Feb . 16, 2025 03:52

Back to list

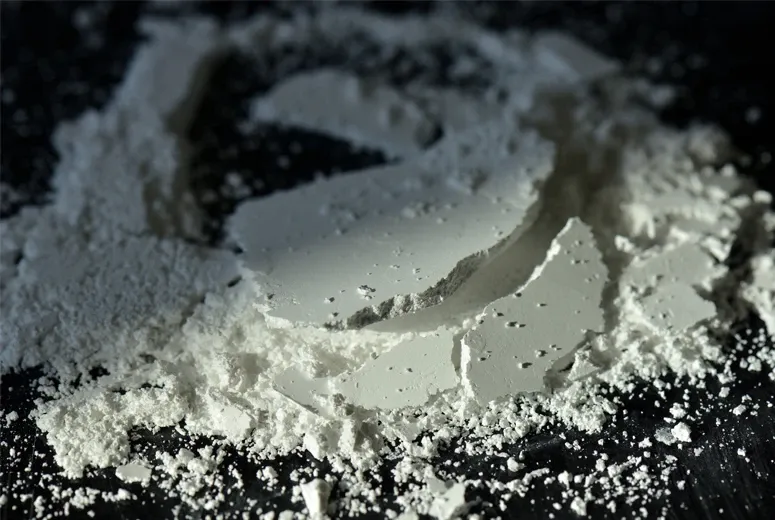

thermoplastic powder coatings

Thermoplastic powder coatings have emerged as a revolutionary solution in the field of surface finishing, offering numerous benefits that traditional liquid coatings struggle to match. Aimed at industries ranging from automotive to architecture, these coatings bring about advantages such as durability, environmental benefits, and cost-effectiveness, which are turning heads globally.

Among the several varieties of thermoplastic powders available, polyvinyl chloride (PVC), nylon, and polypropylene are especially popular due to their distinct properties. PVC coatings are often favored for their excellent resistance to chemicals and moisture, making them ideal for pipelines and valve coatings. Nylon, on the other hand, is appreciated for its toughness and abrasion resistance, commonly applied in areas requiring high wear protection like gears and conveyor systems. Polypropylene offers a compelling balance of strength and flexibility, making it suitable for products that undergo frequent changes in temperature and pressure. From a technical standpoint, expertise in applying thermoplastic coatings is crucial for optimal results. The application requires precision and understanding of the specific powder formulation and the substrate to achieve maximum adhesion and durability. Professional training and the use of advanced equipment are often necessary to meet the highest standards of quality and performance demanded by industry leaders. Companies excelling in this field typically invest in regular staff training and maintain strict process controls, ensuring that they deliver authoritative and trustworthy services consistently. In conclusion, the integration of thermoplastic powder coatings into industrial processes is an innovative leap towards more sustainable, durable, and cost-efficient production methods. As expertise in this area expands and technologies advance, these coatings are poised to become an industry standard, appreciated not only for their robust performance but also for their positive environmental impact. Businesses looking to stay ahead of the curve must consider adopting thermoplastic powder coatings, aligning with global trends towards environmentally responsible manufacturing and upkeep. As the market grows and evolves, staying informed and agile in adapting new practices will be critical for success in this dynamic field.

Among the several varieties of thermoplastic powders available, polyvinyl chloride (PVC), nylon, and polypropylene are especially popular due to their distinct properties. PVC coatings are often favored for their excellent resistance to chemicals and moisture, making them ideal for pipelines and valve coatings. Nylon, on the other hand, is appreciated for its toughness and abrasion resistance, commonly applied in areas requiring high wear protection like gears and conveyor systems. Polypropylene offers a compelling balance of strength and flexibility, making it suitable for products that undergo frequent changes in temperature and pressure. From a technical standpoint, expertise in applying thermoplastic coatings is crucial for optimal results. The application requires precision and understanding of the specific powder formulation and the substrate to achieve maximum adhesion and durability. Professional training and the use of advanced equipment are often necessary to meet the highest standards of quality and performance demanded by industry leaders. Companies excelling in this field typically invest in regular staff training and maintain strict process controls, ensuring that they deliver authoritative and trustworthy services consistently. In conclusion, the integration of thermoplastic powder coatings into industrial processes is an innovative leap towards more sustainable, durable, and cost-efficient production methods. As expertise in this area expands and technologies advance, these coatings are poised to become an industry standard, appreciated not only for their robust performance but also for their positive environmental impact. Businesses looking to stay ahead of the curve must consider adopting thermoplastic powder coatings, aligning with global trends towards environmentally responsible manufacturing and upkeep. As the market grows and evolves, staying informed and agile in adapting new practices will be critical for success in this dynamic field.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories