Feb . 18, 2025 12:21

Back to list

40-D Mica Powder

The efficient handling and treatment of materials during manufacturing processes often become critical factors that determine the quality of the finished product. In industries where precision, durability, and performance are critical, mica processing stands out as a specialized procedure requiring both expertise and technological prowess.

The processed mica is then fabricated into different forms and products. This requires authoritative knowledge of the manufacturing and industrial requirements relevant to the product’s intended use. Whether it is layered into thin sheets for electrical insulation or ground into fine powders for use in cosmetics and paints, each application necessitates customized processing techniques. To maintain competitiveness and sustainability in the mica processing industry, continuous research and development are essential. Having a team of experts dedicated to innovating and improving processing techniques can lead to breakthroughs that ensure better resource utilization and improved product quality. Furthermore, maintaining ethical considerations, such as sustainable mining practices and adhering to labor standards, contributes significantly to the trustworthiness of businesses in this industry. Companies leading the mica process field often do so by establishing authoritative credibility through certifications and affiliations with professional bodies. For example, adhering to international standards set by organizations like ISO not only assures product quality but also enhances trust among clients and partners. Investing heavily in R&D not only facilitates innovation but also drives the acquisition of technical expertise among the workforce. This knowledge becomes invaluable, especially when dealing with custom projects or when clients require alterations in the mica properties to suit specific applications. In summary, mastering the mica process is an art that combines experience, technical expertise, innovation, and ethical practices. The relationship between efficient processing and quality assurance defines the competitive edge in today’s market, making it essential for companies to continuously strive for these standards. As businesses focus on improving these aspects, they not only enhance their products' market viability but also solidify their position as industry leaders.

The processed mica is then fabricated into different forms and products. This requires authoritative knowledge of the manufacturing and industrial requirements relevant to the product’s intended use. Whether it is layered into thin sheets for electrical insulation or ground into fine powders for use in cosmetics and paints, each application necessitates customized processing techniques. To maintain competitiveness and sustainability in the mica processing industry, continuous research and development are essential. Having a team of experts dedicated to innovating and improving processing techniques can lead to breakthroughs that ensure better resource utilization and improved product quality. Furthermore, maintaining ethical considerations, such as sustainable mining practices and adhering to labor standards, contributes significantly to the trustworthiness of businesses in this industry. Companies leading the mica process field often do so by establishing authoritative credibility through certifications and affiliations with professional bodies. For example, adhering to international standards set by organizations like ISO not only assures product quality but also enhances trust among clients and partners. Investing heavily in R&D not only facilitates innovation but also drives the acquisition of technical expertise among the workforce. This knowledge becomes invaluable, especially when dealing with custom projects or when clients require alterations in the mica properties to suit specific applications. In summary, mastering the mica process is an art that combines experience, technical expertise, innovation, and ethical practices. The relationship between efficient processing and quality assurance defines the competitive edge in today’s market, making it essential for companies to continuously strive for these standards. As businesses focus on improving these aspects, they not only enhance their products' market viability but also solidify their position as industry leaders.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

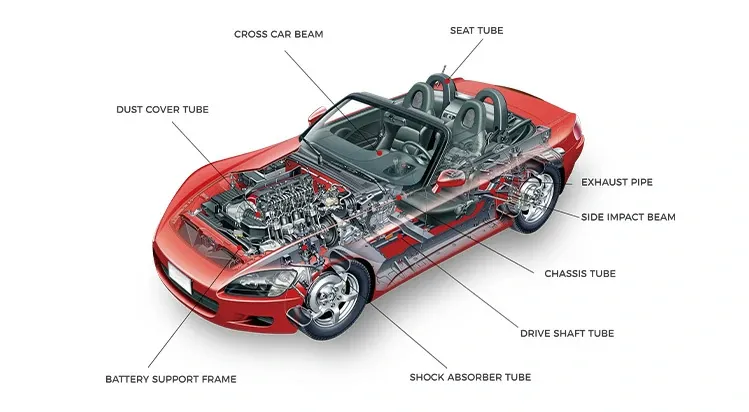

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories