the forefront of critical industrial applications due to their unique characteristics and the continuous innovation surrounding their uses. Their roles in enhancing product performance and sustainability are a testament to their lasting impact across various sectors. As technology evolves, the potential of these minerals to contribute to groundbreaking advances can only be expected to grow, further cementing their place as indispensable materials in both current and future industries.

Authoritativeness in the supply and demand of muscovite and phlogopite is supported by comprehensive geological surveys and rigorous quality assessments, ensuring that the materials sourced are of optimal standard and purity. Certified suppliers are checked routinely to maintain quality benchmarks, reinforcing trust and credibility in industrial applications. Critical to the manufacturing processes of these minerals is adherence to environmental regulations and sustainable sourcing practices, ensuring reduced carbon footprints and ethical mining approaches. These measures support long-term growability and sustainability in the industries that depend on these minerals. Trustworthiness in the application of muscovite and phlogopite mica arises from their well-established benefits and the extensive scientific research backing their uses. Clients in high-stakes industries, such as aerospace and electronics, rely on the dependable performance of these micas to innovate and excel. Companies providing these minerals ensure transparency in their supply chain and offer guarantees on the technical specifications of their products. This transparency is vital for businesses that depend on the timely and efficient delivery of these materials. The future advancements in the applications of muscovite and phlogopite mica are promising, with ongoing research into their potential uses in nanotechnology and renewable energy solutions. Researchers are actively exploring how the exceptional properties of these minerals can augment solar panels’ efficiency or contribute to more durable and eco-friendly construction materials. Their natural ability to withstand harsh environments and provide superior insulation opens new possibilities in engineering and technology, driving further inquiries and experimentation. In conclusion, muscovite and phlogopite mica remain at the forefront of critical industrial applications due to their unique characteristics and the continuous innovation surrounding their uses. Their roles in enhancing product performance and sustainability are a testament to their lasting impact across various sectors. As technology evolves, the potential of these minerals to contribute to groundbreaking advances can only be expected to grow, further cementing their place as indispensable materials in both current and future industries.

Prev:

Next:

Latest news

-

Thermal Conductivity of Bulk Mica PowderNewsAug.08,2025

-

Storage Conditions to Maintain Blue Mica Flakes QualityNewsAug.08,2025

-

Storage Conditions to Maintain Mica Powder for Resin QualityNewsAug.08,2025

-

Shimmering Effects: Synthetic Mica Glitter vs Other GlittersNewsAug.08,2025

-

Safety Standards for Working with Mica DustNewsAug.08,2025

-

Color-Fastness of Mica Pigment PowderNewsAug.08,2025

Products categories