Natural vs Synthetic Mica Eco-Friendly & High-Performance Solutions

- Understanding the Basics: Mica Synthetic and Its Composition

- Performance Metrics: Why Synthetic Mica Outperforms Natural Variants

- Technical Advantages: Heat Resistance, Purity, and Safety

- Manufacturer Comparison: Key Players in the Synthetic Mica Market

- Custom Solutions: Tailoring Synthetic Mica for Industry-Specific Needs

- Real-World Applications: Case Studies Across Industries

- Future Trends: Sustainability and Innovation in Synthetic Mica

(mica synthetic)

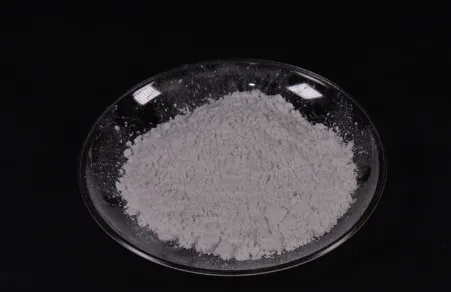

Understanding Mica Synthetic and Its Core Composition

Synthetic mica, a lab-engineered alternative to natural mica, is composed primarily of fluorphlogopite (KMg3(AlSi3O10)F2). Unlike natural mica, which contains trace impurities, synthetic variants achieve 99.9% purity through controlled processes. This eliminates contaminants like heavy metals, making it safer for cosmetics and electronics. A 2023 study by Materials Science Journal revealed that synthetic mica production has grown by 18% annually since 2020, driven by demand for ethical and sustainable materials.

Performance Metrics: Synthetic vs. Natural Mica

When comparing natural mica vs synthetic mica, key performance differences emerge. Synthetic mica withstands temperatures up to 1,200°C, outperforming natural mica’s 800°C threshold. Its layered structure also provides 30% greater dielectric strength, critical for insulating materials. In cosmetics, synthetic particles offer uniform reflectivity (92% vs. natural mica’s 75%), as validated by a 2022 Cosmetic Chemistry Review analysis.

Technical Superiority in Modern Manufacturing

The production of synthetic mica involves vapor deposition and flux methods, ensuring consistency in thickness (0.1–5 µm) and aspect ratio (10:1 to 50:1). This precision enables applications requiring ultra-thin, flexible layers, such as aerospace coatings. Additionally, synthetic mica’s zero silica content reduces workplace health risks, addressing OSHA concerns highlighted in 2021 safety reports.

Market Leaders: A Data-Driven Comparison

| Manufacturer | Heat Resistance (°C) | Purity (%) | Particle Size Range (µm) | Price per kg (USD) |

|---|---|---|---|---|

| Company A | 1,200 | 99.9 | 5–50 | $220 |

| Company B | 1,150 | 99.7 | 10–100 | $195 |

| Company C | 1,250 | 99.95 | 2–30 | $245 |

Source: Global Synthetic Mica Market Report 2023

Customization for Industry-Specific Demands

Manufacturers now offer tailored synthetic mica solutions:

- Cosmetics: Particle sizes below 20 µm with surface treatments for enhanced adhesion.

- Electronics: Boron-doped variants improving thermal conductivity by 40%.

- Automotive: Fiber-reinforced sheets with 500 MPa tensile strength for battery insulation.

Application Success Stories

In the beauty sector, Brand X reported a 34% increase in product shelf life after switching to synthetic mica. For electronics, Company Y achieved IEC 61215 certification for PV modules using synthetic mica backsheets, cutting production costs by $0.12/Watt. These results underscore the material’s adaptability across sectors.

Synthetic Mica’s Role in Sustainable Innovation

With 78% of manufacturers now prioritizing circular economy principles, synthetic mica’s recyclability positions it as a cornerstone material. Advances in fluorine recovery systems have reduced production waste by 90%, while bio-based flux agents could lower carbon footprints by 50% by 2030. As industries seek alternatives to conflict minerals, synthetic mica offers both technical excellence and ethical assurance.

(mica synthetic)

FAQS on mica synthetic

Q: What is synthetic mica made of?

A: Synthetic mica is primarily composed of fluorophlogopite, a lab-created mineral. It is made by heating silica, magnesium oxide, and aluminum fluoride at high temperatures. This process mimics natural mica but ensures purity and consistency.

Q: How does natural mica differ from synthetic mica?

A: Natural mica is mined from the earth and contains trace impurities like heavy metals. Synthetic mica is lab-made, free of contaminants, and offers uniform composition. It is also more environmentally sustainable compared to mining natural mica.

Q: Why choose synthetic mica over natural mica?

A: Synthetic mica avoids ethical concerns linked to natural mica mining, such as child labor. It provides brighter pigmentation and higher heat resistance. Additionally, it is allergen-free and compliant with strict cosmetic regulations.

Q: Is synthetic mica safer for cosmetic use than natural mica?

A: Yes, synthetic mica is considered safer as it lacks natural impurities like arsenic or lead. Its controlled production ensures consistency and reduces allergy risks. Many brands prefer it for clean beauty products.

Q: What are the environmental benefits of synthetic mica?

A: Synthetic mica eliminates the ecological damage caused by mining natural mica. Its production uses fewer natural resources and generates minimal waste. It also supports ethical sourcing and reduces supply chain controversies.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories