Feb . 03, 2025 00:37

Back to list

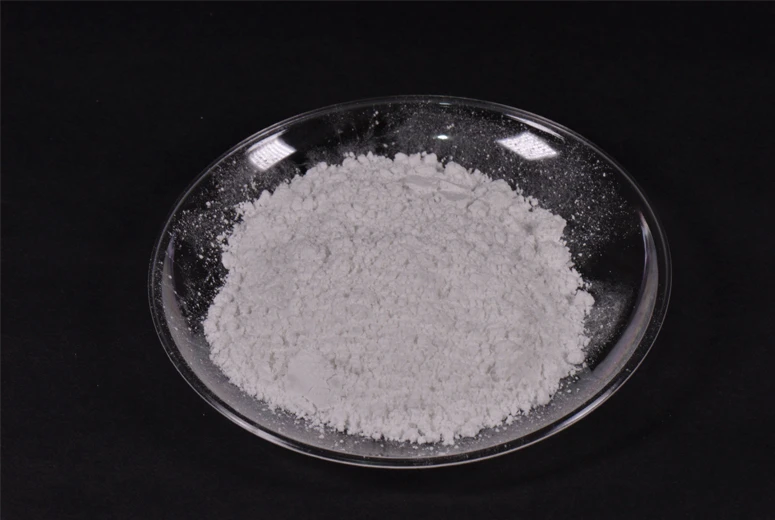

white mica flakes

White mica flakes have piqued the interest of industries globally due to their unique properties and versatility. These naturally occurring mineral flakes are derived from the alteration of aluminum silicate rocks and are predominantly used in products requiring high thermal stability and resistance to corrosion. Manufactured meticulously, white mica flakes serve as an excellent filler material across different sectors, ensuring efficiency and longevity.

In addition to improving product performance, the natural insulating properties of white mica flakes are highly sought after in the electronics industry. Utilized in electronic products, they enhance thermal management, ensuring devices remain cool and functional over prolonged periods. This aspect is particularly crucial in high-performance electronics, where overheating can lead to malfunctions or potential safety hazards. By providing reliable insulation, white mica flakes enhance the reliability and lifespan of electronic components, making them indispensable in modern manufacturing. The extraction and processing of white mica flakes uphold sustainable practices, a quality that significantly elevates their trustworthiness. Companies conscious of their environmental impact actively seek materials that comply with stringent environmental protocols. White mica production not only adheres to these standards but also often contributes to local economies, supporting communities involved in the mining and processing supply chain. To sum up, white mica flakes offer an irreplaceable advantage across various industries due to their unparalleled properties and versatility. Their ability to enhance the aesthetics in beauty products, durability in paints, reinforcement in plastics, and insulation in electronics demonstrates their vast applicability and value. Industries desiring to optimize product quality while prioritizing environmental responsibility continue to turn towards white mica flakes, solidifying their place as an authoritative and trusted material in today's market landscape.

In addition to improving product performance, the natural insulating properties of white mica flakes are highly sought after in the electronics industry. Utilized in electronic products, they enhance thermal management, ensuring devices remain cool and functional over prolonged periods. This aspect is particularly crucial in high-performance electronics, where overheating can lead to malfunctions or potential safety hazards. By providing reliable insulation, white mica flakes enhance the reliability and lifespan of electronic components, making them indispensable in modern manufacturing. The extraction and processing of white mica flakes uphold sustainable practices, a quality that significantly elevates their trustworthiness. Companies conscious of their environmental impact actively seek materials that comply with stringent environmental protocols. White mica production not only adheres to these standards but also often contributes to local economies, supporting communities involved in the mining and processing supply chain. To sum up, white mica flakes offer an irreplaceable advantage across various industries due to their unparalleled properties and versatility. Their ability to enhance the aesthetics in beauty products, durability in paints, reinforcement in plastics, and insulation in electronics demonstrates their vast applicability and value. Industries desiring to optimize product quality while prioritizing environmental responsibility continue to turn towards white mica flakes, solidifying their place as an authoritative and trusted material in today's market landscape.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories