Jan . 26, 2025 04:27

Back to list

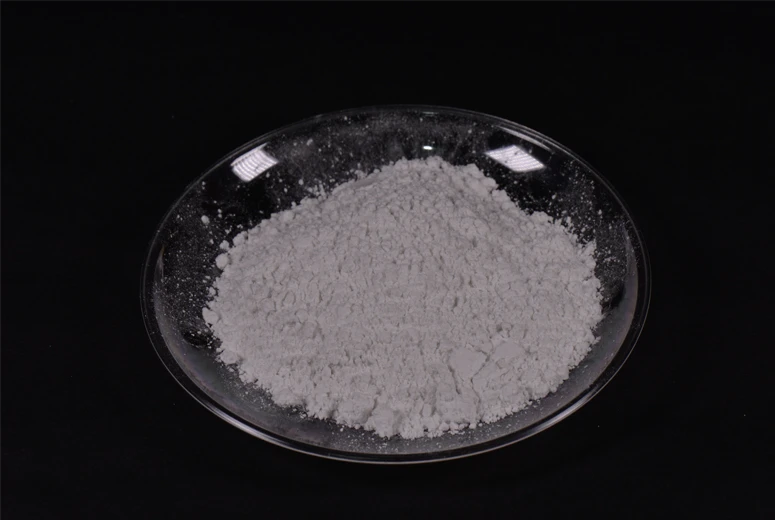

epoxy with mica powder

Epoxy with mica powder has emerged as a preferred choice for artisans, DIY enthusiasts, and professionals seeking to elevate the aesthetic appeal of their creations. This combination not only enhances the durability of projects but also adds a striking visual component, making it indispensable for anyone looking to create captivating surfaces. From countertops to decorative art pieces, epoxy and mica powder offer limitless possibilities.

Trust in the material quality is a cornerstone of successful projects. Selecting reputable brands for both epoxy resin and mica powder guarantees that the materials will perform as expected, minimizing issues like yellowing or uneven surfaces. Product reviews, industry certifications, and user testimonials are valuable resources in assessing product quality. Epoxy with mica powder sees widespread use in kitchen countertops, bar tops, and tabletops due to its ability to mimic natural stone at a fraction of the cost. The protective coat of resin provides an easy-to-clean, scratch-resistant surface perfect for high-traffic areas. For floors, the combination creates a durable, artistic alternative to conventional materials, adding character to interiors without sacrificing practicality. In the realm of arts and crafts, epoxy with mica powder offers a canvas of creativity. Artisans can encapsulate objects within the resin or create painted effects, offering limitless avenues for expression. These pieces can range from functional art, like custom coasters and jewelry, to large-scale installations that serve as statement pieces in residential or commercial spaces. Achieving a professional-grade result with epoxy and mica powder requires both patience and practice. Experienced individuals recommend starting with small projects to hone skills before attempting more ambitious undertakings. With each project, users learn the nuances of working with these materials, leading to greater confidence and expertise. In conclusion, the fusion of epoxy resin with mica powder offers unmatched creative potential and functional benefits. Through understanding and practice, users can harness these materials to transform ordinary surfaces into works of art, reflecting personal style and creativity. For anyone seeking to push the boundaries of conventional design, epoxy and mica powder provide an exceptional medium.

Trust in the material quality is a cornerstone of successful projects. Selecting reputable brands for both epoxy resin and mica powder guarantees that the materials will perform as expected, minimizing issues like yellowing or uneven surfaces. Product reviews, industry certifications, and user testimonials are valuable resources in assessing product quality. Epoxy with mica powder sees widespread use in kitchen countertops, bar tops, and tabletops due to its ability to mimic natural stone at a fraction of the cost. The protective coat of resin provides an easy-to-clean, scratch-resistant surface perfect for high-traffic areas. For floors, the combination creates a durable, artistic alternative to conventional materials, adding character to interiors without sacrificing practicality. In the realm of arts and crafts, epoxy with mica powder offers a canvas of creativity. Artisans can encapsulate objects within the resin or create painted effects, offering limitless avenues for expression. These pieces can range from functional art, like custom coasters and jewelry, to large-scale installations that serve as statement pieces in residential or commercial spaces. Achieving a professional-grade result with epoxy and mica powder requires both patience and practice. Experienced individuals recommend starting with small projects to hone skills before attempting more ambitious undertakings. With each project, users learn the nuances of working with these materials, leading to greater confidence and expertise. In conclusion, the fusion of epoxy resin with mica powder offers unmatched creative potential and functional benefits. Through understanding and practice, users can harness these materials to transform ordinary surfaces into works of art, reflecting personal style and creativity. For anyone seeking to push the boundaries of conventional design, epoxy and mica powder provide an exceptional medium.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories