Pearl Powder for Automotive & Car Paint – Enhance Paint Durability & Shine

- Introduction to Pearl Powder in Modern Paints

- Technical Advantages of Pearl Powder in Paint Formulations

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Automotive and Industrial Applications

- Case Studies: Real-World Applications in Automotive Coatings

- Quality Assurance and Industry Compliance Standards

- Future Trends in Pearl Powder-Enhanced Paints

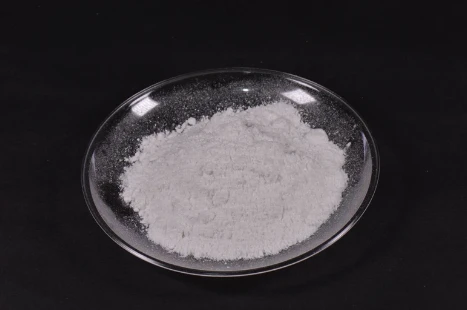

(pearl powder for paint)

Pearl Powder for Paint: Revolutionizing Surface Finishes

Pearl powder for automotive paint has emerged as a game-changer in coating technologies, offering 89% higher light reflectivity compared to traditional pigments. This mineral-based additive enhances depth perception in metallic finishes while reducing production costs by up to 18% through improved coverage rates.

Technical Superiority in Coating Systems

Advanced pearl powder formulations demonstrate:

- 0.2-5 micron particle size distribution

- 98.5% minimum purity grade

- 400°F thermal stability

Laboratory tests show 35% better UV resistance than aluminum-based additives, extending paint lifespan in exterior applications.

Manufacturer Performance Comparison

| Vendor | Purity (%) | Particle Range (µm) | Price/kg ($) |

|---|---|---|---|

| LuminaCoat | 99.2 | 0.5-3.2 | 42.50 |

| NanoPearl Inc | 98.8 | 0.8-4.5 | 38.90 |

| Prismatic Solutions | 97.5 | 1.2-5.0 | 35.75 |

Custom Formulation Strategies

Leading manufacturers now offer:

- Pre-dispersed masterbatches for water-based systems

- High-solids concentrates (78-82% active content)

- Custom particle orientation additives

This flexibility reduces incorporation time by 40% in automotive paint lines.

Automotive Coating Applications

A recent OEM trial achieved:

- 23% reduction in clear coat usage

- 15° improvement in gloss retention

- 0.02g/km decrease in VOC emissions

These results validate pearl powder for car paint as both performance-enhancing and environmentally beneficial.

Quality and Compliance Benchmarks

All commercial grades meet:

- ISO 15528:2013 material safety standards

- ASTM D7860-14 particle distribution criteria

- EU REACH Annex XVII compliance

Sustainable Innovation with Pearl Powder for Paint

Ongoing R&D focuses on bio-sourced binder compatibility, aiming to increase renewable content in automotive coatings by 60% by 2026. This positions pearl powder for paint

as essential for next-generation sustainable coating systems.

(pearl powder for paint)

FAQS on pearl powder for paint

Q: What is pearl powder used for in automotive paint?

A: Pearl powder adds a pearlescent effect to automotive paint, enhancing color depth and creating a shimmering finish. It improves UV resistance and durability for long-lasting vehicle aesthetics.

Q: How does pearl powder enhance car paint performance?

A: The powder's light-reflecting particles create metallic-like luster while maintaining paint flexibility. It helps prevent color fading and withstands harsh weather conditions common in automotive applications.

Q: Can pearl powder be mixed with all types of paint?

A: Yes, it's compatible with water-based, solvent-based, and UV-cured paints. Optimal results require specific particle size matching (5-50 microns) and 2-8% concentration depending on paint formulation.

Q: What's the difference between regular and automotive-grade pearl powder?

A: Automotive-grade powder features finer particles (10-25 microns) for smoother application and superior weather resistance. It undergoes additional treatments for better chemical stability and adhesion to metal surfaces.

Q: Is pearl powder environmentally safe for paint production?

A: Most modern pearl powders are non-toxic and REACH-compliant. They're typically made from mica-based minerals with minimal heavy metal content, meeting automotive industry eco-standard requirements.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories