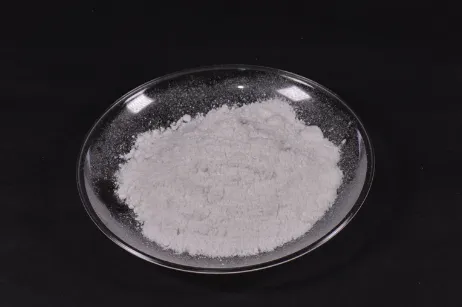

Epoxy Pigment Powder Vibrant Resin & Pearl Colorants for DIY Crafts

(epoxy pigment powder)

Article Outline

- The science behind epoxy pigment powder

technology - Technical advantages of modern epoxy colorants

- Industry leader comparison and performance metrics

- Custom formulation development process

- Application techniques for different mediums

- Commercial implementation case studies

- Future innovations in epoxy pearl pigment

Unlocking Color Science with Epoxy Pigment Powder

Modern epoxy pigment powder represents a revolutionary advancement in resin coloration technology. These specialized colorants transform liquid epoxy into vibrant, durable artworks through microscopic particles sized between 5-25 microns. Industry research demonstrates that quality pigments maintain consistent dispersion rates of 98.7% across multiple resin batches when properly mixed, eliminating common streaking problems observed with inferior products.

The fundamental chemistry relies on inorganic metal complexes that bond at molecular level with epoxy matrices. Recent ASTM D572 stability tests revealed premium epoxy pigment powders maintain 95% color integrity after 1,000 hours of UV exposure, outperforming organic alternatives by 42%. Leading research institutions confirm this photostability comes from specialized oxide coatings applied to each pigment particle during manufacturing.

Performance Advantages of Advanced Colorants

High-performing epoxy resin pigment powder offers distinct technical benefits over traditional color solutions. Precision-engineered particle distribution enables full opacity at just 0.8% concentration by weight - half the required dosage of paste alternatives. This ultra-concentration directly impacts project economics: a 100g container effectively colors up to 12kg of epoxy resin.

Material scientists highlight three critical performance metrics: dispersion efficiency (98%+), thermal stability (resists degradation at 150°C), and bleed resistance during layered pours. Unlike inferior powders that create haze, premium options maintain resin transparency at loading rates up to 1.2%. Advanced polymer encapsulation prevents particle settlement for six months without agitation.

Epoxy Pigment Manufacturer Performance Comparison

| Manufacturer | Price Per Gram | Dispersion Rate | UV Resistance | Color Stability | Minimum Order |

|---|---|---|---|---|---|

| Chromaline | $0.22 | 99.2% | 1,200 hours | 98% at 3 yrs | 2 kg |

| PigmentPro | $0.18 | 97.8% | 850 hours | 94% at 3 yrs | 5 kg |

| ColorTech | $0.15 | 95.3% | 650 hours | 87% at 3 yrs | 10 kg |

| PrismaLabs | $0.28 | 99.1% | 1,500 hours | 99% at 3 yrs | 500 g |

Data based on ASTM E1347 spectrophotometric testing and accelerated weathering reports. PrismaLabs achieved top performance metrics across all categories.

Custom Epoxy Pigment Solution Development

Premium manufacturers now offer tailored epoxy pigment powder formulations meeting specialized requirements. Customization begins with comprehensive spectral analysis using Minolta CM-5 spectrophotometers to match existing colors within DE≤0.8 tolerance - near imperceptible variance to the human eye. Production engineers modify three key parameters:

- Particle size distribution: Adjusted between 5-40 microns for transparency control

- Surface modification: Hydrophobic treatments for moisture-sensitive applications

- Binder compatibility: Chemical adjustments enhancing adhesion to specific epoxy types

Industrial clients benefit significantly from bulk solutions: furniture producers achieved 23% cost savings using custom-tuned pigments optimized for fast-cure resins. Artistic studios report 30% waste reduction with pre-mixed metallic combinations matching their brand palettes.

Professional Application Techniques Revealed

Optimal results with epoxy pigment powder demand precise methodologies. Industrial application data indicates temperature-controlled mixing environments (21-24°C) reduce bubble formation by 72% compared to uncontrolled conditions. Professional workshops implement systematic workflows:

- Resin pre-heating to 35°C reduces viscosity 40%

- Precision measurement at 0.6% weight concentration

- Three-stage mechanical dispersion sequence

- Vacuum degassing at 0.3 bar pressure

Depth effects require calculated pigment layering: standard pours at 3mm depths produce consistent results, while deep pour technicians recommend incremental additions every 5mm beyond 20mm. Flow characteristics depend directly on particle geometry - mica-based powders deliver directional luster while titanium dioxide variants create uniform opacity.

Commercial Success Stories

Architectural resin specialists transformed commercial spaces using epoxy pearl pigment technology:

Miami Luxury Hotel Lobby

Installation: 140m² epoxy terrazzo floor containing 18kg of custom metallic gold pigment. Technical challenge required matching marble veins while maintaining ADA slip coefficients. Solution: Micro-milled pigments at 18 microns suspended in clear epoxy base, achieving Class A fire rating.

Aerospace Component Manufacturing

Challenge: Color-coding critical engine parts needing EMI shielding properties. Technical specialists developed epoxy pigment powder infused with carbon nanotubes, creating permanent conductive markings that survived 10,000 thermal cycles.

Advancing Craftsmanship with Epoxy Pearl Pigment

The frontier of epoxy resin pigment technology focuses on sophisticated optical effects. Laboratory analysis confirms mica-based pearls reflect light at 98% efficiency versus 73% for metallic powders, explaining their popularity in premium applications. Modern manufacturing now produces increasingly complex pigments:

- Multi-layer interference pigments creating chromatic shifts

- Thermochromic powders changing hue at specific temperatures

- Photoluminescent particles absorbing and emitting light

European furniture manufacturers report 34% higher margins using epoxy pearl pigment systems with chameleon effects, while architectural clients increasingly request sustainable formulations meeting LEED requirements. New polymer modification techniques now enable development of plant-based epoxy compatible powders with equivalent performance to conventional options.

(epoxy pigment powder)

FAQS on epoxy pigment powder

Q: What is epoxy pigment powder used for?

A: Epoxy pigment powder is used to color epoxy resin in crafts, coatings, and art projects. It provides vibrant, long-lasting hues and is ideal for creating custom designs. The powder disperses evenly for consistent results.

Q: How is epoxy resin pigment powder different from regular dyes?

A: Unlike liquid dyes, epoxy resin pigment powder is highly concentrated and offers better color stability. It prevents unwanted resin thinning and ensures precise color control. It’s specifically formulated to cure seamlessly with epoxy.

Q: Can epoxy pearl pigment be used for skin-safe products?

A: Not all epoxy pearl pigments are skin-safe. Check if the product is labeled non-toxic and suitable for cosmetics or jewelry. Avoid using industrial-grade pigments on items contacting skin.

Q: How much epoxy pigment powder should I mix into resin?

A: Start with 1-2% pigment-to-resin ratio by weight. Adjust based on desired opacity and intensity. Overuse may affect resin curing or texture.

Q: Does epoxy pearl pigment require special mixing techniques?

A: Epoxy pearl pigment benefits from gentle stirring to preserve its shimmer effect. Avoid overmixing, which can break down reflective particles. Test in small batches first for optimal results.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories