Feb . 19, 2025 11:41

Back to list

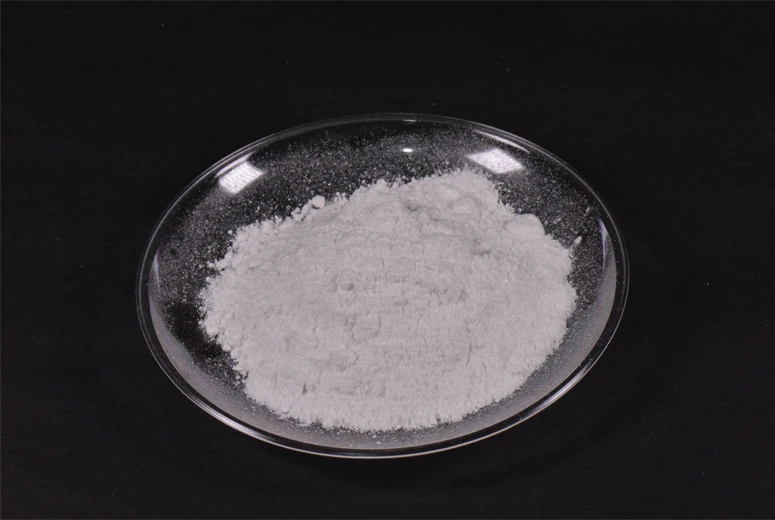

40-D Mica Powder

Mica powder, a versatile and shimmering substance, has captivated industries ranging from cosmetics to industrial applications due to its multifaceted properties. The secret to its appeal lies in its unique composition and the meticulous processes involved in its production. Understanding what mica powder is made out of grants insights into why it is so prized across various domains.

The importance of purity cannot be overstated in the manufacturing of mica powder. Contaminants are meticulously removed to guarantee that the powder retains its desirable qualities. Advanced technologies, including air classification and flotation, are employed to isolate and eliminate impurities. The purity of mica powder directly influences its performance, particularly in high-demand areas such as its use in electronic insulation or as an additive in paints and coatings to enhance durability and UV resistance. Moreover, the inherent natural beauty of mica powders is often augmented through various treatments. Pigmentation is a common practice, where mineral pigments are added to the mica powder to produce a spectrum of colors. These pigments, such as titanium dioxide, adhere to the mica platelets, creating iridescent effects that are highly sought after in decorative arts, cosmetics, and automotive paint. The expansive utility of mica powder, underscored by its luminosity and stability, is deeply rooted in its mineralogical composition. From providing silky textures in makeup products to enhancing the thermal and electrical insulation in industrial settings, mica powder exemplifies how naturally occurring minerals can be harnessed through expert processing and technological precision. For anyone exploring the use of mica powder, recognizing the intricacies of its composition and processing provides an appreciation for why it stands as a cornerstone in both creative and technical industries. The trusted reliability of mica powder is owed to both its natural origins and the sophisticated advancements in its refinement. This understanding not only elevates consumer confidence but also underscores the enduring relevance of minerals in modern product innovation.

The importance of purity cannot be overstated in the manufacturing of mica powder. Contaminants are meticulously removed to guarantee that the powder retains its desirable qualities. Advanced technologies, including air classification and flotation, are employed to isolate and eliminate impurities. The purity of mica powder directly influences its performance, particularly in high-demand areas such as its use in electronic insulation or as an additive in paints and coatings to enhance durability and UV resistance. Moreover, the inherent natural beauty of mica powders is often augmented through various treatments. Pigmentation is a common practice, where mineral pigments are added to the mica powder to produce a spectrum of colors. These pigments, such as titanium dioxide, adhere to the mica platelets, creating iridescent effects that are highly sought after in decorative arts, cosmetics, and automotive paint. The expansive utility of mica powder, underscored by its luminosity and stability, is deeply rooted in its mineralogical composition. From providing silky textures in makeup products to enhancing the thermal and electrical insulation in industrial settings, mica powder exemplifies how naturally occurring minerals can be harnessed through expert processing and technological precision. For anyone exploring the use of mica powder, recognizing the intricacies of its composition and processing provides an appreciation for why it stands as a cornerstone in both creative and technical industries. The trusted reliability of mica powder is owed to both its natural origins and the sophisticated advancements in its refinement. This understanding not only elevates consumer confidence but also underscores the enduring relevance of minerals in modern product innovation.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories