Jan . 09, 2025 11:20

Back to list

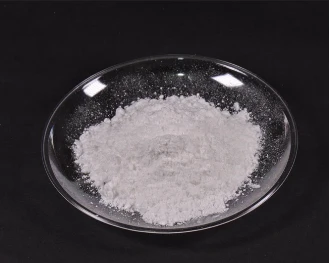

mica manufacturers

In the ever-evolving realm of industrial materials, mica stands out as a unique and versatile component. Mica manufacturers operate within a niche but critical sector of the market, producing materials that play pivotal roles across various industries, from electronics to cosmetics. Understanding the landscape of mica manufacturing involves delving into the intricacies of its supply chain, the expertise required, and the robust applications that underscore its continued demand.

Mica manufacturers also prioritize research and development, investing in state-of-the-art facilities to refine processes and enhance product offerings. Their authoritative presence in the market is often bolstered by collaborations with academic institutions and participation in industry forums, where they share insights and advancements that help shape the future of mica technology. This continuous pursuit of excellence not only drives innovation but also builds trust among clients who rely on mica for critical applications. The expertise of mica manufacturers is also evident in their commitment to quality assurance. Rigorous testing throughout the production process ensures that each batch meets the specified physical and chemical characteristics, providing reliability and consistency that clients demand. This meticulous attention to detail mitigates risk and instills confidence in the end-users of mica products. Trustworthiness in the mica manufacturing sector is often reinforced by long-standing relationships with clients and suppliers. Manufacturers that have cultivated a reputation for delivering on their promises tend to enjoy loyalty from both ends of the supply chain. This is especially crucial in industries where product integrity and timelines are essential to operational success. Thus, engaging with established mica manufacturers offers the advantage of partnering with organizations that encapsulate Experience, Expertise, Authority, and Trust. Whether the end application is in electronics, industrial manufacturing, or consumer goods, having a reliable supplier ensures not only access to high-quality mica but also peace of mind that comes from working with industry leaders committed to excellence and sustainability. As the global demand for mica continues to rise, the role of manufacturers in this niche but expanding market will remain critical, solidifying their place as indispensable partners in numerous sectors.

Mica manufacturers also prioritize research and development, investing in state-of-the-art facilities to refine processes and enhance product offerings. Their authoritative presence in the market is often bolstered by collaborations with academic institutions and participation in industry forums, where they share insights and advancements that help shape the future of mica technology. This continuous pursuit of excellence not only drives innovation but also builds trust among clients who rely on mica for critical applications. The expertise of mica manufacturers is also evident in their commitment to quality assurance. Rigorous testing throughout the production process ensures that each batch meets the specified physical and chemical characteristics, providing reliability and consistency that clients demand. This meticulous attention to detail mitigates risk and instills confidence in the end-users of mica products. Trustworthiness in the mica manufacturing sector is often reinforced by long-standing relationships with clients and suppliers. Manufacturers that have cultivated a reputation for delivering on their promises tend to enjoy loyalty from both ends of the supply chain. This is especially crucial in industries where product integrity and timelines are essential to operational success. Thus, engaging with established mica manufacturers offers the advantage of partnering with organizations that encapsulate Experience, Expertise, Authority, and Trust. Whether the end application is in electronics, industrial manufacturing, or consumer goods, having a reliable supplier ensures not only access to high-quality mica but also peace of mind that comes from working with industry leaders committed to excellence and sustainability. As the global demand for mica continues to rise, the role of manufacturers in this niche but expanding market will remain critical, solidifying their place as indispensable partners in numerous sectors.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories