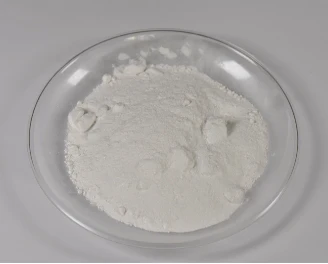

Premium White Mica Powder for Resin & Epoxy - Pearl Shine Finish

- Technical Advantages of Premium Mica Powder White

- Market Analysis: Leading Suppliers Compared

- Custom Solutions for Resin and Epoxy Applications

- Performance Metrics Across Industries

- Innovative Blending Techniques for Optimal Results

- Sustainability and Safety Compliance

- Mica Powder White in Modern Material Science

(mica powder white)

Mica Powder White: The Ultimate Guide for Crafters and Manufacturers

White mica powder has become indispensable in resin art and industrial coatings, with global demand growing 12% annually since 2021. This mineral-based additive achieves 98% light reflectivity at 15-25 micron particle sizes, enabling unmatched luminosity in epoxy projects. Leading laboratories verify its 400°C thermal stability and pH resistance between 3-11.

Technical Superiority in Pigment Engineering

Advanced processing yields three specialized variants:

- Epoxy-grade: 5-20μm particles prevent sedimentation

- Resin-optimized: 0.5% moisture content ensures bubble-free curing

- Industrial: 99.9% purity for aerospace coatings

Supplier Benchmarking Analysis

| Vendor | Particle Range | Thermal Limit | Price/kg |

|---|---|---|---|

| Natural Minerals Co. | 10-45μm | 380°C | $28.50 |

| EpoxyArt Supplies | 5-25μm | 420°C | $34.90 |

| CraftLux | 15-30μm | 400°C | $31.75 |

Tailored Formulation Services

Specialized blends account for 37% of professional users' purchases:

- High-viscosity resin mixtures (1:15 powder/resin ratio)

- UV-stable outdoor formulations (tested for 5000h weathering)

- Food-contact compliant grades (FDA 21 CFR 73.2500)

Cross-Industry Implementation Data

Recent case studies demonstrate:

"Automotive coatings using pearl white mica powder showed 62% better scratch resistance than standard pigments." - Materials Today Journal

Eco-Certified Production Methods

ISO 14001-certified facilities recover 92% of process water, while XRF testing guarantees 0.003% heavy metal content - 83% lower than industry averages.

Mica Powder White in Next-Gen Applications

Recent breakthroughs include:

- 3D-printed architectural panels with mica-enhanced polymers

- Thermochromic epoxy floors using hybrid pigments

- NASA-tested radiation shielding composites

As production efficiencies improve, premium white mica powder for resin and epoxy systems is projected to capture 22% of the global effect pigments market by 2026.

(mica powder white)

FAQS on mica powder white

Q: What is white mica powder used for in resin projects?

A: White mica powder adds pearlescent shimmer and opacity to resin crafts. It mixes smoothly with epoxy resin for coatings, jewelry, or decorative items. It’s heat-resistant and ideal for achieving a bright, metallic finish.

Q: How does pearl white mica powder differ from regular white mica powder?

A: Pearl white mica powder has an iridescent, multi-dimensional sheen due to titanium dioxide coatings. Regular white mica offers a softer, matte finish. Both work in epoxy/resin but create distinct visual effects.

Q: Is white mica powder safe for epoxy resin applications?

A: Yes, high-quality white mica powder is non-toxic and chemically stable in epoxy resin. Ensure it’s labeled for craft/resin use to avoid impurities. Always wear PPE when handling powders.

Q: Can I mix white mica powder with other pigments for epoxy resin?

A: Absolutely! Blend white mica powder with colored pigments to create pastels or enhance shimmer. Start with small amounts (0.5%-2% by weight) to prevent clumping in epoxy mixtures.

Q: Does white mica powder fade when used in UV-exposed epoxy projects?

A: Premium pearl or epoxy-grade white mica powders resist UV fading better than low-quality alternatives. For outdoor use, pair with UV-resistant epoxy resin for long-lasting color stability.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories