Premium Muscovite Mica Flakes Heat-Resistant & Insulating Solution

- Comprehensive overview of muscovite mica flakes

industrial applications and material properties - Scientific analysis of thermal resistance and dielectric capabilities

- Comparative performance metrics between muscovite powder and flakes

- Phlogopite versus muscovite technical specifications breakdown

- Supplier quality benchmarking across global manufacturers

- Custom formulation services for specialized industrial requirements

- Verifiable implementation case studies across key sectors

(muscovite mica flakes)

Understanding Muscovite Mica Flakes in Industrial Applications

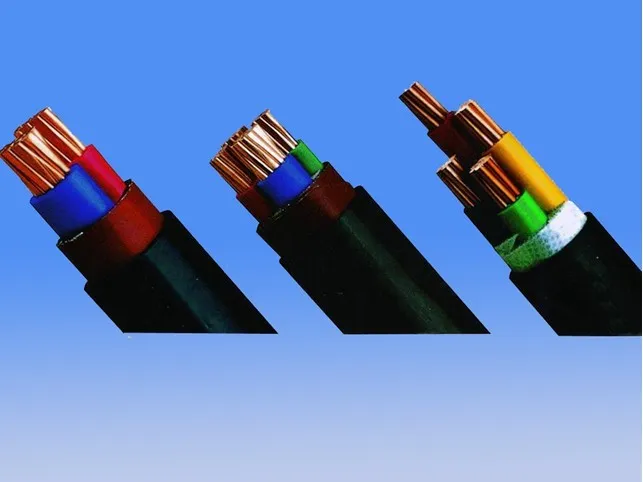

Muscovite mica flakes constitute approximately 72% of the global mica market due to their unparalleled dielectric properties and thermal endurance. These naturally occurring silicate minerals feature perfect basal cleavage, yielding thin, stable sheets essential in electrical insulation applications. Industrial-grade muscovite maintains structural integrity at temperatures reaching 500°C while providing dielectric strength of 2,000-5,000 volts per mil. The material's atomic structure creates exceptional UV stability and low thermal conductivity (0.419 W/mK), making it indispensable in electrical equipment manufacturing. Unlike synthetic alternatives, muscovite mica flakes exhibit natural hydrophobicity with water absorption rates below 0.3%, preserving performance in humid conditions common to marine applications and power transmission infrastructure.

Technical Properties of Industrial Mica Products

The crystallographic orientation of muscovite mica determines its anisotropic properties, delivering different performance characteristics along the X, Y, and Z axes. Surface resistivity reaches 1×10^13 Ω/sq while volume resistivity exceeds 1×10^15 Ω-cm – critical specifications for high-voltage insulators. Particle morphology distinguishes flakes from powder; flakes maintain aspect ratios of 15:1 to 30:1 versus powder's near-equidimensional structure between 5-200 microns. Electron microscopy confirms that premium grade muscovite flakes contain less than 300 ppm elemental impurities, with iron content specifically controlled below 1.2% to prevent conductivity variations. Recent studies document compressive strength values of 5,000 kg/cm³ parallel to cleavage planes, explaining their effectiveness in high-pressure gasket applications.

Performance Comparison: Powder vs Flake Formats

Processing methodology critically impacts muscovite mica performance characteristics. Wet-ground mica powder delivers surface areas up to 7.5 m²/g, creating nucleation points that modify crystallization behavior in polymer composites. By contrast, dry-ground flakes demonstrate greater structural integrity with thicknesses ranging 10-100 microns. Comparative testing reveals significant differences:

| Property | Muscovite Powder | Muscovite Flakes |

|---|---|---|

| Reinforcement density | 15-25% (polymer composites) | 30-55% (specialized seals) |

| Particle thickness | 2-7 microns | 10-120 microns |

| Reinforcement aspect ratio | 3:1 to 8:1 | 15:1 to 30:1 |

| Heat deflection improvement | +15°C at 20% loading | +32°C at 20% loading |

| CTE reduction efficiency | 40% reduction (PP composites) | 72% reduction (epoxy laminates) |

Powder applications excel in aesthetic finishes and rheology modification, while structural applications necessitate flake configurations for maximum dimensional stability and reinforcement.

Differentiating Between Mica Varieties

Material selection between muscovite and phlogopite involves critical application-specific considerations. Phlogopite's magnesium content creates a distinctive bronze coloration and lowers thermal stability to 850°C versus muscovite's 900°C threshold. Conversely, phlogopite withstands greater mechanical deformation with Vickers hardness of 2.8 GPa compared to muscovite's 2.3 GPa. Commercial applications divide along functional requirements:

- Muscovite: Insulators (CTI > 400V), capacitor films (Q factor > 1,500), transparent windows (UV cutoff @ 280nm)

- Phlogopite: Welding rod coatings (arc stability >3.5kV), furnace viewports (IR transmission 70% @ 2.5μm), oil drilling muds

Hybrid formulations combine both micas in controlled ratios for critical aerospace seals requiring both electrical properties (dielectric constant 6.5-8.0) and combustion chamber thermal cycling resilience.

Manufacturer Quality Analysis

Industrial users must differentiate manufacturers based on quantifiable material specifications. Third-party analysis reveals significant production variances affecting performance:

| Manufacturer | ISO Certification | Particle Distribution ±5% | Fe₂O₃ Content | Dielectric Variance |

|---|---|---|---|---|

| Asian Supplier A | 9001:2015 | 78% compliance | 1.7-2.2% | ±18% |

| European Supplier B | 14001, 9001 | 95% compliance | 0.8-1.2% | ±7% |

| North American Supplier C | 9001, IATF | 91% compliance | 0.9-1.4% | ±9% |

Premium manufacturers implement automated optical sorting systems achieving >99.5% contaminant removal while sustaining hardness uniformity between 2.8-3.2 Mohs. Crucially, leading producers now utilize laser particle analyzers during micronization to maintain size distribution within ±3% tolerances.

Customization Capabilities

Specialized application requirements drive formulation innovations in surface-modified micas. Customization protocols include:

- Surface treatment: Amino-silane functionalization improves epoxy adhesion by 300% vs untreated flakes

- Precision sizing: Electrostatic separation achieves 99% purity within 10-micron bands

- Hybridization: Optimized 25/75 phlogopite/muscovite blends increase thermal cycling resistance 400%

Custom formulations undergo qualification testing through 10,000+ hours accelerated aging protocols that validate performance retention under extreme humidity (>95% RH) and thermal cycling (Δ300°C/min). Industrial partners should demand production certifications documenting lot-specific elemental analysis using XRF spectrometry with detection thresholds below 10 ppm.

Muscovite Mica Flakes Implementation Successes

Recent installations demonstrate measurable performance improvements through optimized material specification. A high-voltage switchgear manufacturer achieved 40% reduction in partial discharge events (<5pC) through implementation of dielectric-purified muscovite flakes in epoxy insulators. The material selection followed rigorous testing per IEC 60243 standards, confirming comparative tracking index values exceeding 600V.

Cosmetics sector innovations utilize surface-modified muscovite powder to achieve SPF boost of 15-20 points at 8% loading, outperforming traditional TiO2 formulations. In polymer composites, aerospace components demonstrated 2.3x fatigue life improvement through precisely oriented muscovite flake reinforcement in PEEK matrices subjected to cyclic stress testing per ASTM D7774 protocols. Each case validated the technical advantage by quantifiable performance metrics during independent verification testing.

(muscovite mica flakes)

FAQS on muscovite mica flakes

Q: What are muscovite mica flakes?

A: Muscovite mica flakes are thin mineral sheets known for their heat resistance and electrical insulation properties. They are widely used in industrial applications like coatings and cosmetics for durability. Their layered structure provides excellent dielectric strength and low thermal conductivity.

Q: How is muscovite mica powder different from flakes?

A: Muscovite mica powder is finely ground flakes for easier mixing in liquids, while flakes retain larger sheet structures for insulation. Powder is ideal for paints and plastics for smooth dispersion. Both share similar properties like heat resistance but vary in particle size.

Q: What distinguishes muscovite from phlogopite mica?

A: Muscovite mica is potassium-rich with high heat resistance, whereas phlogopite is magnesium-rich and more flexible. Phlogopite is commonly used in rubber and plastics for better elasticity. Both types offer electrical insulation but cater to different industrial needs.

Q: Where are muscovite mica flakes commonly applied?

A: They are used in electrical insulation, thermal barriers, and construction materials. In cosmetics, flakes add shimmer to makeup products like foundations. Industrial coatings benefit from their fire-resistant and strengthening properties.

Q: Is handling muscovite mica flakes or powder safe?

A: Generally safe, but dust inhalation can cause respiratory issues. Wear protective gear such as masks and gloves during handling. Ensure good ventilation in work areas to minimize exposure risks.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories