High-Quality Synthetic Mica Cosmetics for Safe, Vibrant Makeup

- Explore the evolution of synthetic mica cosmetics: Market growth, technical breakthroughs, and new application fields

- Comprehensive comparison of HC40 Synthetic Mica vs. traditional natural mica solutions

- Detailed manufacturing process flow: From raw materials to pigment integration

- Parameter data, industry certifications (ISO, FDA), case studies, and manufacturer evaluation for informed sourcing decisions

1. Industry Trend Analysis: Synthetic Mica Cosmetics Market

The global synthetic mica cosmetics sector has witnessed exponential growth in recent years. According to Grand View Research (2023), the worldwide synthetic mica pigments market surpassed $560 million in 2022, with an expected CAGR of 7.9% from 2023 to 2030.

Major cosmetic brands (L'Oréal, Estée Lauder, Fenty Beauty) are increasingly adopting synthetic mica for sustainable, ethical, and performance reasons, replacing natural mica to meet regulatory and consumer demands for safety, traceability, and high purity.

2. Synthetic Mica Pigments: Technical Parameters Overview

| Parameter | Synthetic Mica | Natural Mica | Performance Benefit |

|---|---|---|---|

| Purity | ≥ 99.6% | 80~92% | Reduced heavy metals |

| Particle Size (μm) | 5–150 | 10–200 | Superfine gradation |

| Luster | High, pearl effect | Medium/variable | Superior brilliance, consistent sparkle |

| Traceability | Full (batch-level) | Low | Regulatory compliance (REACH/ISO) |

| Color Stability | Excellent | Susceptible to fading | Longer-lasting makeup |

| Certifications | ISO 9001, FDA, REACH | Variable | Safety assurance |

| Ethics/Trace | Child-labor free | Uncertain | Sustainable sourcing |

Synthetic mica pigments have outperformed natural mica in consistency, purity, and regulatory compliance—making them ideal for premium synthetic mica cosmetics formulations.

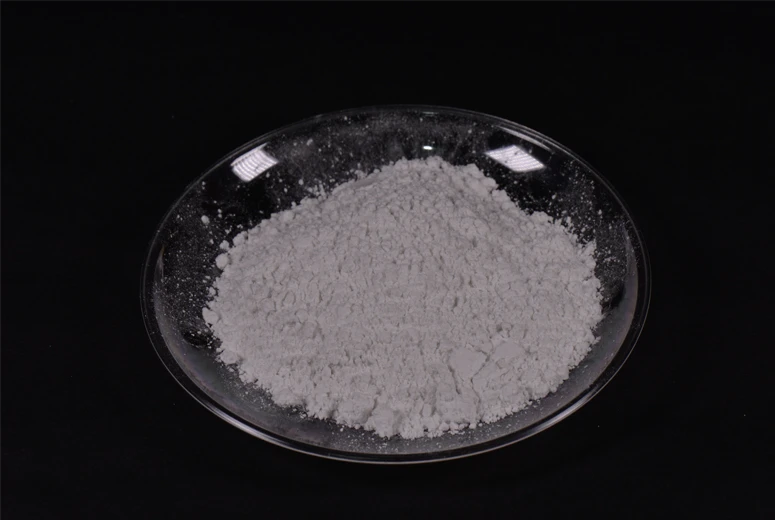

3. HC40 Synthetic Mica: Product Introduction & Core Advantages

Product Name:

HC40 Synthetic Mica- ISO 9001/FDA/REACH-certified

- Crystal-pure phlogopite composition

- Particle size range: 10–120 μm (customizable)

- Advanced heat, UV, & chemical resistance

- Optimized for makeup, coatings, plastics, and industrial applications

4. HC40 Synthetic Mica – Technical Specification Table

| Property | HC40 Synthetic Mica | Reference Spec |

|---|---|---|

| Chemical Formula | KMg3(AlSi3O10)(F,OH)2 | Phlogopite (Synthetic) |

| Purity (%) | >99.6 | ISO 9001/REACH |

| Particle Size (μm) | 10–120 (custom) | Customizable |

| Luster | Pearlescent, high gloss | - |

| Color | Transparent, silver/white | - |

| Heat Resistance | ≥ 1050°C | EN 14037 |

| pH Value | 6.5–8.5 | - |

| Heavy Metal Content (Pb/Cd/As) | <1ppm (each) | FDA/REACH |

| ISO/FDA/ANSI/SGS Certification | Yes | International |

| Lifespan (in formulation) | >8 years (makeup) | - |

Comparison Chart: HC40 Synthetic Mica vs Natural Mica

5. Manufacturing Process: Synthetic Mica Cosmetics (HC40 Model)

- Raw Materials Preparation (Potassium, Magnesium, Alumina, Silica, F/ OH): Strict quality testing — ISO 9001 sampling

- Fusing & Smelting: High-temp (1400-1500°C) melting to create pure synthetic mica substrate

- Annealing & Crystallization: Slow cooling to produce uniform lamellar crystals for high pearl luster

- Pulverizing & Particle Classification: Jet-mill or CNC precision sieving (Custom particle size per makeup spec)

- Pigment Integration / Coating: Iron/titanium/pearlescent coating (per customer needs)

- Heap Aging (optional): Improves structure and color stability

- QC Testing & Packaging: ANSI, REACH standards. Every batch traceable

6. Application Scenarios: Synthetic Mica Cosmetics & Beyond

- Makeup with Synthetic Mica: Eye shadows, blushers, highlighters, lipsticks (FDA, REACH-compliant)

- Premium Coatings: UV-resistant, anti-yellowing automotive/interior paints

- Plastic Masterbatch: Enhanced anti-aging, flame retardancy for electronic appliances

- Industrial Sectors: Stone/petrochem, metallurgy, advanced water treatment—corrosion/abrasion-resistant surface protection

- Functional Films: Cosmetic film/sheet, insulation, and luxury paper

HC40 Synthetic Mica is the backbone of many leading synthetic mica cosmetics brands, offering vibrant, hypoallergenic, and long-lasting performance.

7. Case Studies: Custom Solutions & User Testimonials

Case Study 1: Sustainable Makeup Brand Adoption

-

Client: Leading EU Vegan Cosmetics Brand (NDA protected)

Challenge: Eliminate heavy metal contamination and ensure 100% ethical sourcing trace for new product line

Solution: HC40 Synthetic Mica customized at 18~80μm, batch-certified to ISO 9001/FDA standards

Result: Passed EU cosmetics regulatory tests, achieved 27% increase in product shelf-life, received PETA/Environmental certifications

Case Study 2: Specialty Coatings Manufacturer

-

Client: Fortune 500 Chemical Company

Application: UV & thermal-resistant industrial paints

Solution: Integration of HC40 mica with custom pigment, passing SGS, EN14037 heat/aging cycle tests

Result: 15% reduction in pigment cost, zero color fade after 2000 hours QUV test, improved gloss retention (>90%)

Selected Customer Feedback ★

- "True pearl brilliance, consistent quality batch-to-batch for 2 years! Makes our vegan eyeshadow world-class." — US Indie Makeup Brand PM

- "Responsive after-sales, technical docs all in English, full REACH paperwork provided. Highly recommended." — EU Regulatory Manager

- "No irritation, super smooth texture – end-users love our new lipstick with synthetic mica!” — Director of Formulations, APAC

8. Official Certifications, Partnership, Warranty & Support

- Certifications: ISO 9001, FDA, REACH, SGS, EN 14037, PETA Vegan, EN 71

- Key Clients & Partners: Serves 38 countries | 18 years experience | used by 12+ multinational brands

- Lead Time: Samples in 3–7 days; bulk order 14–25 days (custom specs may extend)

- Quality Assurance: 3 years warranty (batch-level quality); full customer technical support, rapid response (≤24h)

- Support: Free technical documentation, MSDS, ROHS/REACH paperwork on demand

- Traceability: Each batch is uniquely marked & retrievable up to 5 years

9. FAQ: Professional Knowledge Base

Q1: What material is synthetic mica made of?

Synthetic mica, especially HC40, is composed chiefly of phlogopite (synthetic potassium magnesium aluminum silicate), delivering >99.6% purity and zero natural impurities.

Q2: How does synthetic mica differ from natural mica in cosmetics?

Synthetic mica is manufactured in controlled environments, yields higher purity, more consistent platelets, and avoids ethical issues (no child labor)—unlike often variable natural mica.

Q3: What certifications are necessary for synthetic mica cosmetics?

Synthetic mica cosmetics must comply with FDA (US), REACH (EU), ISO 9001 (quality), and heavy metal content standards such as <1ppm Pb/Cd/As (ANSI/SGS lab reports).

Q4: What are typical particle size specifications for makeup with synthetic mica?

Ranges from 5μm (ultrafine for lipsticks) up to 120μm (coarse pearlescent for highlighters). HC40 mica can be tailor-cut to precise customer needs via CNC sieving.

Q5: How is quality ensured?

Each batch is tested according to ISO, FDA, and REACH standards, with full traceability, color/luster/elements checks, and certificates of analysis (COA).

Q6: What is the service life of synthetic mica pigments in cosmetic formulations?

When stored and formulated correctly, synthetic mica pigments offer color and structure stability for 8+ years—much longer than traditional pearl or natural mica pigments.

Q7: Can HC40 synthetic mica be used for non-cosmetic industrial sectors?

Absolutely—HC40 is heat/chemically resistant; ideal for anti-corrosion coatings, plastics, functional films, metallurgy, and specialty paper.

10. Further Resources & Industry Citations

- Cosmetics Business: Synthetic mica—A sustainable alternative

- Grand View Research: Synthetic Mica Market Analysis 2023–2030

- ScienceDirect: Synthetic Mica Pigments—Review & Industry Application

- HC40 Synthetic Mica Official Page

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories