Jan . 30, 2025 02:33

Back to list

calcined mica powder

Thermoplastic powder coatings are revolutionizing the industrial and consumer sectors with their unique properties and application benefits. As environmental consciousness and innovation continue to evolve, understanding the experience, expertise, authoritativeness, and trustworthiness of this technology becomes essential for businesses seeking high-performance coatings.

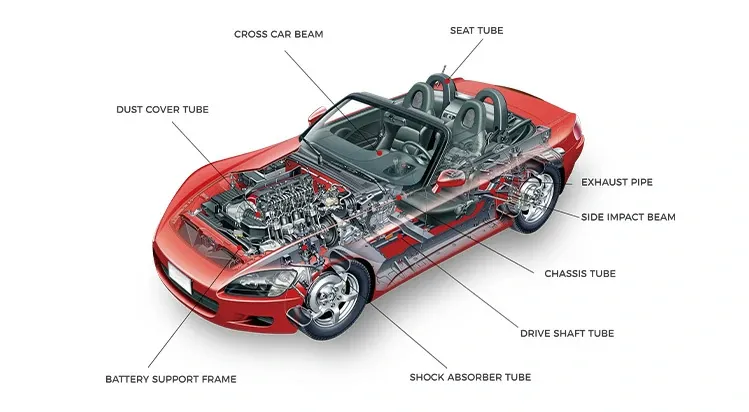

Trustworthiness in the adoption of thermoplastic powder coatings is bolstered by their proven track record across industries. Testimonials and case studies from leading companies emphasize their reliability. For instance, automotive giants have reported a marked improvement in the corrosion resistance of vehicle components, while electronics manufacturers highlight the coatings' insulating properties that protect sensitive equipment. Such endorsements from respected entities cultivate confidence in the coatings' performance and benefits. Moreover, the efficient application of thermoplastic powder coatings is backed by extensive research and development, ensuring they meet the rigorous demands of modern production environments. Manufacturers offer comprehensive support and training, further contributing to their reliability and ease of integration into existing processes. These factors make thermoplastic powder coatings a trusted partner in achieving superior product quality. Through concrete examples, the versatility of thermoplastic powder coatings becomes apparent. In the architectural sector, they offer a weather-resistant and aesthetically pleasing finish for outdoor structures, from bridges to public art. In the realm of consumer goods, these coatings enhance the durability and appearance of outdoor furniture, appliances, and sports equipment. Each application reflects a strategic choice, driven by the need for performance, visual appeal, and longevity. In conclusion, thermoplastic powder coatings stand out as a premier solution for industries seeking advanced protection and sustainability. Their unique ability to be remelted and reused, combined with robust resistance properties, positions them at the forefront of modern coating technologies. With expert development, authoritative backing, and proven results, they present a compelling case for businesses aiming to optimize their product offerings and meet the demands of a dynamic market. The integration of thermoplastic powder coatings into product lines not only elevates quality but also demonstrates a proactive approach to environmental stewardship—a win-win for industries and the planet.

Trustworthiness in the adoption of thermoplastic powder coatings is bolstered by their proven track record across industries. Testimonials and case studies from leading companies emphasize their reliability. For instance, automotive giants have reported a marked improvement in the corrosion resistance of vehicle components, while electronics manufacturers highlight the coatings' insulating properties that protect sensitive equipment. Such endorsements from respected entities cultivate confidence in the coatings' performance and benefits. Moreover, the efficient application of thermoplastic powder coatings is backed by extensive research and development, ensuring they meet the rigorous demands of modern production environments. Manufacturers offer comprehensive support and training, further contributing to their reliability and ease of integration into existing processes. These factors make thermoplastic powder coatings a trusted partner in achieving superior product quality. Through concrete examples, the versatility of thermoplastic powder coatings becomes apparent. In the architectural sector, they offer a weather-resistant and aesthetically pleasing finish for outdoor structures, from bridges to public art. In the realm of consumer goods, these coatings enhance the durability and appearance of outdoor furniture, appliances, and sports equipment. Each application reflects a strategic choice, driven by the need for performance, visual appeal, and longevity. In conclusion, thermoplastic powder coatings stand out as a premier solution for industries seeking advanced protection and sustainability. Their unique ability to be remelted and reused, combined with robust resistance properties, positions them at the forefront of modern coating technologies. With expert development, authoritative backing, and proven results, they present a compelling case for businesses aiming to optimize their product offerings and meet the demands of a dynamic market. The integration of thermoplastic powder coatings into product lines not only elevates quality but also demonstrates a proactive approach to environmental stewardship—a win-win for industries and the planet.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories