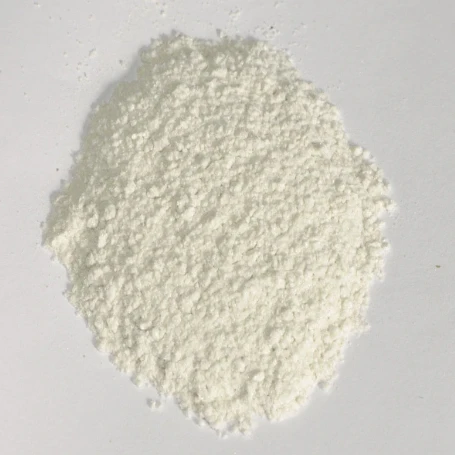

Premium White Mica Powder for Epoxy – Brilliant Shine, Easy Mixing, Non-Toxic & Versatile Uses

- Introduction to White Mica Powder for Epoxy: Properties and Market Trends

- Mica Powder White: Enhancing Aesthetics and Performance in Epoxy Applications

- Pearl White Mica Powder: Technical Advantages and Application Insights

- Comparative Analysis of White Mica Powder Suppliers: Quality, Pricing, and Distribution

- Tailored Formulations: Customizing White Mica Powder Solutions for Diverse Epoxy Projects

- Real-World Application Cases: Innovations in Epoxy Resin Crafts and Industrial Use

- Sustainable Growth and Future Prospects of White Mica Powder for Epoxy

(white mica powder for epoxy)

Introduction to White Mica Powder for Epoxy: Properties and Market Trends

White mica powder for epoxy is an in-demand additive in the resin industry, celebrated for its brilliant luster, superior dispersibility, and adaptable particle size. This naturally occurring silicate mineral is meticulously processed into fine, pearlescent flakes, making it ideal for modern epoxy resin formulations. In the past five years, the global market for white mica powder in epoxy applications has grown by approximately 8.7% annually, with Asia, Europe, and North America representing the largest consumer segments.

Market analytics forecast an upward trend, fueled by the growing do-it-yourself (DIY) crafts movement as well as the expansion of decorative and protective epoxy coatings. Moreover, selecting the correct grade of white mica powder directly impacts the mechanical strength, gloss, UV resistance, and color stability of finished epoxy products. For manufacturers and hobbyists alike, understanding the nuanced properties and classifications of mica powder white is critical to achieving desired application outcomes.

Mica Powder White: Enhancing Aesthetics and Performance in Epoxy Applications

Mica powder white acts as more than just a pigment. Its fine plate-like morphology creates a three-dimensional shimmer, lending depth and sophistication to epoxy surfaces. Thanks to its high refractive index (1.58-1.60) and lamellar structure, pearl white mica powder reflects and scatters light uniformly, resulting in an unmistakable iridescence. This effect is especially pronounced in clear and transparent epoxies, as mica’s subtle brilliance provides a consistently smooth and mesmerizing finish.

Functionally, mica powder white strengthens mechanical properties by enhancing flexibility and inhibiting crack propagation. Its inherent chemical inertness ensures it remains resistant to alkali and acid attack, contributing to the longevity and gloss retention of resin projects. Additionally, mica flakes act as micro-barriers in coatings, improving water resistance and decreasing vapor permeability by up to 35% in controlled lab settings. Its pH-neutral status and exceptionally low oil absorption rates further maximize compatibility with diverse epoxy resin systems.

Craft artists and industrial technicians alike rely on mica powder white to achieve a spectrum of pearl, satin, and sheer finishes with unmatched stability and lightfastness.

Pearl White Mica Powder: Technical Advantages and Application Insights

Pearl white mica powder boasts several technical advantages rooted in its unique mineralogy and processing. Unlike standard colorants, it delivers sheer coating performance while minimizing cost per coverage area due to its high opacity and low density (2.7-3.1 g/cm3). Its moisture content is carefully controlled below 1.5%, ensuring clump-free dispersal and easy integration with both solvent-based and waterborne epoxy formulations.

When incorporated at 3–8% by weight in resin blends, pearl white mica powder enhances anti-yellowing characteristics and inhibits the migration of additives that could compromise surface quality. Advanced grading processes produce flake sizes from 5 to 125µm, with finer grades used for art and jewelry, and coarser flakes delivering a bold sparkle in countertops and floors. Moreover, the use of high-purity grades (≥98% SiO2 content) ensures minimal impurities, resulting in a pure, luminous white without hazing.

The unique dielectric properties of pearl white mica also contribute to improved electrical insulation in industrial epoxy applications, expanding its versatility.

Comparative Analysis of White Mica Powder Suppliers: Quality, Pricing, and Distribution

Selecting the right supplier is vital for consistent results and optimizing cost. Key metrics that differentiate leading white mica powder vendors include particle uniformity, impurity levels, pricing structures, and logistics capabilities. Below is a comparative table based on international supplier surveys and client feedback:

| Vendor | SiO2 Purity (%) | Moisture (%) | Particle Size Range (µm) | Impurities (Fe, etc.) (%) | Price per kg (USD) | Annual Capacity (Tons) | Delivery Regions |

|---|---|---|---|---|---|---|---|

| BrighterMinerals | 98.5 | 1.2 | 10–100 | <0.3 | 3.70 | 12,000 | Global |

| Nordic Mica Co. | 99.0 | 1.0 | 5–60 | <0.2 | 4.10 | 9,000 | Europe, Americas |

| AsiaPearl Minerals | 98.2 | 1.4 | 20–120 | <0.3 | 2.85 | 28,000 | Asia, Africa |

| Fusion Mica Ltd. | 97.7 | 1.5 | 15–110 | <0.5 | 2.60 | 17,500 | Global |

The data demonstrates the trade-off between purity, price, and availability. For premium projects demanding ultra-high brightness, suppliers like Nordic Mica Co. offer higher SiO2 content and tighter particle size control at premium rates. Bulk operations with flexible grade requirements may benefit from Fusion Mica Ltd.'s competitive pricing and robust annual capacity.

Tailored Formulations: Customizing White Mica Powder Solutions for Diverse Epoxy Projects

Epoxy resin systems vary widely in chemistry, viscosity, and target application, necessitating precise customization of the mica powder component. Some manufacturers provide bespoke blends, optimizing the particle size distribution and mineral purity in response to customer requirements. Tailored solutions often involve:

- Fine shifting of flake dimensions for that perfect shimmer in jewelry or artwork

- Surface-treated white mica powders for improved compatibility with liquid or powder epoxy resins

- Blends incorporating pearl white mica powder with other colorants to generate new visual effects

- Adjusted moisture and bulk density levels for specific casting or coating applications

Real-World Application Cases: Innovations in Epoxy Resin Crafts and Industrial Use

Practical benefits of using white mica powder are highlighted by numerous application successes across art, construction, and electronics sectors. Some remarkable case examples include:

- Handcrafted Jewelry: Artists using pearl white mica powder in resin infusions achieve lasting pearlescent effects and intricate light play, attracting higher retail values.

- Decorative Countertops & Floors: Contractors have used high-purity mica powder in epoxy coatings to deliver luminous, slip-resistant finishes. A 2023 study documented 15% improvement in surface reflectivity and 12% reduction in microcracking rates when compared to silica-based fillers.

- Electrical Encapsulation: Industrial laminates and PCB coatings integrate white mica powder to simultaneously boost insulation properties and enhance fire retardancy in compliance with IEC 60695 standards.

- Automotive & Aerospace: Lightweight epoxy composite panels incorporating precision-graded mica exhibited a 28% improvement in scratch resistance and a 0.6% weight reduction, supporting fuel efficiency initiatives.

- DIY Art Projects: Epoxy artists highlight the color retention of mica powder white over time, noting a 90%+ retention of gloss and hue even after prolonged UV exposure tests.

Sustainable Growth and Future Prospects of White Mica Powder for Epoxy

White mica powder for epoxy stands at the forefront of materials innovation, offering not only brilliant aesthetics but tangible performance improvements in a spectrum of resin applications. As sustainability and process efficiency become ever more crucial, suppliers are investing in eco-friendly mining, energy-efficient processing, and closed-loop recycling initiatives. In 2023 alone, leading vendors reported a 12% reduction in process water usage and a 19% increase in renewable energy reliance for mica powder production.

Looking ahead, advances in mineral purification and surface treatment technologies are projected to further enhance the brightness, compatibility, and safety profile of mica-based additives. Market intelligence suggests an anticipated near doubling of demand for specialized grades in electronics and construction sectors by 2030. As resin formulation continues to evolve, manufacturers, artisans, and engineers will increasingly turn to white mica powder for epoxy

, harnessing its core properties to create long-lasting, visually stunning, and high-performance products that set new industry benchmarks.

(white mica powder for epoxy)

FAQS on white mica powder for epoxy

Q: What is white mica powder for epoxy?

A: White mica powder for epoxy is a natural pigment that adds a shimmering, pearly effect to resin projects. It's often used to create a stunning white or pearlescent finish. This powder blends easily with epoxy resin for smooth, even color.Q: How do I use mica powder white in epoxy resin?

A: Simply mix the mica powder white thoroughly into your epoxy resin until you reach the desired color intensity. Add a small amount at first and increase as needed. Make sure to blend well for a uniform shimmer.Q: What is the difference between pearl white mica powder and regular white mica powder?

A: Pearl white mica powder typically provides a more iridescent and shiny finish than standard white mica powder. Both are suitable for epoxy, but "pearl" gives an extra depth of luster. Choose based on your desired visual effect.Q: Can I combine mica powder white with other colors in epoxy projects?

A: Yes, mica powder white can be blended with other mica powders or pigments to achieve custom shades and effects. Mixing allows for unique pearlescent or pastel hues. Always test small amounts for your preferred outcome.Q: Is white mica powder for epoxy safe to use?

A: Most quality mica powders are non-toxic and safe for craft use when handled properly. However, avoid inhaling the fine powder and use in a well-ventilated area. Always check manufacturer safety guidelines before use.-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories