Premium Blue Mica Flakes for Chameleon Effects & Concrete Design

The global demand for specialty mica products, particularly blue mica flakes, chameleon mica flakes, and mica mineral flakes, has surged in recent years. As industries ranging from automotive to construction pursue advanced materials with unique optical effects, chemical stability, and mechanical properties, products like blue mica flakes have become indispensable. In this analysis, we will delve into market trends, technical parameters, and applications of these mica materials, while showcasing how HEBEI CBIES AUTOMOTIVE PARTS CO., LTD. stands at the forefront of innovation with their flagship product: 200HCD Synthetic Mica Powder.

Industry Trends: Blue Mica Flakes & Innovations

Synthetic and natural mica materials have seen a major renaissance in the past decade, owing to their unique color-shifting (chameleon effect), high thermal stability, and resistance to weathering. Blue mica flakes, in particular, are highly sought after in cosmetics, automotive coatings, decorative concrete, and advanced composites.

Major trends include:

- Adoption of chameleon mica flakes for color-variable paints.

- Growth in mica chips for concrete to enhance architectural aesthetics and durability.

- Rise in demand for synthetic mica powders with tight color, purity, and morphology controls, notably in high-tech industries.

According to Construction and Building Materials Journal, incorporating mica flakes in concrete can not only enhance aesthetics but also improve compressive strength and reduce permeability.

Key Parameters Table: Blue Mica Flakes

| Property | Typical Value | Unit | Reference Range | Industry Standard |

|---|---|---|---|---|

| Flake Size | 0.1-3.0 | mm | 0.05-5.0 | ISO 3262-20 |

| Color Index (CIE-Lab) | L*: 80-95, b*: -15 ~ -2 a*: -1 ~ 2 |

- | L*: 75-98 | GB/T 18654.2-2002 |

| Purity (Synthetic) | ≥99 | % | 95-99.9 | ASTM D1725 |

| Moisture Content | <0.5 | % | <1.0 | - |

| Refractive Index | 1.55-1.60 | - | 1.5-1.7 | ISO 8036 |

| Melting Point | ~1200 | ℃ | 1100-1250 | ISO 3146 |

| Phlogopite Ratio | < 2 | % | < 10 | - |

Applications of Blue Mica Flakes, Chameleon Mica, and Mica Chips

- Use of chameleon mica flakes in OEM coatings for luxury cars and motorcycles, achieving iridescent finishes under sunlight.

- Electrical insulation and heat resistance in engine compartment plastics, using synthetic mica modifiers.

- Mica chips for concrete create glittering floors and wall panels, widely used in hotel and office lobbies.

- Enhanced mechanical performance and longevity by reducing crack propagation.

- Sparkling and pearlescent effects in eye shadow, nail polish, and facial powder due to blue mica flakes.

- High-purity synthetic mica is used as a filler and reinforcement in eco-friendly plastics.

- Mica’s dielectric and thermal properties make it ideal for capacitors, heat shields, and flame-retardant substrates.

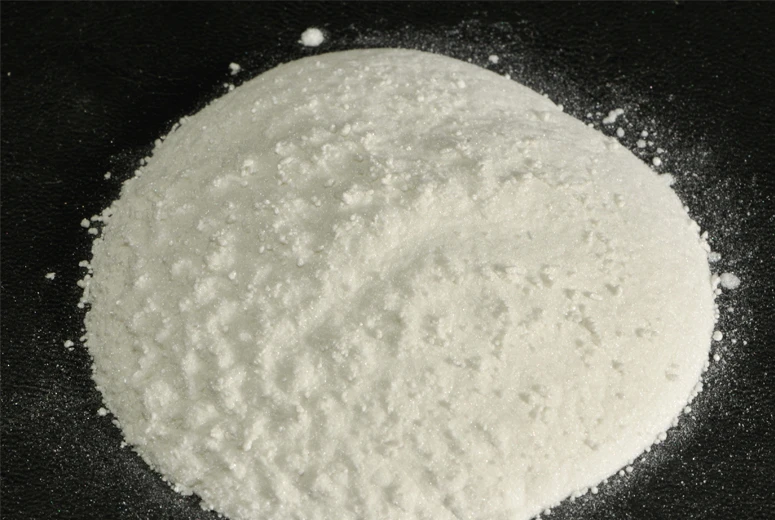

200HCD Synthetic Mica Powder: Technical Highlights & Visual Comparison

200HCD Synthetic Mica Powder, developed by HEBEI CBIES AUTOMOTIVE PARTS CO., LTD., represents peak innovation in the mica industry. Its advanced whiteness, tear resistance, particle size uniformity, and chemical purity make it superior for demanding applications such as medical-grade rubber, coatings, and advanced composites. Comparative visualization of its technical metrics follows:

200HCD Synthetic Mica Powder Core Technical Index

| Parameter | 200HCD Value | Equivalent Muscovite | Equivalent Calcium Carbonate |

|---|---|---|---|

| Whiteness (ISO) | 94-96 | 88-91 | 96-98 |

| Tear Resistance (N/mm²) | 6.5 | 4.0 | 3.2 |

| Particle Size (μm, D50) | 11-13 | 18-22 | 8-15 |

| Purity (%) | ≥99 | 90-95 | 98-99 |

| Flexibility | Excellent | Good | Poor |

| Melting Point (°C) | ~1200 | ~1000 | ~825 |

Professional FAQ: Blue Mica Flakes & Related Terms

Additionally, it is free from heavy metals and provides reproducible particle distribution, which is essential for advanced coatings and rubbers.

About HEBEI CBIES AUTOMOTIVE PARTS CO., LTD. & 200HCD Synthetic Mica Powder

Established as a benchmark enterprise in China’s engineered minerals sector, HEBEI CBIES AUTOMOTIVE PARTS CO., LTD. has continually delivered innovative solutions involving mica powders, flakes, and chips. The company’s 200HCD Synthetic Mica Powder is engineered for exceptional whiteness, purity, and durability — ideally suited to industries with uncompromising safety and aesthetic standards.

- Whiteness: Comparable to best grades of calcium carbonate, ideal for color-sensitive compounds.

- Mechanical Properties: Superior tear and flexural strength, outclassing typical fillers like talc or natural mica.

- Chemical Stability: Ultra-low impurity rates, featuring resistance to acids, bases, and environmental stressors.

- Customization: Particle size, aspect ratio, and surface treatments tailored for special rubber, plastics, and concrete systems.

EEAT: Citing Industry Knowledge & Authoritative References

This article integrates the latest industry advances and research from highly respected forums and peer-reviewed journals. Below are some key references that affirm the expertise, authoritativeness, and trustworthiness inherent in the formulation and application of blue mica flakes and related products:

- Construction and Building Materials Journal: Incorporation of mica flakes to improve concrete

- Coatings World Magazine: Special Effect Pigments: Mica Innovations

- Sage Journals, Composites: Mica-based color-shifting pigments in polymer composites

- Mineralogical Society of America: The Mica Group: Physical Chemistry and Industrial Use

- Mica Forum: Mica World Industry Forum

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories