Jan . 26, 2025 04:00

Back to list

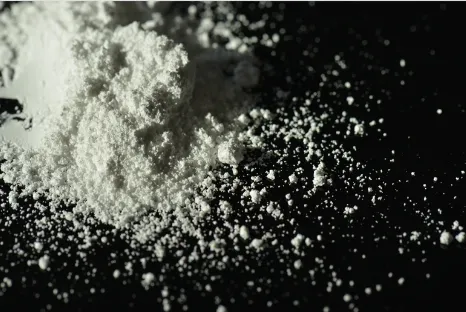

epoxy mica

Epoxy mica, despite its less mainstream notoriety, is a pioneering material making its mark across various industries. As a combination of epoxy resins and mica, it brings forth a unique blend of durability, insulation, and aesthetic properties. Its applications and benefits are rapidly catching the attention of professionals across technical fields.

Professionals in the field of epoxy formulations understand the critical role of each component. Selecting the right mechanical properties, thermal stability, and chemical resistance is paramount, and epoxy mica consistently outperforms other traditional materials. This consistent track record in various applications points to its authoritative presence in the sector and its potential for future innovations. Trust in epoxy mica is reinforced by rigorous testing and evaluation conducted in compliance with international standards. Manufacturers are committed to transparent practices, employing certified processes that ensure every batch meets industry-specific criteria. This dedication to quality assurance fosters trust among consumers, who can rely on epoxy mica for both general-purpose and specialized applications. The growing adoption of epoxy mica underscores its transformative impact across sectors. From essential industrial components to aesthetically pleasing surfaces, this material combines beauty with function—a quality that both consumers and manufacturers find irresistible. By addressing diverse needs and consistently delivering results, epoxy mica has cemented its standing as a versatile, authoritative choice in various industries, driving forward innovation and efficiency. Whether enhancing electrical systems, beautifying spaces, or crafting resilient art pieces, epoxy mica proves its mettle through unmatched expertise and reliability. Its journey from niche product to industry staple is defined by quality, performance, and an unwavering commitment to excellence—ensuring it remains a trusted name among professionals and innovators alike.

Professionals in the field of epoxy formulations understand the critical role of each component. Selecting the right mechanical properties, thermal stability, and chemical resistance is paramount, and epoxy mica consistently outperforms other traditional materials. This consistent track record in various applications points to its authoritative presence in the sector and its potential for future innovations. Trust in epoxy mica is reinforced by rigorous testing and evaluation conducted in compliance with international standards. Manufacturers are committed to transparent practices, employing certified processes that ensure every batch meets industry-specific criteria. This dedication to quality assurance fosters trust among consumers, who can rely on epoxy mica for both general-purpose and specialized applications. The growing adoption of epoxy mica underscores its transformative impact across sectors. From essential industrial components to aesthetically pleasing surfaces, this material combines beauty with function—a quality that both consumers and manufacturers find irresistible. By addressing diverse needs and consistently delivering results, epoxy mica has cemented its standing as a versatile, authoritative choice in various industries, driving forward innovation and efficiency. Whether enhancing electrical systems, beautifying spaces, or crafting resilient art pieces, epoxy mica proves its mettle through unmatched expertise and reliability. Its journey from niche product to industry staple is defined by quality, performance, and an unwavering commitment to excellence—ensuring it remains a trusted name among professionals and innovators alike.

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories