Feb . 18, 2025 10:38

Back to list

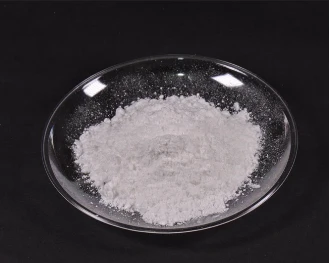

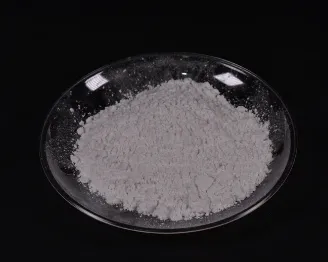

40-D Mica Powder

Evaluating the quality of mica is essential for industries that rely on this shimmering mineral, such as cosmetics, electronics, and the automotive sector. Mica, prized for its reflective properties and versatility, must meet specific quality standards to ensure optimal performance across products. Understanding mica's quality involves a blend of practical experience, technical expertise, authoritative research, and trusted methodologies.

Real-world experience plays an invaluable role in judging mica quality. Industry veterans, who have spent years working with mica, often develop an intuitive understanding of its attributes. They can detect quality variations that might elude less experienced observers, such as subtle changes in luster or texture. Their judgments, honed over decades, instill confidence in the end product. It is also important to trust suppliers who enforce ethical mining practices, as the manner in which mica is obtained affects its quality. Mismanagement or unethical sourcing can introduce impurities and compromise the mineral’s structural integrity. Reputable suppliers regularly audit mining sites, ensuring that workers operate under safe conditions and that the mica is free from contaminants that could degrade its quality. This transparency is crucial, fostering trust between suppliers and end-users and ensuring that the final product is as high-quality as it is ethically produced. In summary, evaluating mica quality demands a comprehensive approach that combines scientific expertise, authoritative resources, and ethical considerations. By employing state-of-the-art testing methods and adhering to international standards, industries can guarantee that their mica is of the highest quality. This, coupled with expert insights born of years of experience, and the assurance of ethical sourcing practices, creates a foundation of trustworthiness that is indispensable in delivering superior products to consumers. As the demand for high-performing, ethically-sourced mica continues to grow, these practices will remain at the forefront of assessing and ensuring mica quality in diverse industries.

Real-world experience plays an invaluable role in judging mica quality. Industry veterans, who have spent years working with mica, often develop an intuitive understanding of its attributes. They can detect quality variations that might elude less experienced observers, such as subtle changes in luster or texture. Their judgments, honed over decades, instill confidence in the end product. It is also important to trust suppliers who enforce ethical mining practices, as the manner in which mica is obtained affects its quality. Mismanagement or unethical sourcing can introduce impurities and compromise the mineral’s structural integrity. Reputable suppliers regularly audit mining sites, ensuring that workers operate under safe conditions and that the mica is free from contaminants that could degrade its quality. This transparency is crucial, fostering trust between suppliers and end-users and ensuring that the final product is as high-quality as it is ethically produced. In summary, evaluating mica quality demands a comprehensive approach that combines scientific expertise, authoritative resources, and ethical considerations. By employing state-of-the-art testing methods and adhering to international standards, industries can guarantee that their mica is of the highest quality. This, coupled with expert insights born of years of experience, and the assurance of ethical sourcing practices, creates a foundation of trustworthiness that is indispensable in delivering superior products to consumers. As the demand for high-performing, ethically-sourced mica continues to grow, these practices will remain at the forefront of assessing and ensuring mica quality in diverse industries.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories