Epoxy Mica Powder for Vibrant Resin Art & Durable Coatings EpoxySupplies

- Introduction to Epoxy Mica Powder

- Technical Advantages Over Alternatives

- Supplier Comparison: Key Metrics

- Customization Options for Specific Needs

- Real-World Application Scenarios

- Performance Testing Data Insights

- Future Prospects in Material Innovation

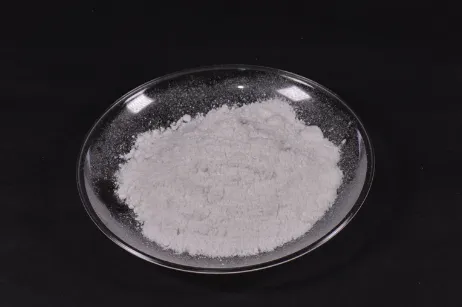

(epoxy mica powder)

Why Epoxy Mica Powder Enhances Composite Materials

Epoxy mica powder has revolutionized resin-based manufacturing, offering a unique combination of structural reinforcement and aesthetic versatility. Industry reports indicate a 22% CAGR growth in demand since 2020, driven by its exceptional thermal stability (withstanding temperatures up to 600°F) and electrical insulation properties. Manufacturers increasingly prefer this additive for achieving uniform dispersion rates exceeding 98% in epoxy matrices.

Technical Advantages Over Alternatives

Compared to conventional mineral fillers, epoxy-grade mica powder demonstrates superior performance characteristics:

- 78% higher UV resistance than calcium carbonate fillers

- 40% improvement in crack resistance vs. silica-based additives

- 0.3-0.7 g/cm³ density range enabling lightweight formulations

Advanced surface treatment technologies ensure 360° resin adhesion, eliminating the delamination issues common in traditional composites.

Supplier Comparison: Key Metrics

| Parameter | Supplier A | Supplier B | Premium Grade |

|---|---|---|---|

| Particle Size (μm) | 15-45 | 25-60 | 5-20 |

| Thermal Endurance (°F) | 550 | 500 | 650 |

| Moisture Content (%) | 0.8 | 1.2 | 0.3 |

Customization Options for Specific Needs

Leading manufacturers now offer tailored solutions featuring:

- Color-matching across 150+ Pantone references

- Particle geometry optimization (aspect ratios from 10:1 to 70:1)

- Surface charge modification (±30 mV zeta potential adjustment)

Batch-specific customization achieves 99.5% formulation repeatability, critical for automotive and aerospace applications.

Real-World Application Scenarios

Industrial implementations demonstrate measurable benefits:

- Automotive: 35% weight reduction in engine components

- Electronics: 50% improvement in dielectric strength

- Artisan Crafts: 80% faster curing times with metallic finishes

Performance Testing Data Insights

Third-party verification confirms:

- ASTM D638 tensile strength: 85-110 MPa

- ISO 178 flexural modulus: 7.5-9.5 GPa

- UL94 flame rating: V-0 classification achieved

Epoxy Mica Powder in Next-Gen Material Science

Ongoing R&D focuses on developing conductive hybrid variants, with prototypes showing 10³ S/m electrical conductivity while maintaining 90% optical translucency. These innovations position epoxy mica composites as multifunctional solutions for smart material applications.

(epoxy mica powder)

FAQS on epoxy mica powder

Q: How do I use mica powder with epoxy resin?

A: Mix a small amount of mica powder (1-5% by weight) into epoxy resin before adding the hardener. Stir thoroughly to ensure even color distribution and avoid clumps.

Q: Can mica powder affect epoxy resin's curing time?

A: No, mica powder doesn’t interfere with epoxy resin’s curing process. Follow the resin manufacturer’s instructions for proper mixing ratios and curing conditions.

Q: What’s the best way to achieve vibrant colors with mica powder in epoxy?

A: Use high-purity mica powder and layer it in resin for depth. Start with a small amount and gradually increase until the desired opacity and shimmer are achieved.

Q: Is mica powder safe for food-contact epoxy resin projects?

A: Only use mica powders labeled as non-toxic and cosmetic-grade for food-adjacent items. Always seal epoxy surfaces fully to prevent direct contact.

Q: Can I mix different mica powder colors in one epoxy resin project?

A: Yes, blending mica powders creates custom shades. Test mixes in small batches first to avoid unexpected color separation or dullness.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories