Jan . 09, 2025 12:09

Back to list

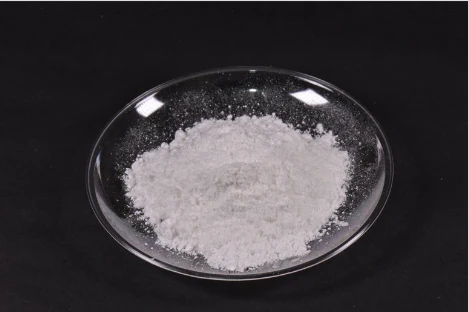

large mica flakes

In the world of advanced materials, mica stands out due to its indispensable properties like thermal resistance, elasticity, and transparency. These attributes make it a critical component in various industrial applications ranging from electronics to construction. The mica manufacturing industry comprises a diverse array of players, each contributing unique expertise and innovations, which are crucial to understanding for stakeholders across these sectors.

Quality assurance remains a cornerstone of the mica manufacturing process. Esteemed companies adhere to international quality standards like ISO 9001, guaranteeing that their products meet global benchmarks. Their compliance not only reflects a commitment to excellence but also instills confidence among consumers and industrial clients, fostering long-term partnerships and trust. Furthermore, mica manufacturers invest in research and development to explore new applications and improve existing products. Innovative R&D teams work on enhancing mica's properties to better serve emerging technologies such as 5G, electric vehicles, and renewable energy systems. This proactive approach ensures that they remain ahead of market demands and competitive pressures. Manufacturers also play a pivotal role in the global supply chain. With supply chain transparency becoming increasingly important, leading mica companies often engage in responsible sourcing practices, ensuring that their raw materials are procured ethically and sustainably. This not only mitigates risks associated with environmental and social governance but also strengthens the overall supply chain integrity. A comprehensive understanding of the mica manufacturing landscape reflects their indispensable position as both suppliers and innovators. Companies that leverage their deep expertise, commitment to quality, and strategic innovation set themselves apart as authoritative leaders in the market. In summary, mica manufacturers are vital in delivering high-performance materials crucial for several industries. Their authoritative command over technical processes, commitment to quality, and sustainable practices not only ensure their products meet rigorous demands but also position them as trusted partners worldwide. As industries evolve, these manufacturers are expected to continue spearheading pioneering efforts that drive advancements and sustainability in material sciences.

Quality assurance remains a cornerstone of the mica manufacturing process. Esteemed companies adhere to international quality standards like ISO 9001, guaranteeing that their products meet global benchmarks. Their compliance not only reflects a commitment to excellence but also instills confidence among consumers and industrial clients, fostering long-term partnerships and trust. Furthermore, mica manufacturers invest in research and development to explore new applications and improve existing products. Innovative R&D teams work on enhancing mica's properties to better serve emerging technologies such as 5G, electric vehicles, and renewable energy systems. This proactive approach ensures that they remain ahead of market demands and competitive pressures. Manufacturers also play a pivotal role in the global supply chain. With supply chain transparency becoming increasingly important, leading mica companies often engage in responsible sourcing practices, ensuring that their raw materials are procured ethically and sustainably. This not only mitigates risks associated with environmental and social governance but also strengthens the overall supply chain integrity. A comprehensive understanding of the mica manufacturing landscape reflects their indispensable position as both suppliers and innovators. Companies that leverage their deep expertise, commitment to quality, and strategic innovation set themselves apart as authoritative leaders in the market. In summary, mica manufacturers are vital in delivering high-performance materials crucial for several industries. Their authoritative command over technical processes, commitment to quality, and sustainable practices not only ensure their products meet rigorous demands but also position them as trusted partners worldwide. As industries evolve, these manufacturers are expected to continue spearheading pioneering efforts that drive advancements and sustainability in material sciences.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories