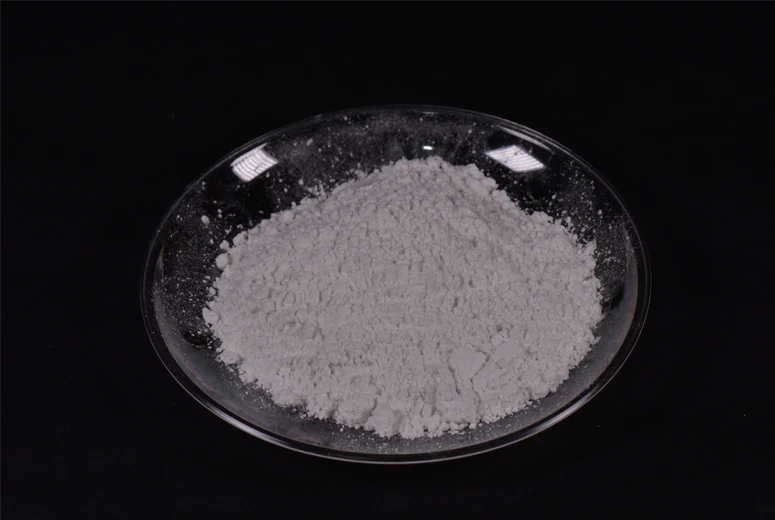

D-5 MICA

In the heart of the industrial sector, mica factories symbolize a blend of traditional craftsmanship and modern production efficiencies. These factories are pivotal in producing mica products used in a myriad of applications ranging from electronics to insulation materials. The journey of mica from a raw mineral to a finished product is a testament to precision, expertise, and the relentless pursuit of quality.

Mica factories are hubs of meticulous operations, where the process begins with the careful extraction of mica from mines. It is a labor-intensive stage, requiring skilled workers who can identify, sort, and handle this delicate mineral without compromising its inherent properties. The expertise of these workers is foundational; their hands-on experience ensures that only the highest quality mica is selected for further processing.

Once the raw mica reaches the factory floor, it undergoes several stages of refinement, each executed with surgical precision. The slicing of mica sheets is a critical process that demands both state-of-the-art machinery and the keen oversight of trained technicians. These technicians are not just operators but custodians of quality, ensuring that each sheet meets stringent industrial standards. Their competence establishes the factory’s reputation for excellence, as consistency in product quality is non-negotiable in competitive markets.

In these factories, technological advancement coexists with traditional practices. Automation plays a significant role in enhancing efficiency and minimizing human error, yet the human touch remains indispensable. The calibration and programming of machinery are the realms of engineers who bring their authoritative knowledge to bear, bridging the gap between mechanical processes and material science.

Furthermore, the environmental credibility of mica factories is increasingly under scrutiny. Sustainable practices are integrated into the production cycle, from reducing waste to implementing recycling protocols. These efforts not only improve the trustworthiness of the factory among environmentally conscious consumers but also align with global standards for ecological responsibility.

mica factory

The mica factories also extend their influence beyond production. They serve as knowledge centers for new applications and innovations involving mica. Research and Development (R&D) teams within these facilities are continuously exploring novel uses for mica, collaborating with academic institutions and industry experts. This proactive approach positions them as thought leaders in the sector, driving advancements in areas such as high-tech composites and green technology applications.

At the operational level, maintaining transparency and accountability further bolsters a factory’s standing in the market. From the procurement of raw mica to the delivery of finished products, every step is meticulously documented and reported. Industry certifications and quality assurance protocols provide an additional layer of trust, reassuring clients and partners of the factory’s commitment to high standards.

The credibility of a mica factory is also reflected in its corporate social responsibility initiatives. By supporting local communities and ensuring fair labor practices, these factories foster an ethical production environment. This commitment to social equity enhances their appeal to global partners who value sustainable and human-centric business practices.

In conclusion, mica factories are not mere production units; they are institutions of craftsmanship and industrial expertise. They offer a unique blend of experience, authority, and trustworthiness, ensuring that every mica product leaving their premises not only meets but exceeds market expectations. These factories continue to innovate and adapt, standing as pillars of excellence in an ever-evolving industrial landscape. Through a steadfast commitment to quality and sustainability, they secure their position as leaders within the mica production industry.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories