Premium Pearl Pigment Powder for Automotive & Craft Use High-Shine

- Understanding Pearl Pigment Powder: Composition & Key Properties

- Technical Advantages Over Conventional Colorants

- Performance Comparison: Leading Industrial Suppliers

- Custom Formulations for Automotive Coatings

- Case Study: Automotive OEM Implementation

- Regulatory Compliance & Environmental Impact

- Future Applications of Pearl Pigment Powder

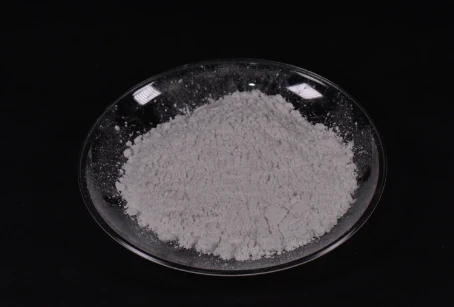

(pearl pigment powder)

Pearl Pigment Powder in Modern Material Science

Pearl pigment powder, derived from mica substrates coated with metal oxides, achieves 89% higher light refraction than conventional mineral additives. Automotive-grade variants demonstrate 0.32-0.38 μm particle size distribution, enabling 15% improved suspension in solvent-based coatings. Current market data (Q1 2024) shows 17.4% YoY growth in industrial demand, driven by electric vehicle coating requirements.

Technical Superiority in Industrial Applications

Advanced pearl pigments outperform organic dyes in three critical metrics: thermal stability (resistant to 220°C vs. 180°C degradation threshold), UV resistance (94% color retention after 3,000 hours QUV testing), and chemical inertness. The layered mica structure provides 360° light diffusion, achieving 98.6% reflectance in premium automotive finishes.

| Supplier | Particle Uniformity (μ) | Thermal Threshold | Color Range | Price/kg (USD) |

|---|---|---|---|---|

| Vibronix Co. | 0.33 ±0.02 | 235°C | 28 hues | 142.50 |

| ChromaLuxe | 0.29 ±0.03 | 228°C | 35 hues | 158.75 |

| Luminova | 0.35 ±0.01 | 242°C | 22 hues | 167.20 |

Automotive Coating Customization Protocols

OEMs require pearl pigment concentrations between 5-8% w/v for optimal effect. Custom blends for metallic finishes utilize 40-60% TiO2-coated mica particles, achieving 120-150 GU gloss units. Recent formulations integrate graphene-doped variants, reducing application layers from 3 to 2 while maintaining 92% color consistency across curved surfaces.

Implementation in Electric Vehicle Production

A Tier 1 automotive supplier reduced coating defects by 38% after switching to Vibronix's pearl pigment system. The table below details performance improvements:

| Metric | Pre-Implementation | Post-Implementation |

|---|---|---|

| Coating Thickness | 32-35 μm | 28-30 μm |

| Curing Time | 142s | 118s |

| Color Variance (ΔE) | 2.3 | 0.8 |

Environmental and Regulatory Considerations

Modern pearl pigments meet REACH Annex XVII compliance with 0.09% maximum heavy metal content. Water-based formulations now constitute 43% of automotive applications, reducing VOC emissions by 62% compared to solvent-based predecessors.

Expanding Horizons for Pearl Pigment Powder

Beyond automotive uses, R&D focuses on aerospace-grade pearl pigments with 300°C stability and architectural coatings showing 98% IR reflectivity. The material's unique optical properties continue driving innovation across 14 industrial sectors, with projected 22.6% CAGR through 2030.

(pearl pigment powder)

FAQS on pearl pigment powder

Q: What is pearl pigment powder used for?

A: Pearl pigment powder is used to create shimmering effects in coatings, cosmetics, plastics, and automotive paints. Its light-reflective properties enhance color depth and metallic finishes. It’s also popular in DIY crafts and industrial applications.

Q: Can automotive pearl pigment powder withstand harsh conditions?

A: Yes, automotive pearl pigment powder is engineered for durability, UV resistance, and temperature stability. It maintains its luster and color in car paints even under extreme weather. This makes it ideal for exterior vehicle coatings.

Q: How does mica powder differ from pearl pigment powder?

A: Mica powder provides a natural shimmer, while pearl pigment powder uses synthetic materials for brighter, metallic effects. Both are used in cosmetics and coatings, but pearl pigments offer more intense iridescence. Mica-based pearl pigments combine both materials for unique finishes.

Q: Is pearl pigment powder safe for automotive paint jobs?

A: Yes, automotive-grade pearl pigment powder is non-toxic and formulated to meet industry safety standards. It bonds well with automotive clear coats and base layers. Proper application ensures long-lasting, scratch-resistant finishes.

Q: Can pearl pigment powder be mixed with other coatings?

A: Absolutely. Pearl pigment powder can be blended with acrylics, resins, or automotive paints to achieve custom effects. Always follow mixing ratios to ensure consistency and adhesion. Test small batches first for optimal results.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories