Jan . 09, 2025 11:45

Back to list

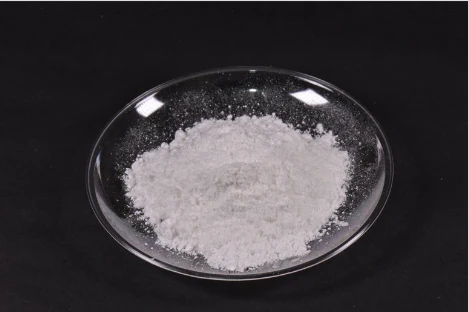

D-5 MICA

Mica manufacturers have carved an essential niche in the global market, serving as the backbone of numerous industries due to mica’s unique characteristics. These manufacturers are not merely producers of raw materials but are pioneers of technological advancement and sustainability. With an ever-growing demand for mica in electronic devices, construction, and automotive industries, selecting the right manufacturer is crucial.

The shift towards sustainable practices has seen many forward-thinking mica manufacturers investing in green technologies. This move includes the development of techniques to safely and efficiently mine mica, reducing environmental footprints. Furthermore, these manufacturers are adopting closed-loop systems that recycle water and other resources, minimizing waste production. This commitment to the environment not only enhances the manufacturer’s reputation but also aligns with the growing consumer demand for sustainable products. Customer experience is paramount in the product lifecycle. Leading manufacturers offer comprehensive support, from initial inquiries to post-purchase assistance. Offering a range of custom mica products tailored to specific industry needs ensures that clients can rely on solutions that fit their operational requirements seamlessly. The ability to provide bespoke solutions is a testament to the manufacturer’s expertise and commitment to excellence. Additionally, pioneering companies in the mica manufacturing sector have embraced digital transformation. Integrating artificial intelligence and machine learning into their processes allows for enhanced quality control, predictive maintenance, and increased operational efficiency. Customers benefit from these innovations through better product predictability and accelerated order fulfilment times. In conclusion, the landscape of mica manufacturing is defined by expertise, innovation, and adherence to sustainability. Choosing the right mica manufacturer is not solely about product availability but involves a comprehensive evaluation of the manufacturer’s commitment to quality, ethical practices, and customer satisfaction. In a market saturated with choices, those manufacturers who rise to meet these standards distinguish themselves as leaders, offering not just products but partnerships marked by reliability and mutual growth potential.

The shift towards sustainable practices has seen many forward-thinking mica manufacturers investing in green technologies. This move includes the development of techniques to safely and efficiently mine mica, reducing environmental footprints. Furthermore, these manufacturers are adopting closed-loop systems that recycle water and other resources, minimizing waste production. This commitment to the environment not only enhances the manufacturer’s reputation but also aligns with the growing consumer demand for sustainable products. Customer experience is paramount in the product lifecycle. Leading manufacturers offer comprehensive support, from initial inquiries to post-purchase assistance. Offering a range of custom mica products tailored to specific industry needs ensures that clients can rely on solutions that fit their operational requirements seamlessly. The ability to provide bespoke solutions is a testament to the manufacturer’s expertise and commitment to excellence. Additionally, pioneering companies in the mica manufacturing sector have embraced digital transformation. Integrating artificial intelligence and machine learning into their processes allows for enhanced quality control, predictive maintenance, and increased operational efficiency. Customers benefit from these innovations through better product predictability and accelerated order fulfilment times. In conclusion, the landscape of mica manufacturing is defined by expertise, innovation, and adherence to sustainability. Choosing the right mica manufacturer is not solely about product availability but involves a comprehensive evaluation of the manufacturer’s commitment to quality, ethical practices, and customer satisfaction. In a market saturated with choices, those manufacturers who rise to meet these standards distinguish themselves as leaders, offering not just products but partnerships marked by reliability and mutual growth potential.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories