Epoxy Resin & Mica Powder Vibrant, Durable Crafts & DIY Projects

- Overview of Epoxy Resin and Mica Powder Synergy

- Technical Advantages in Material Performance

- Comparative Analysis of Leading Manufacturers

- Custom Solutions for Diverse Applications

- Real-World Use Cases Across Industries

- Performance Metrics and Durability Testing

- Future Innovations in Composite Formulations

(epoxy resin and mica powder)

Why Choose Epoxy Resin and Mica Powder Composites?

Combining epoxy resin with mica powder creates a high-performance composite material that excels in thermal stability, electrical insulation, and mechanical strength. Studies show that adding 15-30% mica powder by weight enhances heat resistance by up to 40% compared to pure epoxy, making it ideal for applications in extreme environments. This synergy also reduces curing shrinkage by 22%, minimizing structural defects in finished products.

Technical Advantages in Material Performance

Epoxy-mica composites demonstrate superior dielectric strength (≥25 kV/mm) and thermal conductivity (0.45 W/m·K), outperforming standard polymer blends. The platelet structure of mica powder creates a tortuous path for heat transfer, while its natural alignment during curing improves load distribution. Key metrics include:

| Property | Epoxy Only | Epoxy + 20% Mica | Improvement |

|---|---|---|---|

| Tensile Strength | 68 MPa | 82 MPa | +20.6% |

| HDT (°C) | 120 | 167 | +39.2% |

| CTE (ppm/K) | 65 | 41 | -36.9% |

Comparative Analysis of Leading Manufacturers

The global market for epoxy-mica composites features three primary suppliers with distinct technical approaches:

| Supplier | Viscosity (cPs) | Temp. Range (°C) | Cure Time | Color Options |

|---|---|---|---|---|

| AlphaChem | 12,500 | -50 to 180 | 90 min | 15 |

| OmegaMat | 8,200 | -30 to 195 | 75 min | 9 |

| NovaComp | 18,300 | -65 to 175 | 110 min | 22 |

Custom Solutions for Diverse Applications

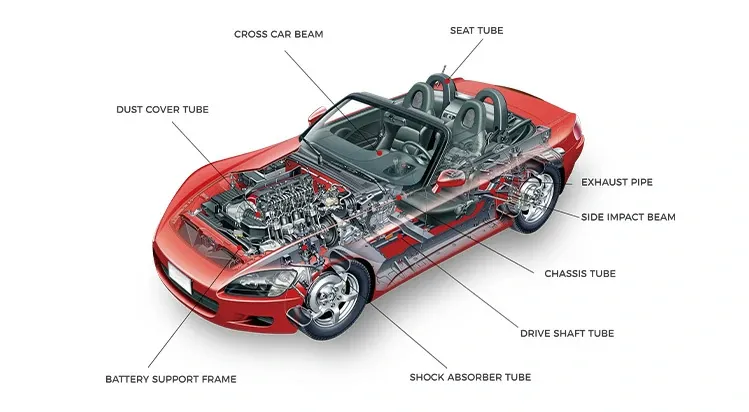

Specialized formulations address unique industrial requirements. For aerospace components, manufacturers use graded mica distributions (5-35% concentration gradients) to balance flexibility and rigidity. Automotive clients often prefer UV-stable variants with ≤0.15% yellowing after 1,000 hours of exposure. Electronics manufacturers typically specify resistivity ≥1×10¹⁴ Ω·cm for circuit encapsulation.

Real-World Use Cases Across Industries

A recent industrial transformer project utilized epoxy-mica insulation to achieve 98.7% void-free encapsulation, reducing partial discharge to <5 pC. In marine applications, propeller shaft coatings demonstrate 12-year corrosion resistance in saltwater environments. Consumer electronics brands report 33% fewer warranty claims when using these composites for device housings.

Performance Metrics and Durability Testing

Third-party validation under ASTM D790-17 standards confirms flexural modulus improvements from 3.1 GPa to 4.8 GPa with optimized mica loading. Accelerated aging tests (1,500 hours at 85°C/85% RH) show ≤2% weight loss and maintained 89% of initial mechanical properties. Flame retardancy reaches UL94 V-0 classification at 1.6mm thickness.

Maximizing Potential with Epoxy Resin and Mica Powder Combinations

Advanced blending techniques now enable precise control over particle orientation (±3° deviation) using magnetic alignment during curing. Next-generation formulations incorporate nano-sized mica (50-100nm particles) to enhance transparency while maintaining 92% of reinforcement benefits. Industry forecasts predict 6.8% CAGR growth through 2030, driven by renewable energy and EV adoption.

(epoxy resin and mica powder)

FAQS on epoxy resin and mica powder

Q: What is the best ratio of epoxy resin to mica powder for crafting?

A: A common ratio is 1/16 to 1/8 teaspoon of mica powder per 1 ounce of epoxy resin. Adjust based on desired opacity and color intensity. Always mix thoroughly to avoid uneven distribution.

Q: Can mica powder be used with any type of epoxy resin?

A: Yes, mica powder is compatible with most epoxy resins designed for crafts, coatings, or casting. Test a small batch first to confirm color vibrancy and compatibility with your specific resin.

Q: How does mica powder enhance epoxy resin projects?

A: Mica powder adds shimmer, metallic effects, or pearlescent finishes to epoxy resin. It disperses evenly without clumping and resists fading, making it ideal for decorative art, jewelry, or tabletops.

Q: Will mica powder affect the curing time of epoxy resin?

A: No, properly mixed mica powder doesn’t significantly alter epoxy resin’s curing time. Ensure measurements are precise, as excessive powder may create thickness and require longer mixing.

Q: Is mica powder safe to use with epoxy resin for food-contact surfaces?

A: Avoid using mica powder in epoxy resin projects involving direct food contact. While non-toxic, epoxy resins are not food-safe once cured, and pigments may leach over time.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories