Reputable Mica Manufacturers

Mica is a versatile and essential material used in a variety of industries, ranging from electronics and automotive to cosmetics and construction. The quality and reliability of mica manufacturers play a crucial role in determining the performance and efficiency of mica-based products. Whether you are in need of high-quality mica for insulation, fire retardant materials, or as a filler for cosmetics, selecting a trusted mica manufacturer ensures that you receive the best material for your application.

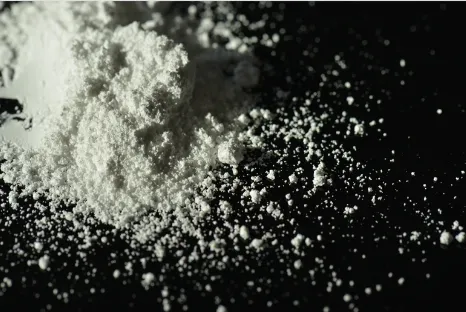

Reputable mica manufacturers understand the technical requirements of various industries and are equipped to provide mica in different forms—such as sheets, powders, and flakes—to suit specific manufacturing processes. High-quality mica is essential for products that need excellent electrical insulation, resistance to heat, and overall durability. Whether you are working on electronics, paints, or construction materials, choosing the right mica manufacturer is essential to guarantee the reliability of your end product.

By working with top-tier mica manufacturers, you not only gain access to premium-quality mica but also benefit from their industry expertise and ability to customize the material to your exact needs. Their in-depth knowledge ensures that you are getting the most out of this versatile mineral for your project.

The Role of a Trusted Mica Manufacturing Company in Global Supply Chains

A reliable mica manufacturing company serves as a key player in the global supply chain, providing businesses with the raw materials necessary for producing a wide range of industrial products. From electronics to cosmetics, mica is used in countless applications due to its unique properties, such as its excellent insulating abilities, resistance to heat, and reflective qualities.

Choosing a trusted mica manufacturing company ensures that you are sourcing high-quality mica that meets the standards required by your industry. Whether you need mica for electrical insulation, paints, or high-performance coatings, an experienced mica manufacturing company has the capacity and expertise to deliver materials that meet the most stringent requirements. These companies also maintain robust quality control measures, ensuring that the mica is processed to the highest standards, free of impurities or defects.

Furthermore, a reputable mica manufacturing company can offer various mica forms and grades to suit different production methods and performance needs. Whether you are sourcing large quantities or need a specific grade for precision applications, working with a skilled mica manufacturing company ensures a seamless supply of quality materials to support your manufacturing processes.

How a Mica Processing Plant Improves Material Quality and Consistency

A well-established mica processing plant plays a crucial role in transforming raw mica into high-quality, usable materials for various applications. The processing plant typically involves several steps, including crushing, grinding, and purifying mica to enhance its properties, making it more suitable for specific uses in the market. Whether for electrical insulation, heat resistance, or decorative purposes, the consistency and quality of the mica produced by a mica processing plant are key to meeting the requirements of different industries.

At a mica processing plant, raw mica is carefully extracted and treated to remove impurities and ensure that it meets industry-specific standards. For example, the plant may apply advanced sorting techniques to select the best mica flakes or use special processing methods to increase the material’s thermal resistance, making it ideal for applications that require high heat tolerance, such as electronics or automotive parts.

By sourcing your mica from a reputable mica processing plant, you are assured of receiving a product that is consistent in quality and meets the technical specifications for your particular needs. These plants adhere to strict quality control measures to ensure that the final product meets both performance and safety standards, making them an essential part of the mica supply chain.

The Benefits of Working with Established Mica Manufacturers for Custom Solutions

When you need customized mica solutions for a specific application, working with established mica manufacturers is your best option. These manufacturers have the expertise to modify the properties of mica to suit a wide variety of needs. Whether you require mica with enhanced electrical insulation properties, increased heat resistance, or a specific texture, experienced mica manufacturers can tailor the material to your exact requirements.

An experienced mica manufacturer can offer a variety of customized options, such as different particle sizes, sheet thicknesses, or processed forms, depending on the needs of your project. For example, if you are in the construction industry, you may require mica for its reflective properties in high-performance paints, whereas in the electronics industry, you may need mica with superior insulating qualities. Regardless of the application, working with established mica manufacturers ensures that you receive mica with the specific attributes required for optimal performance.

Moreover, an established mica manufacturer can provide valuable guidance and insights into the best mica grade or form for your needs, streamlining the sourcing process and helping you avoid unnecessary trial and error. Their ability to deliver consistent and high-quality customized solutions makes them an invaluable partner for any business that relies on mica in their products.

Ensuring Sustainability and Innovation in Mica Manufacturing

As industries increasingly focus on sustainability and environmental responsibility, mica manufacturers are adopting innovative practices to meet these demands. Sustainability is a growing priority in mica extraction and processing, and leading mica manufacturers are incorporating eco-friendly practices throughout their operations. From sourcing mica responsibly to reducing the environmental impact of mining and processing, these manufacturers are setting new standards for sustainable mica production.

Innovation in the mica manufacturing process is also driving efficiency and reducing waste. For instance, advanced processing technologies are allowing manufacturers to produce mica more efficiently, with minimal energy consumption and lower emissions. Many mica manufacturers are also working toward recycling and reusing materials to reduce the need for new raw materials and minimize their carbon footprint.

By choosing mica manufacturers that prioritize sustainability, businesses not only contribute to environmental conservation but also meet the growing consumer demand for eco-friendly products. Whether you are sourcing mica for construction, electronics, or other industries, working with forward-thinking, sustainable mica manufacturers ensures that your supply chain is responsible and innovative, giving your products an edge in the competitive market.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories