Feb . 02, 2025 03:23

Back to list

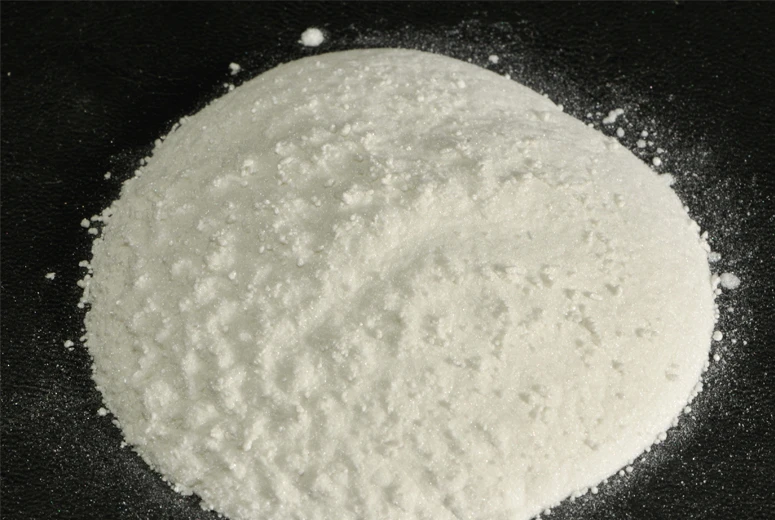

white mica powder for resin

Mica flakes in resin present a fascinating blend of aesthetic appeal and functional benefits, making them a popular choice in various industries. These sparkling particles, when embedded in resin, create a dynamic, multi-dimensional look that captivates the eye and enhances the intrinsic value of the finished product. Through exploring their applications, production processes, and benefits, we can appreciate how they have become an indispensable component in realms ranging from art to construction.

For those interested in DIY projects, using mica flakes in resin can be a rewarding endeavor. Beginners and seasoned hobbyists alike appreciate the versatility they offer. By experimenting with different hues and flake sizes, creators can find endless possibilities to express their vision. However, a proper understanding of resin curing times and safety protocols is essential. Protective gear and a well-ventilated workspace are non-negotiable, ensuring safety and optimal results. The versatility of mica-flake-infused resin extends beyond aesthetics and function into aspects of design and innovation. Engineers and designers continually explore its potential in creating products with enhanced mechanical and electrical properties. For example, researchers are investigating the potential for mica to enhance electromagnetic shielding when incorporated into composite materials. This could prove revolutionary in electronics, where managing electromagnetic interference is critical. Trust in the quality of mica flakes in resin products is reinforced by the rigorous testing and quality assurance measures employed throughout the manufacturing process. Industry standards dictate stringent quality controls, ensuring that the mica used is free from impurities that could impact the resin’s appearance or performance. Leading suppliers often provide comprehensive technical data sheets, enabling informed decision-making for both professionals and consumers alike. In conclusion, mica flakes in resin offer a compelling combination of beauty, durability, and innovation. From revitalizing artistic endeavors to advancing construction techniques, they have proven their worth across multiple disciplines. By prioritizing quality and safety, and remaining attuned to emerging trends and technologies, stakeholders in this space continue to expand the horizons of what is possible, reinforcing mica’s role as a cornerstone material in both creative and industrial applications. Whether adorning a piece of art or strengthening a structural component, mica flakes, seamlessly integrated into resin, enrich our world with their shimmering presence.

For those interested in DIY projects, using mica flakes in resin can be a rewarding endeavor. Beginners and seasoned hobbyists alike appreciate the versatility they offer. By experimenting with different hues and flake sizes, creators can find endless possibilities to express their vision. However, a proper understanding of resin curing times and safety protocols is essential. Protective gear and a well-ventilated workspace are non-negotiable, ensuring safety and optimal results. The versatility of mica-flake-infused resin extends beyond aesthetics and function into aspects of design and innovation. Engineers and designers continually explore its potential in creating products with enhanced mechanical and electrical properties. For example, researchers are investigating the potential for mica to enhance electromagnetic shielding when incorporated into composite materials. This could prove revolutionary in electronics, where managing electromagnetic interference is critical. Trust in the quality of mica flakes in resin products is reinforced by the rigorous testing and quality assurance measures employed throughout the manufacturing process. Industry standards dictate stringent quality controls, ensuring that the mica used is free from impurities that could impact the resin’s appearance or performance. Leading suppliers often provide comprehensive technical data sheets, enabling informed decision-making for both professionals and consumers alike. In conclusion, mica flakes in resin offer a compelling combination of beauty, durability, and innovation. From revitalizing artistic endeavors to advancing construction techniques, they have proven their worth across multiple disciplines. By prioritizing quality and safety, and remaining attuned to emerging trends and technologies, stakeholders in this space continue to expand the horizons of what is possible, reinforcing mica’s role as a cornerstone material in both creative and industrial applications. Whether adorning a piece of art or strengthening a structural component, mica flakes, seamlessly integrated into resin, enrich our world with their shimmering presence.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories