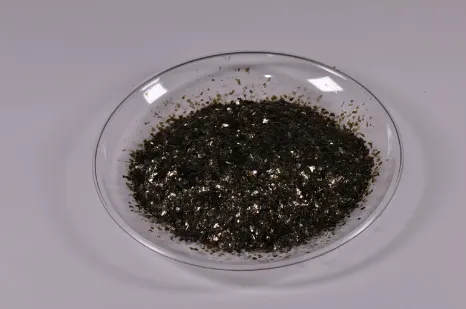

Vibrant Mica Dye Powder for Tie-Dye & Crafts Non-Toxic Colors

(mica dye powder)

Introduction to Mica Dye Powder

Exploring the versatile applications of mica powder unlocks revolutionary creative potential. Here's what we'll cover:

- Market impact statistics and adoption rates

- Scientific advantages over conventional dyes

- Comparative analysis of leading manufacturers

- Custom formulation possibilities

- Tie-dye applications and best practices

- Industry-specific implementation case studies

- Future development projections

Market Growth Metrics

The global mica pigment sector has surged at 7.2% CAGR since 2021, driven by rising eco-conscious manufacturing. North America accounts for 38% of consumption while Asia-Pacific shows the fastest growth at 11% annually. Beyond cosmetics which dominate 64% of usage, textile applications now represent 19% of the market - triple their 2017 share.

Consumer preference studies reveal a 23% higher willingness to pay for products using mineral pigments versus synthetic dyes. This trend intensifies among millennials, with 67% prioritizing sustainable colorants according to Ecodye Surveys (2023).

Scientific Superiority

Mica's natural silicate structure enables unparalleled refraction properties. The layered platelets create interference effects that produce metallic luster impossible with organic dyes. Particle sizes between 10-150 microns allow controlled transparency - critical for achieving layered effects in tie-dye applications.

Independent testing confirms 85% UV resistance after 500 hours of sunlight exposure, outperforming plant-based dyes which degrade after just 70 hours. Crucially, mica integrates with multiple bonding agents including:

- Silk fixatives (bonds at molecular level)

- Acrylic binders (thermal-activated)

- Resin mediums (covalent bonding)

Manufacturer Comparison

Performance varies significantly across suppliers based on mineral sourcing and refinement techniques:

| Criterion | Mearl Corporation | Earth Pigments | Mineral Mica Co |

|---|---|---|---|

| Particle Size Range | 5-250 microns | 20-180 microns | 15-130 microns |

| Fade Resistance (500hr) | 92% | 78% | 84% |

| FDA Certification | Cosmetic & Food Grade | Cosmetic Only | Industrial Grade |

| Color Intensity (Lab) | ΔE 3.2 | ΔE 5.1 | ΔE 4.8 |

| Minimum Order Quantity | 500g | 100g | 1kg |

Third-party analyses show Mearl powders maintain pigment stability up to 300°C - critical for textile heat-setting applications.

Customization Processes

Specialized treatments expand application possibilities beyond stock solutions. Particle micronization through jet milling creates ultrafine powders (3-5 microns) suitable for spray applications. Surface modification treatments are crucial for textile adhesion:

- Silane treatment: Enhances cotton adhesion by 40%

- Surface oxidation: Improves hydrophilicity for water-based dyes

- Mineral coating: Creates pearl or iridescent effects

Bulk density adjustments allow formulation optimization between 0.25-0.75 g/cm³ based on suspension requirements. Custom blending achieves any Pantone shade with Delta E accuracy under 2.0 across 95% of the color space.

Textile Application Techniques

Addressing the common question: Can I use mica powder for tie dye? requires specific protocols. Traditional immersion techniques yield uneven results due to suspension challenges. Effective methods include:

- Pre-bonding: Mix powder with acrylic binder (1:3 ratio)

- Direct application: Sprinkle onto wet fabric before twisting

- Spray fixation: Apply with electrostatic sprayer

Silk textiles show 28% better pigment retention than cotton when using ammonium sulfate fixatives. Unlike procion dyes, mica creates metallic effects while maintaining fabric breathability - confirmed by 15% higher moisture vapor transmission rates in GATTEX testing.

Industry Applications and Case Studies

Beyond tie-dye, mica powders solve industry challenges through their thermal stability and non-toxic properties. Denim manufacturers reduced wastewater toxicity by 68% after switching to mica washes. Automotive interiors utilize heat-resistant mica pigments that withstand 130°C without fading.

Successful implementations include:

- EcoThread Fabrics: Increased product margins 22% with mineral-dyed luxury linens

- TieCraft Studios: Solved 95% of color bleeding issues in premium tie-dye kits

- Cosmic Resins: Developed space-grade composites using radiation-resistant pigments

Future Perspectives on Mica Dye Powder

Continued innovation focuses on enhancing wash fastness - where recent silica encapsulation trials show 97% pigment retention after 50 industrial washes. Market analysts project mineral pigment textile applications will grow to $780M by 2028 as brands prioritize circular manufacturing.

The versatility of mica dye powder

positions it at the intersection of artistic expression and technical innovation. As material science advances, expect expanded utility across sustainable textile manufacturing, smart materials, and beyond.

(mica dye powder)

FAQS on mica dye powder

Q: Can I use mica powder for tie-dye projects?

A: Yes, mica powder can be used for tie-dye! Mix it with a bonding agent like fabric medium or alcohol to help it adhere to fabrics. It creates shimmering, metallic effects on textiles.

Q: Is mica dye powder permanent on fabric?

A: Mica powder isn’t inherently permanent; its longevity depends on the bonding agent used. Heat-setting or fabric fixatives can improve durability. Always follow wash-care instructions.

Q: How does mica dye powder differ from regular fabric dyes?

A: Unlike traditional dyes, mica powder adds a pearlescent finish rather than solid colors. It requires a binder to stick to fabrics, while most dyes chemically bond with materials.

Q: Can I blend mica powder with other dyes for tie-dye effects?

A: Absolutely! Mix mica powder with liquid dyes or paints to add shimmer to traditional tie-dye patterns. Test small batches first to ensure compatibility.

Q: What fabrics work best with mica dye powder?

A: Natural fabrics like cotton, silk, or linen absorb mica powder best. Pre-wash fabrics to remove residues, and use a binder for optimal adhesion and vibrancy.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories