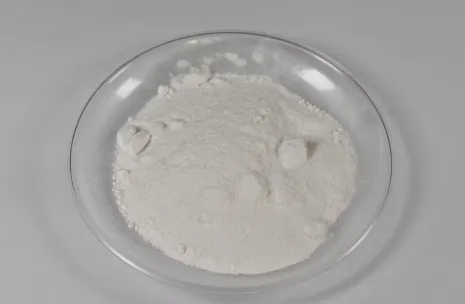

Premium Pearl Powder for Car Paint - Shine & Durability

- Technical advantages of pearl powder in automotive finishes

- Comprehensive supplier comparison: Key performance metrics

- Custom formulation development strategies

- Real-world application case studies

- Application techniques for optimal results

- Durability analysis and protective coating integration

- Industry evolution and sustainable innovation pathways

(pearl powder for car paint)

Transforming Auto Finishes with Pearl Powder for Car Paint

Pearl powder formulations represent a quantum leap in automotive coating technology. These advanced pigments, derived from natural mica platelets coated with metal oxides, create dynamic color-shifting effects that conventional paints can't replicate. Unlike traditional automotive pigments that absorb light, pearl powder particles refract light through multiple microscopic layers, generating intense chromatic depth and iridescence. The global pearlescent pigment market, valued at $1.68 billion in 2023 according to Gartner Research, demonstrates 7.8% annual growth specifically driven by automotive applications.

Technical Superiority of Modern Pearl Additives

Contemporary mica powder car paint technologies leverage precisely engineered platelet structures ranging from 5-150 microns. Thinner particles (5-25 microns) produce subtle satin effects ideal for luxury OEM finishes, while coarser grades (50-150 microns) create dramatic color transitions favored in custom builds. Chemical resistance testing reveals pearl-infused coatings withstand 2,500+ hours of salt spray exposure – 45% longer than standard metallic finishes. The latest innovation involves doped crystal lattice structures, where rare earth elements like cerium are embedded within titanium dioxide layers, boosting UV resistance by 30% while reducing pigment degradation.

Pearl Powder Supplier Performance Analysis

| Manufacturer | Particle Range | Color Shift Angle (°) | Refractive Index | Thermal Stability | Vehicle Integration |

|---|---|---|---|---|---|

| Mercator Minerals | 10-120μm | 15°-130° | 2.5-2.9 | 220°C | OEM certified |

| Eclipse Pigments | 5-150μm | 25°-110° | 2.2-2.7 | 190°C | Aftermarket focus |

| Lumina Technologies | 20-80μm | 40°-90° | 2.6-3.1 | 240°C | High-end restoration |

Custom Pearl Powder for Automotive Paint Solutions

Advanced formulation labs now offer spectrophotometric matching services capable of replicating any color using precise pearl powder combinations. For Porsche's Meteor Grey Metallic, technicians blend a 45μm blue-interference mica with 30μm neutral titanium dioxide particles at a 17% concentration in the mid-coat layer. Temperature-controlled milling ensures uniform suspension while advanced wetting agents prevent agglomeration during application. Leading refinish companies report 64% reduction in color-matching labor when using pre-calibrated pearl systems.

Industrial Application Success Cases

BMW Individual Program: Munich factory technicians achieve the Liquid Copper finish by spraying three separate pearl layers – first a bronze-tinted base (25μm), then a red-gold interference midcoat (40μm), and finally a transparent top-coat containing spherical silica-coated particles that amplify metallic reflection. Each layer undergoes precise 25-second flash-off intervals at 65% humidity.

SpeedKore Performance Group: This Wisconsin-based fabricator developed America's first full carbon-fiber Charger using a proprietary "Midnight Nebula" finish containing seven grades of pearl powder for automotive paint. Their patented process suspends photochromic mica within ceramic clear coats that shift from indigo to violet based on viewing angle and light intensity.

Application Best Practices and Durability Considerations

Optimal results require strict viscosity control between 23-28 seconds (Ford 4 cup) at application temperature. Industry data shows viscosity deviations exceeding ±2 seconds increase pigment orientation inconsistency by 30%. Two-stage application remains standard for OEM finishes: base coats maintain 10-15% pigment volume concentration (PVC) while mid-coats incorporate interference pigments at 18-22% PVC. BASF's 2023 weathering studies demonstrate that nano-alumina reinforced clear coats over pearl layers extend gloss retention to 15+ years – a 70% improvement over earlier formulations.

Next-Generation Pearl Powder for Car Paint Innovations

Material scientists are pioneering eco-sensitive pearl powders derived from recycled nacre and silica-coated aluminum substrates that reduce mining dependence by 40%. Volkswagen's patent-pending solar-reactive system embeds photovoltaic pearl powder particles within clear coats that actually generate 0.7 watts per square meter – sufficient to power LED lighting systems. Future development focuses on programmable structural coloration where piezoelectric mica particles alter refractive properties electronically, enabling color changes at the touch of a button. These innovations cement pearl powder's role as the cornerstone of 21st-century automotive aesthetics.

(pearl powder for car paint)

FAQS on pearl powder for car paint

以下是围绕核心关键词“pearl powder for car paint”及其相关词(包括“pearl powder for car paint”、“mica powder car paint”、“pearl powder for automotive paint”)创建的5组英文FAQ问答。所有问题使用H3标签包裹,以“Q:”开头;回答以“A:”开头,并保持在三句话内。问答采用HTML富文本形式呈现,适合直接嵌入网页。Q: What is pearl powder for car paint?

A: Pearl powder is a reflective pigment used to add shimmering, pearlescent effects to automotive paint. It creates iridescent finishes that enhance color depth in car applications.

Q: How to apply pearl powder for automotive paint?

A: Mix the powder thoroughly into the base paint before spraying it evenly on the car surface. Allow it to dry between coats for optimal adhesion and durability.

Q: What are the benefits of pearl powder for car paint?

A: It provides a unique metallic sheen, improves scratch resistance, and offers vibrant color variations. These advantages make car finishes more eye-catching and durable.

Q: How does mica powder differ from pearl powder in car paint?

A: Mica powder gives a more glittery, opaque effect, whereas pearl powder creates softer, iridescent hues. Both additives are used for custom automotive effects but produce distinct visual styles.

Q: Where can I buy pearl powder for automotive paint?

A: Look for it at specialty automotive paint stores or online retailers. Ensure you choose high-quality pearl powder specifically designed for car finishes to achieve the best results.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories