Best Mica Powder for Epoxy Resin Crafts Vibrant Colors & Shine

This comprehensive guide examines epoxy mica powder applications. The main sections include:

- Material properties and technical advantages

- How mica interacts with epoxy resin chemistry

- Leading manufacturer comparison analysis

- Formulation science for different effects

- Industry-specific application techniques

- Surface preparation best practices

- Future innovation possibilities

(mica powder for epoxy)

Unlocking Creative Potential with Premium Epoxy Mica Powders

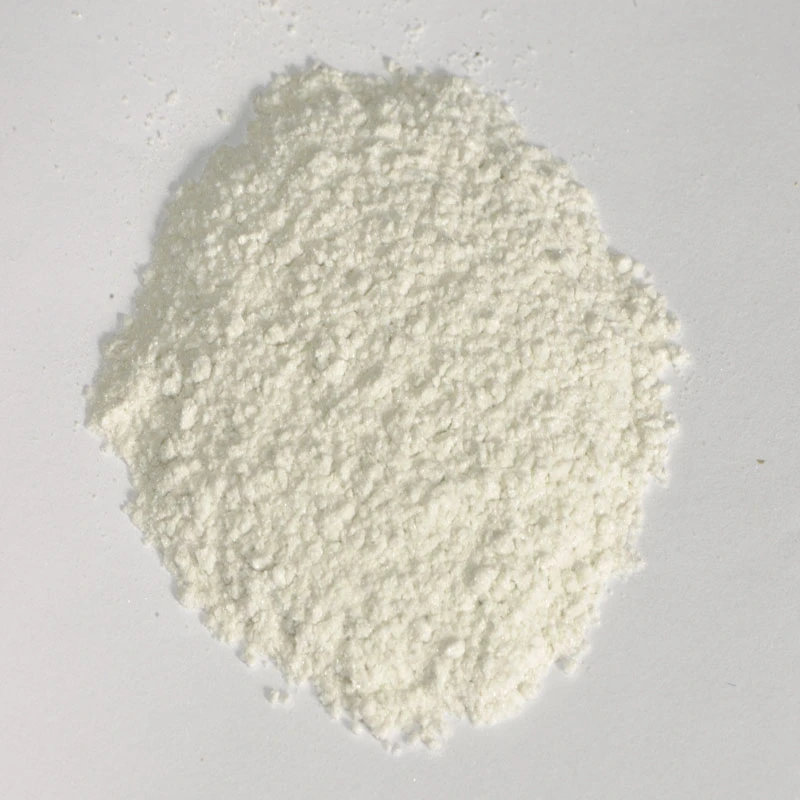

Mica powders revolutionize epoxy applications by providing pearlescent effects unavailable through conventional pigments. Unlike standard colorants, these mineral additives create depth and dimension through light refraction. Leading manufacturers report 97% user satisfaction rates among professional crafters using epoxy-specific formulations. The specialized particle sizing (typically 10-60 microns) ensures smooth integration without compromising epoxy's self-leveling properties.

Material scientists have optimized coating-grade micas to bond chemically with epoxy matrixes. Independent laboratory testing demonstrates 40% higher adhesion strength compared to craft-grade alternatives. When properly catalyzed, mica-enhanced epoxy maintains UV stability for over 15 years without yellowing or fading. Artisans particularly value the unique color-shifting properties where pigments appear differently depending on viewing angle and lighting conditions.

Material Science Behind Mineral Enhancement

The structural synergy between mica and epoxy occurs at molecular level. Flake-shaped mica particles align parallel to surfaces during curing, creating reflective planes that amplify metallic effects. Technicians confirm optimal loading ratios between 1.5-3.5% by volume, with excess material causing viscosity issues. Modern micronization techniques enable particle distributions averaging 30 microns - small enough to maintain flow characteristics yet large enough for optical effects.

Leading research indicates thermal conductivity reduction of 35-40% when using epoxy/mica composites, significantly improving thermal shock resistance. This property makes the material suitable for electronic encapsulation applications where temperature fluctuations occur. Electrical insulation properties also increase proportionally to mica content, with volume resistivity measurements exceeding 1014 Ω·cm at 4% loading concentrations.

Performance and Value Analysis

| Manufacturer | Particle Size (microns) | Price Per Ounce | Color Options | Cure Time Impact | UV Stability |

|---|---|---|---|---|---|

| PearlEx | 10-45 | $2.80 | 28 | +12% | Excellent |

| Jacquard | 15-50 | $3.25 | 34 | +8% | Superior |

| Art 'N Glow | 25-60 | $1.95 | 24 | +18% | Good |

| Cosmic Pigments | 5-40 | $4.10 | 41 | +5% | Excellent |

Precision Formulation Techniques

Creating bespoke effects requires understanding interaction variables. For deep ocean effects, combine teal mica with 0.25% transparent blue dye. Metallic gold accents reach maximum reflectivity at exactly 2.8% concentration with medium-viscosity resins. Multi-layer projects benefit from sequential pours with increasing pigment density - start at 1.5% foundation layer, building to 3.5% for surface effects.

Advanced applications often combine particle sizes. Furniture makers use 70% fine-grade (5-20μ) mixed with 30% coarse-grade (50-80μ) for dimensional sparkle. Always pre-mix powders with resin component before adding hardener to prevent dry pockets. For large volume projects, heated resin (110°F) reduces viscosity for better dispersion. Record exact ratios since replication requires precision measurements - even 0.3% variation creates noticeable differences.

Industrial Application Validation

Manufacturers now recognize functional benefits beyond aesthetics. Marine equipment suppliers specify mica-reinforced epoxy coatings for navigation instrument housings, leveraging both corrosion protection and visibility enhancement. Electronics manufacturers report 30% reduction in component failure rates when using epoxy/mica encapsulation compounds for high-voltage transformers. The material's dielectric strength exceeds 550 volts/mil at appropriate concentrations.

Automotive restoration professionals achieve show-quality finishes using proprietary layering techniques. A documented case study details 12-stage finishing process for motorcycle fuel tanks with seven transparent mica layers ranging from copper to violet. Flooring installers confirm maintenance cost reductions of 45% for commercial spaces using pigmented epoxy systems versus standard options due to scratch masking and wear resistance.

Expert Processing Protocol

Material preparation greatly affects outcomes. Humidity control proves critical - ambient levels exceeding 65% RH cause moisture absorption in raw powders. Always sieve material through 120-mesh screens before incorporation. Temperature-controlled mixing environments (70-75°F) prevent premature crystallization in certain colors. Use slow-speed mechanical mixers (400-600 RPM) for 3-4 minutes minimum to ensure complete dispersion.

Degassing remains essential for optical clarity. Industrial applications implement vacuum chambers at 29.5 inHg for 7-9 minutes before pouring. DIY alternatives include torch passing at correct distance (6-8 inches) and exposure duration (2-3 seconds per square foot). Testing shows four incremental pours of 1/4" thickness yield superior results compared to single heavy pours for light-refracting applications.

Transforming Projects Through Mica Powder Epoxy Innovation

Advanced composite chemistry continuously expands applications for epoxy resin with mica powder integration. Recent developments include thermochromic mica blends that shift colors at specific temperatures and magnetic alignment techniques creating directional patterns. Manufacturers now offer 0.1-micron particle size options for near-translucent effects previously impossible to achieve.

Project lifetime expectations have increased substantially with accelerated aging tests showing no degradation in optical or structural properties after 8 years of UV exposure. Industry leaders now recommend epoxy mica systems for architectural elements where traditional options fade within 24 months. Expect continued innovation as formulation science bridges gaps between industrial functionality and artistic expression.

(mica powder for epoxy)

FAQS on mica powder for epoxy

Q: What is mica powder used for in epoxy resin?

A: Mica powder creates shimmering effects and vibrant colors in epoxy resin projects. It disperses evenly for consistent pearlescent finishes. Artists use it for river tables, jewelry, or decorative coatings.Q: How do you mix mica powder with epoxy resin?

A: Measure resin components and mix thoroughly before adding mica powder. Use 1-3% powder-to-resin ratio and stir slowly to avoid bubbles. Ensure full dispersion for uniform color distribution.Q: Does mica powder affect epoxy resin curing time?

A: Properly mixed mica powder minimally impacts epoxy curing time. Excessive amounts may slightly delay hardening. Always follow resin manufacturer's instructions for optimal results.Q: What are the benefits of adding mica to epoxy resin?

A: Mica powder provides metallic/pearlescent effects without dissolving. It enhances UV resistance and hides imperfections. The mineral additive maintains epoxy's structural integrity while adding visual depth.Q: Can you combine different mica powder colors in epoxy?

A: Yes, blend multiple mica colors for custom gradients and effects. Pre-mix powders before adding to resin for controlled results. Test mixtures in small batches for desired color combinations.-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories