Feb . 07, 2025 05:21

Back to list

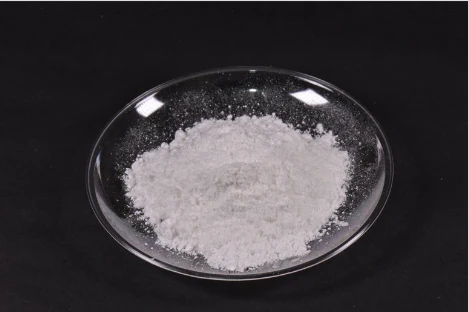

D-5 MICA

Mica, an exceptional mineral, finds widespread use across various industries due to its unique properties. Its versatility and effectiveness make it an indispensable component in numerous applications, driven by real-world insights and specialist knowledge.

Mica is also integral in the production of plastics and rubber, where it enhances strength, thermal, and UV stability. These properties are crucial for producing durable goods that sustain prolonged exposure to environmental factors. Experts within the plastics domain recognize mica's role in reducing material costs while maintaining quality, making it a valued addition in creating reliable consumer products. In addition, mica is favored in the oil and gas industry. Drilling engineers utilize its properties to cool tools, lubricate drill bits, and maintain pressure in drilling muds. Its heat resistance and unique layering help manage intense conditions encountered in extraction processes, thus improving operational efficiency and safety. Authorities in the field highlight how mica contributes to sustainable practice by enhancing resource management and reducing operational risks. Furthermore, mica's applications extend into personal care products, where it functions as a thickening agent in lotions and creams. Its transparency and light-reflecting quality add a luxurious feel to products while ensuring they deliver on moisturizing claims. Dermatologists and product formulators rely on mica to provide consumers with trustworthy and effective skincare solutions that meet dermatological standards. In summary, mica’s multifaceted applicability across industries is a testament to its unrivaled properties and the expertise driven by its use. Its role as an insulator, colorant, enhancer, and protector demonstrates its versatility and indispensability in product manufacturing. Continuous innovation and research by professionals across fields ensure mica retains its status as a vital component that consumers and manufacturers can depend on. Through responsible sourcing and application, mica not only boosts product performance but also upholds sustainability, offering environmentally sound solutions in today's complex market landscape.

Mica is also integral in the production of plastics and rubber, where it enhances strength, thermal, and UV stability. These properties are crucial for producing durable goods that sustain prolonged exposure to environmental factors. Experts within the plastics domain recognize mica's role in reducing material costs while maintaining quality, making it a valued addition in creating reliable consumer products. In addition, mica is favored in the oil and gas industry. Drilling engineers utilize its properties to cool tools, lubricate drill bits, and maintain pressure in drilling muds. Its heat resistance and unique layering help manage intense conditions encountered in extraction processes, thus improving operational efficiency and safety. Authorities in the field highlight how mica contributes to sustainable practice by enhancing resource management and reducing operational risks. Furthermore, mica's applications extend into personal care products, where it functions as a thickening agent in lotions and creams. Its transparency and light-reflecting quality add a luxurious feel to products while ensuring they deliver on moisturizing claims. Dermatologists and product formulators rely on mica to provide consumers with trustworthy and effective skincare solutions that meet dermatological standards. In summary, mica’s multifaceted applicability across industries is a testament to its unrivaled properties and the expertise driven by its use. Its role as an insulator, colorant, enhancer, and protector demonstrates its versatility and indispensability in product manufacturing. Continuous innovation and research by professionals across fields ensure mica retains its status as a vital component that consumers and manufacturers can depend on. Through responsible sourcing and application, mica not only boosts product performance but also upholds sustainability, offering environmentally sound solutions in today's complex market landscape.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories