Mar . 03, 2025 12:22

Back to list

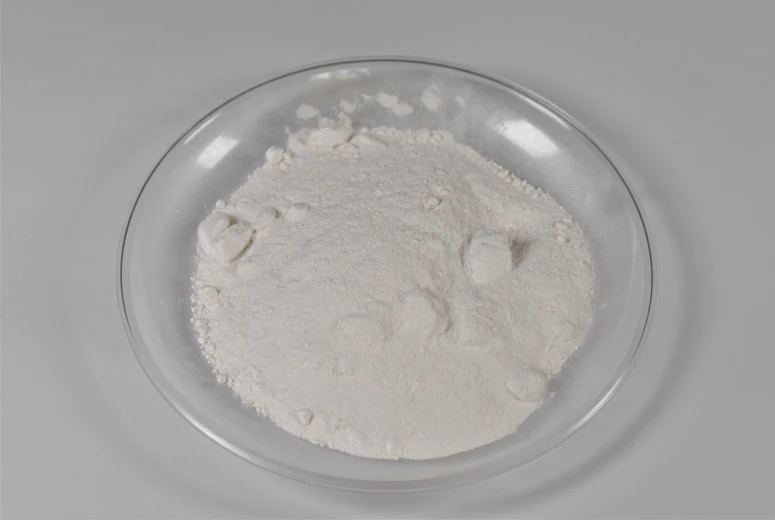

how is mica powder made

Mica powder is an integral component in a myriad of products, ranging from cosmetics to paints. The journey of mica powder from raw mineral to its powdered form is intricate, marked by a series of expert processes that demand both experience and precision.

Grinding is where mica takes on its powdered form. This phase requires specialized equipment capable of achieving the delicate fineness needed for various applications. The fine powder must meet specific parameters set by industries such as cosmetics, which demand ultra-fine, smooth mica for its light-reflecting properties. The grinding mills used can be configured to follow precise technical adjustments, balancing mechanical force to achieve the desired consistency without diminishing the material's quality. Through this process, technical prowess and meticulous attention to detail shine through, reflecting an authoritative understanding of mica's role across different mediums. Quality control plays a vital part in the process. With the help of sophisticated technology and skilled inspectors, every batch of mica powder is rigorously tested for uniformity, safety, and compliance with industry standards. Regular testing against international benchmarks ensures trustworthiness and safety in end products. Sustainability is increasingly crucial in today's production processes. Ethical sourcing and environmentally friendly practices are now integral to manufacturing mica powder. Industry leaders are committed to reducing the environmental impact through energy-efficient technologies and responsible mining practices, providing transparency in sourcing and production. This ethical approach serves to enhance both the authority and trustworthiness of mica powder producers on the global stage. In conclusion, the production of mica powder is a multifaceted process underpinned by a blend of skilled craftsmanship, technological innovation, and rigorous quality assurance. It stands as a model of expertise and trustworthiness in the industry, ensuring that whether the mica ends up in a high-end cosmetic product or as part of an industrial application, it meets the highest standards expected by users worldwide.

Grinding is where mica takes on its powdered form. This phase requires specialized equipment capable of achieving the delicate fineness needed for various applications. The fine powder must meet specific parameters set by industries such as cosmetics, which demand ultra-fine, smooth mica for its light-reflecting properties. The grinding mills used can be configured to follow precise technical adjustments, balancing mechanical force to achieve the desired consistency without diminishing the material's quality. Through this process, technical prowess and meticulous attention to detail shine through, reflecting an authoritative understanding of mica's role across different mediums. Quality control plays a vital part in the process. With the help of sophisticated technology and skilled inspectors, every batch of mica powder is rigorously tested for uniformity, safety, and compliance with industry standards. Regular testing against international benchmarks ensures trustworthiness and safety in end products. Sustainability is increasingly crucial in today's production processes. Ethical sourcing and environmentally friendly practices are now integral to manufacturing mica powder. Industry leaders are committed to reducing the environmental impact through energy-efficient technologies and responsible mining practices, providing transparency in sourcing and production. This ethical approach serves to enhance both the authority and trustworthiness of mica powder producers on the global stage. In conclusion, the production of mica powder is a multifaceted process underpinned by a blend of skilled craftsmanship, technological innovation, and rigorous quality assurance. It stands as a model of expertise and trustworthiness in the industry, ensuring that whether the mica ends up in a high-end cosmetic product or as part of an industrial application, it meets the highest standards expected by users worldwide.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories