Feb . 10, 2025 11:31

Back to list

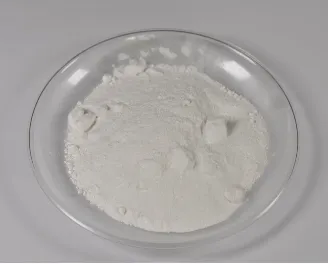

mica dust

Understanding mica dust is critical for those involved in industries where this mineral plays a pivotal role. As a silicate mineral comprising thin, flat crystals, mica is commonly used due to its exceptional chemical, physical, electrical, and thermal properties. However, the rising concern around mica dust arises from its health and environmental implications.

For increased trustworthiness, companies involved in mica-related industries must enforce transparency concerning mica sourcing and processing. Reports have surfaced concerning unethical practices in mica procurement, particularly child labor in mining. Brands committing to ethical sourcing are more likely to gain consumer trust. Furthermore, adherence to environmental regulations, such as safe disposal methods for mica waste, is crucial to prevent soil and water contamination. In applications, mica dust finds its functional significance in specialized products despite the noted risks. It enhances the shimmering quality of cosmetics, adds durability to paints, and serves as an electrical insulator in electronics. Manufacturers are now tasked to innovate with mica alternatives or safer processing methods to align with consumer and environmental standards. Anyone dealing with mica dust, from industrial workers to product developers, must remain informed and vigilant about the risks involved. Education and training programs aimed at recognizing symptoms of dust-related illnesses and executing emergency protocols can further safeguard the workforce. As industries move toward more sustainable and health-conscious practices, the future handling of mica dust is likely to become increasingly regulated, ensuring safer environments for both nature and humanity.

For increased trustworthiness, companies involved in mica-related industries must enforce transparency concerning mica sourcing and processing. Reports have surfaced concerning unethical practices in mica procurement, particularly child labor in mining. Brands committing to ethical sourcing are more likely to gain consumer trust. Furthermore, adherence to environmental regulations, such as safe disposal methods for mica waste, is crucial to prevent soil and water contamination. In applications, mica dust finds its functional significance in specialized products despite the noted risks. It enhances the shimmering quality of cosmetics, adds durability to paints, and serves as an electrical insulator in electronics. Manufacturers are now tasked to innovate with mica alternatives or safer processing methods to align with consumer and environmental standards. Anyone dealing with mica dust, from industrial workers to product developers, must remain informed and vigilant about the risks involved. Education and training programs aimed at recognizing symptoms of dust-related illnesses and executing emergency protocols can further safeguard the workforce. As industries move toward more sustainable and health-conscious practices, the future handling of mica dust is likely to become increasingly regulated, ensuring safer environments for both nature and humanity.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories