Jan . 26, 2025 08:25

Back to list

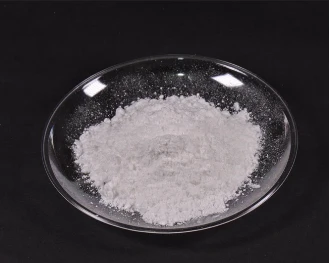

5-25 Micron Synthetic Mica Powder

Rubber synthetic powder, often overshadowed by its more traditional solid forms like sheets and blocks, is rapidly gaining attention in numerous industries due to its versatility and robust properties. This remarkable product is carved out of polymer science innovations and is now pivotal in enhancing the performance and longevity of diverse applications.

Another arena where rubber synthetic powder is making strides is within the electronics industry. As devices become smaller and more complex, the demand for components that provide both flexibility and durability intensifies. Synthetic rubber powder can fulfill such requirements by being a core material in flexible circuits and other applications that require lightweight and adaptable materials. This innovation ensures electronic products are reliable, resilient, and ready to meet the rigorous demands of modern consumers. The expertise behind the production and application of rubber synthetic powder is borne out of decades of research and development in polymer science. Industry experts are continually refining the processes to ensure the highest quality of powder is delivered, each with properties tailored for its intended use. A pivotal aspect of this expertise is understanding the interaction between the powder and other materials, ensuring compatibility and enhancing the final product's properties. Trust in rubber synthetic powder comes not only from its proven track record across various industries but also from its ongoing improvements and refinements. Manufacturers maintain strict quality controls to guarantee consistency and performance, supported by certifications and validations from relevant authorities. The trust is thus twofold—rooted in its scientific development and proven application results. As industries explore new horizons, the role of rubber synthetic powder will undoubtedly expand. The continuous evolution in its applications reinforces its necessity and benefits as a staple resource in multiple sectors. Embracing this innovation allows industries to not only meet current demands but prepare for future challenges with confidence. In summary, rubber synthetic powder is changing the landscape of several industries through its adaptability and performance, cementing itself as a cornerstone for innovation and growth.

Another arena where rubber synthetic powder is making strides is within the electronics industry. As devices become smaller and more complex, the demand for components that provide both flexibility and durability intensifies. Synthetic rubber powder can fulfill such requirements by being a core material in flexible circuits and other applications that require lightweight and adaptable materials. This innovation ensures electronic products are reliable, resilient, and ready to meet the rigorous demands of modern consumers. The expertise behind the production and application of rubber synthetic powder is borne out of decades of research and development in polymer science. Industry experts are continually refining the processes to ensure the highest quality of powder is delivered, each with properties tailored for its intended use. A pivotal aspect of this expertise is understanding the interaction between the powder and other materials, ensuring compatibility and enhancing the final product's properties. Trust in rubber synthetic powder comes not only from its proven track record across various industries but also from its ongoing improvements and refinements. Manufacturers maintain strict quality controls to guarantee consistency and performance, supported by certifications and validations from relevant authorities. The trust is thus twofold—rooted in its scientific development and proven application results. As industries explore new horizons, the role of rubber synthetic powder will undoubtedly expand. The continuous evolution in its applications reinforces its necessity and benefits as a staple resource in multiple sectors. Embracing this innovation allows industries to not only meet current demands but prepare for future challenges with confidence. In summary, rubber synthetic powder is changing the landscape of several industries through its adaptability and performance, cementing itself as a cornerstone for innovation and growth.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories