Feb . 04, 2025 01:48

Back to list

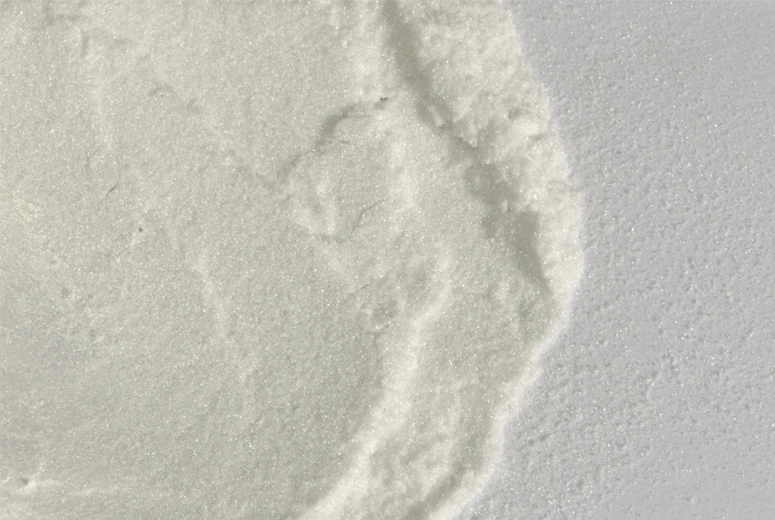

types of mica

Mica, a naturally occurring mineral, is renowned for its remarkable thermal and electrical insulating properties, making it a versatile component in various industrial applications. Understanding the different types of mica can significantly enhance product knowledge for manufacturers and consumers alike, facilitating informed decision-making in both purchase and application processes.

The global demand for mica and its derivatives is witnessing a steady increase, propelled by advancements in electronics, automotive, and renewable energy sectors. Ethically sourcing mica has become a focal point, with industries recognizing the importance of sustainable practices. Ensuring transparency in supply chains not only enhances a company's reputation but also builds trust with consumers increasingly aware of ethical sourcing issues. Engaging with technological advancements, some companies are delving into the synthesis of synthetic mica. This engineered alternative mirrors the properties of natural mica but offers consistent quality and purity, with the added benefit of alleviating reliance on mined materials. Synthetic mica caters to industries where precise specifications and consistency are paramount, such as in the fabrication of specialty paints and coatings. For businesses in sectors utilizing mica, understanding the nuances between these types and their respective applications is imperative. Selecting the correct type of mica not only optimizes the performance and efficiency of products but also aligns with modern trends in sustainability and ethical sourcing. In conclusion, mica's versatility across various industries is a testament to its unmatched properties. Companies that leverage deep insights into the types of mica available can gain a competitive edge, foster trust through sustainable practices, and enhance their authority as leaders in their respective domains. The ongoing innovations and ethical considerations surrounding mica usage signal a promising future for industries willing to adapt and evolve.

The global demand for mica and its derivatives is witnessing a steady increase, propelled by advancements in electronics, automotive, and renewable energy sectors. Ethically sourcing mica has become a focal point, with industries recognizing the importance of sustainable practices. Ensuring transparency in supply chains not only enhances a company's reputation but also builds trust with consumers increasingly aware of ethical sourcing issues. Engaging with technological advancements, some companies are delving into the synthesis of synthetic mica. This engineered alternative mirrors the properties of natural mica but offers consistent quality and purity, with the added benefit of alleviating reliance on mined materials. Synthetic mica caters to industries where precise specifications and consistency are paramount, such as in the fabrication of specialty paints and coatings. For businesses in sectors utilizing mica, understanding the nuances between these types and their respective applications is imperative. Selecting the correct type of mica not only optimizes the performance and efficiency of products but also aligns with modern trends in sustainability and ethical sourcing. In conclusion, mica's versatility across various industries is a testament to its unmatched properties. Companies that leverage deep insights into the types of mica available can gain a competitive edge, foster trust through sustainable practices, and enhance their authority as leaders in their respective domains. The ongoing innovations and ethical considerations surrounding mica usage signal a promising future for industries willing to adapt and evolve.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories