Jan . 14, 2025 11:27

Back to list

how is mica powder made

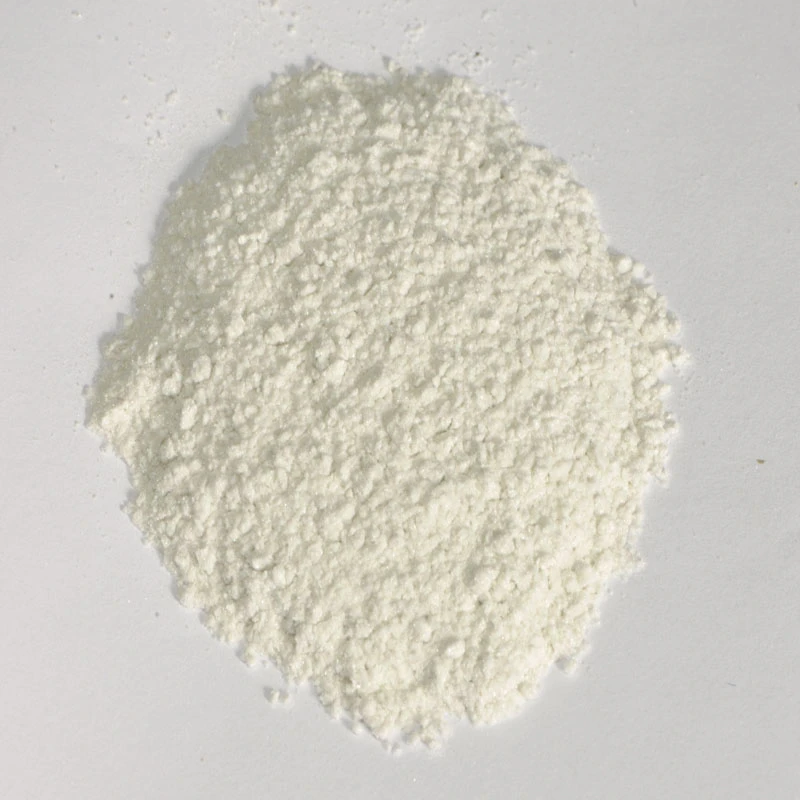

Mica powder, known for its shimmering quality and versatility, is extensively used in the beauty, arts, and industrial sectors. Understanding how mica powder is made involves a fascinating journey from natural mineral to refined end product, ensuring quality and sustainability at every step.

The grinding and pulverization process transforms the sorted and dried mica into the fine powder known for its characteristic sheen. State-of-the-art milling equipment ensures consistent particle size and texture, delivering a product ideal for various applications. During this stage, precision and experience are critical. Only through controlled grinding can the mica maintain its reflective properties and smooth finish, factors that lend credibility to the manufacturer and confidence to consumers. For added versatility and appeal, some mica powder is coated with titanium dioxide, enhancing its reflective properties and enabling a broader spectrum of colors. This refinement step is based on precise chemical engineering principles, requiring expertise in material sciences. The use of certificated and non-toxic coatings aligns with industry standards, ensuring consumer safety and trust in the product. Throughout the production process, credible manufacturers adhere to strict quality control measures. Each batch of mica powder is rigorously tested for composition, purity, and particle size distribution. Certification from recognized bodies often accompanies the product, underscoring the manufacturer's commitment to quality assurance and building consumer trust. In conclusion, the journey of mica powder from mineral to market-ready product is a blend of traditional craftsmanship and modern technology. Each step demands expertise, from the initial extraction to the final packaging, ensuring the mica powder not only shines literally but also stands out in terms of quality and reliability. By adhering to environmentally friendly practices and prioritizing safety and precision, manufacturers reinforce their authority and trustworthiness in the industry, offering consumers a product that dazzles and delivers.

The grinding and pulverization process transforms the sorted and dried mica into the fine powder known for its characteristic sheen. State-of-the-art milling equipment ensures consistent particle size and texture, delivering a product ideal for various applications. During this stage, precision and experience are critical. Only through controlled grinding can the mica maintain its reflective properties and smooth finish, factors that lend credibility to the manufacturer and confidence to consumers. For added versatility and appeal, some mica powder is coated with titanium dioxide, enhancing its reflective properties and enabling a broader spectrum of colors. This refinement step is based on precise chemical engineering principles, requiring expertise in material sciences. The use of certificated and non-toxic coatings aligns with industry standards, ensuring consumer safety and trust in the product. Throughout the production process, credible manufacturers adhere to strict quality control measures. Each batch of mica powder is rigorously tested for composition, purity, and particle size distribution. Certification from recognized bodies often accompanies the product, underscoring the manufacturer's commitment to quality assurance and building consumer trust. In conclusion, the journey of mica powder from mineral to market-ready product is a blend of traditional craftsmanship and modern technology. Each step demands expertise, from the initial extraction to the final packaging, ensuring the mica powder not only shines literally but also stands out in terms of quality and reliability. By adhering to environmentally friendly practices and prioritizing safety and precision, manufacturers reinforce their authority and trustworthiness in the industry, offering consumers a product that dazzles and delivers.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories