Innovative Approaches to Enhancing the Properties of Modified Plastics for Various Applications

Modified Plastics Innovations and Applications

In recent years, the world has witnessed a significant shift towards the development and utilization of modified plastics. As the demand for materials that are more durable, versatile, and environmentally friendly grows, researchers and manufacturers have begun to explore ways to enhance the properties of conventional plastics. Modified plastics are essentially plastics that have been altered from their original form to improve performance characteristics or to make them suitable for specific applications. This article delves into the innovations, benefits, and various applications of modified plastics that are shaping industries today.

Understanding Modified Plastics

Modified plastics result from various processes that enhance the properties of the base material. These modifications may include the incorporation of additives, blending with other polymers, or applying treatments that alter the polymer structure. Common types of modified plastics include composites, filled polymers, and blends. Each of these categories serves a unique purpose and caters to different industry needs.

One noteworthy example is the use of nanomaterials in modifying plastics. The incorporation of nanoparticles can significantly increase the strength, thermal stability, and barrier properties of plastics. This approach has opened new avenues in the manufacturing of lightweight and high-performance materials suitable for aerospace and automotive applications.

Benefits of Modified Plastics

The advantages of modified plastics are manifold. First and foremost, they tend to exhibit enhanced mechanical properties compared to unmodified polymers. For instance, modified plastics can offer improved tensile strength, impact resistance, and flexibility. This is crucial for industries that require materials to withstand harsh conditions or heavy usage.

Another significant benefit is the improved thermal resistance. Modified plastics can be formulated to maintain their integrity in high-temperature environments, making them ideal for applications such as electrical insulation, automotive components, and industrial equipment.

The adaptability of modified plastics also lies in their ability to be engineered for specific functionalities. For example, certain modified plastics can be made to be fire-retardant, UV resistant, or even antimicrobial, broadening their applicability across various fields including medical devices, consumer products, and construction materials.

modified plastics

Applications Across Industries

The versatility of modified plastics means they find applications across numerous sectors. In the automotive industry, for instance, manufacturers are increasingly using modified thermoplastics to produce lighter and more fuel-efficient vehicles. These materials reduce the overall weight of the car while enhancing safety and performance.

In electronics, the demand for modified plastics is skyrocketing due to the need for materials that have superior electrical insulation properties. These modified polymers are used in circuit boards, housing, and other components, ensuring reliability and longevity in electronic devices.

Moreover, the medical field has seen significant advancements thanks to modified plastics. Biocompatible polymers are utilized in medical devices, drug delivery systems, and prosthetics. The customization options available through the modification of these materials allow for innovations that improve patient outcomes and device efficacy.

Environmental Considerations

As sustainability becomes an increasingly pressing issue, the development of modified plastics also addresses environmental concerns. Biodegradable modified plastics are emerging as a solution to combat plastic pollution. These materials can break down more easily in natural environments, reducing the long-term impact on ecosystems.

Additionally, modified plastics can be designed to be more easily recyclable or produced from renewable resources. The ongoing research into bio-based modified plastics seeks to create materials that not only meet industrial standards but also align with the goals of reducing the carbon footprint associated with traditional petroleum-based plastics.

Conclusion

The field of modified plastics is evolving rapidly, driven by technological advancements and the need for innovative solutions across various industries. With their enhanced properties and diverse applications, modified plastics are helping to address some of the most pressing challenges faced by manufacturers today. As research continues and new materials are developed, modified plastics promise to play an even more critical role in a sustainable future, making them an indispensable part of modern technology and industry.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

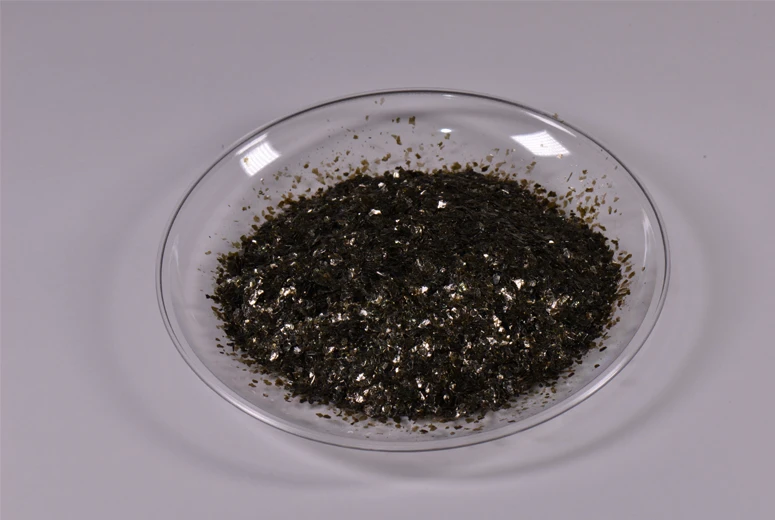

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories