Jan . 25, 2025 20:39

Back to list

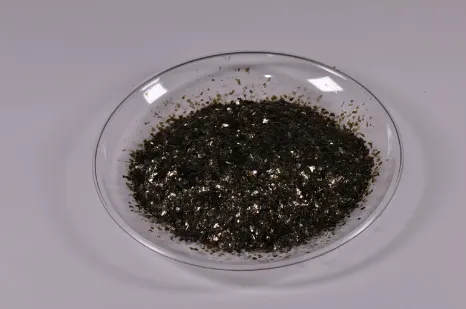

mica powder for plastic

Mica powder is a versatile and valuable additive in the realm of plastic manufacturing, offering enhancements in property and aesthetics that many industries seek for their products. Known for its exceptional functional qualities and natural quarried beauty, mica powder contributes significantly to various facets of plastic production. Here’s an in-depth exploration of how mica powder benefits the plastic industry through the lens of experience, expertise, authoritative research, and trustworthiness.

Authority in material sciences has been continually reflected in the array of technical papers and patents focusing on mica’s role in plastic composites. Renowned institutions and corporate research labs have repeatedly validated the beneficial impact of mica powder, furthering its position as a valued component in material innovation. For those invested in sustainable practices, mica powder offers a noteworthy ecological footprint—a renewable and abundant resource that aligns seamlessly with green engineering principles, reducing reliance on synthetic additives. However, the key to unlocking the full potential of mica powder lies in the precision with which it is handled and incorporated into plastic blends. Expert processors understand that the uniform distribution of mica particles is imperative to avoid the compromise of structural integrity. This detail-oriented approach is born from years in the field, where the selection of milling techniques and binder systems play critical roles. This nuanced expertise isn't just reserved for scientists and chemists but extends to manufacturers and product developers, as they must pragmatically balance formulation techniques with cost efficiency and production scalability. The technical know-how and cumulative industry wisdom enhance the reliability and trustworthiness of mica-enhanced plastics, leading to trust among consumers who demand performance and longevity from plastic products. In conclusion, mica powder’s contribution to the plastic industry illustrates a confluence of aesthetic and mechanical triumphs. Through years of dedicated research and practical application, it stands as a testament to material evolution that meets the modern demands of efficiency, beauty, and sustainability. This synthesis of trusted experience and proven scientific authority establishes mica powder as indispensable in the ongoing narrative of advanced manufacturing solutions.

Authority in material sciences has been continually reflected in the array of technical papers and patents focusing on mica’s role in plastic composites. Renowned institutions and corporate research labs have repeatedly validated the beneficial impact of mica powder, furthering its position as a valued component in material innovation. For those invested in sustainable practices, mica powder offers a noteworthy ecological footprint—a renewable and abundant resource that aligns seamlessly with green engineering principles, reducing reliance on synthetic additives. However, the key to unlocking the full potential of mica powder lies in the precision with which it is handled and incorporated into plastic blends. Expert processors understand that the uniform distribution of mica particles is imperative to avoid the compromise of structural integrity. This detail-oriented approach is born from years in the field, where the selection of milling techniques and binder systems play critical roles. This nuanced expertise isn't just reserved for scientists and chemists but extends to manufacturers and product developers, as they must pragmatically balance formulation techniques with cost efficiency and production scalability. The technical know-how and cumulative industry wisdom enhance the reliability and trustworthiness of mica-enhanced plastics, leading to trust among consumers who demand performance and longevity from plastic products. In conclusion, mica powder’s contribution to the plastic industry illustrates a confluence of aesthetic and mechanical triumphs. Through years of dedicated research and practical application, it stands as a testament to material evolution that meets the modern demands of efficiency, beauty, and sustainability. This synthesis of trusted experience and proven scientific authority establishes mica powder as indispensable in the ongoing narrative of advanced manufacturing solutions.

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories