Jan . 09, 2025 11:40

Back to list

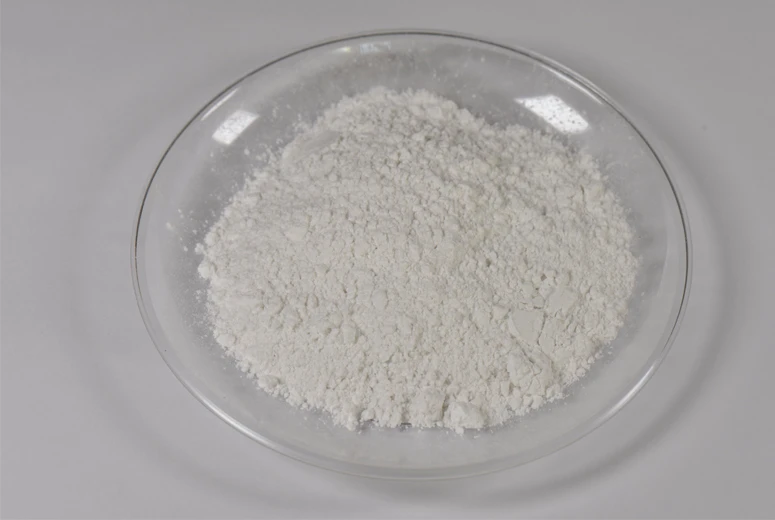

large mica flakes

Navigating the world of mica manufacturing reveals an intricate landscape marked by excellence, innovation, and reliability. Mica, a group of silicate minerals renowned for their heat resistance, electrical insulation, and brilliant reflecting properties, serves as a cornerstone for numerous industrial applications ranging from electronics to cosmetics and construction materials. For businesses seeking quality mica materials, understanding the intricacies of sourcing, processing, and application is paramount.

The journey from raw mica to finished product must be underscored by authoritativeness. Globally recognized mica manufacturers often possess certifications and accreditations that attest to their commitment to quality and environmental sustainability. ISO certifications, for instance, verify adherence to international standards, reassuring clients of the manufacturing process's reliability. Additionally, these factories are often vocal participants in industrial forums and committees, contributing to the development of industry guidelines and innovations that shape the future of mica usage. Trustworthiness in a mica factory is derived not only from product quality but also from transparent and ethical business practices. Leading manufacturers ensure that their operations are environmentally responsible, implementing sustainable mining practices and minimizing waste during production. They are equally committed to ethical labor practices, ensuring that all workers enjoy safe working conditions and fair wages. Their commitment to corporate social responsibility extends beyond production, often involving community development initiatives that support the regions where they operate. Selecting a mica factory that embodies these values ensures that businesses can trust in the materials they are sourcing. The quality, purity, and performance of mica products—from tapes, sheets, and flakes to powders and pigments—play a critical role in the integrity of the finished goods in which they are utilized. Whether it is insulating electrical components, enhancing the aesthetics of cosmetics, or reinforcing building materials, the right mica product can make all the difference. By understanding the manufacturing process and choosing an operator that prioritizes experience, expertise, authoritativeness, and trustworthiness, companies can ensure that they are investing in materials that enhance their own product offerings and uphold their brand's promise of quality and reliability. With this knowledge, businesses are better positioned to make informed decisions that drive success in their respective markets.

The journey from raw mica to finished product must be underscored by authoritativeness. Globally recognized mica manufacturers often possess certifications and accreditations that attest to their commitment to quality and environmental sustainability. ISO certifications, for instance, verify adherence to international standards, reassuring clients of the manufacturing process's reliability. Additionally, these factories are often vocal participants in industrial forums and committees, contributing to the development of industry guidelines and innovations that shape the future of mica usage. Trustworthiness in a mica factory is derived not only from product quality but also from transparent and ethical business practices. Leading manufacturers ensure that their operations are environmentally responsible, implementing sustainable mining practices and minimizing waste during production. They are equally committed to ethical labor practices, ensuring that all workers enjoy safe working conditions and fair wages. Their commitment to corporate social responsibility extends beyond production, often involving community development initiatives that support the regions where they operate. Selecting a mica factory that embodies these values ensures that businesses can trust in the materials they are sourcing. The quality, purity, and performance of mica products—from tapes, sheets, and flakes to powders and pigments—play a critical role in the integrity of the finished goods in which they are utilized. Whether it is insulating electrical components, enhancing the aesthetics of cosmetics, or reinforcing building materials, the right mica product can make all the difference. By understanding the manufacturing process and choosing an operator that prioritizes experience, expertise, authoritativeness, and trustworthiness, companies can ensure that they are investing in materials that enhance their own product offerings and uphold their brand's promise of quality and reliability. With this knowledge, businesses are better positioned to make informed decisions that drive success in their respective markets.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories