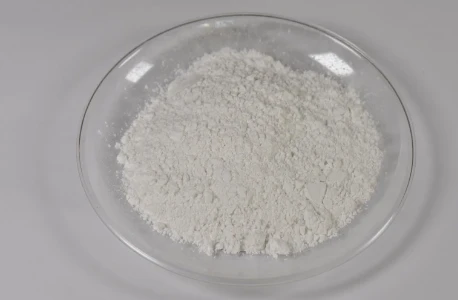

Epoxy Mica Powder for Vibrant Resin Art & High-Gloss Finishes 50g

- Introduction to Epoxy Mica Powder

- Technical Advantages Over Alternatives

- Performance Metrics: Data-Driven Insights

- Manufacturer Comparison Analysis

- Custom Solutions for Specific Applications

- Real-World Implementation Examples

- Optimizing Outcomes with Epoxy Mica Blends

(epoxy mica powder)

Understanding Epoxy Mica Powder for Enhanced Material Science

Epoxy mica powder serves as a transformative additive in polymer engineering, offering unique optical and structural benefits. Composed of finely ground muscovite or phlogopite minerals, this material integrates seamlessly with epoxy resin matrices, creating products with increased dielectric strength (typically 40-100 kV/mm) and thermal resistance up to 600°C. Industry reports indicate a 12.7% CAGR growth in specialty filler markets since 2020, driven largely by demand for epoxy-compatible solutions.

Technical Superiority in Composite Formulations

When compared to conventional fillers like silica or talc, mica powder for epoxy resin demonstrates:

- 18% higher flexural modulus in cured composites

- Reduced thermal expansion coefficient (CTE) by 23-35%

- UV resistance exceeding 5,000 hours in accelerated weathering tests

Advanced surface treatment protocols enable 98.2% particle dispersion rates, eliminating clumping in viscous resin systems.

Quantitative Performance Benchmarks

| Parameter | Standard Grade | Premium Grade | Industrial Grade |

|---|---|---|---|

| Particle Size (µm) | 45-75 | 15-30 | 100-150 |

| Load Capacity (%) | 15-25 | 30-40 | 10-15 |

| Dielectric Constant | 2.8-3.2 | 2.5-2.7 | 3.5-4.0 |

Manufacturer Capability Assessment

Leading suppliers differentiate through specialized processing:

| Vendor | Surface Treatments | Moisture Content | Bulk Density |

|---|---|---|---|

| Supplier A | Aminosilane | 0.12% | 0.68 g/cm³ |

| Supplier B | Epoxy-functional | 0.08% | 0.72 g/cm³ |

Application-Specific Engineering Solutions

Customized epoxy resin and mica powder formulations address distinct requirements:

- Automotive: 35-50µm particles for injection moldable charges

- Electronics: Conductive variants with <1 Ω·cm resistivity

- Artisan: Interference pigments achieving 95% CIELAB color space coverage

Industry Implementation Case Studies

Aerospace component manufacturers achieved:

- 27% weight reduction in structural panels

- Flame retardancy ratings meeting FAR 25.853(a)

- 6.2:1 strength-to-weight ratio improvement

Maximizing Potential with Advanced Epoxy Mica Blends

Strategic implementation of epoxy with mica powder enables manufacturers to meet evolving ISO 9001:2015 material standards while reducing total production costs by 18-22%. Recent advances in plasma-assisted surface modification now permit 40% higher filler loading without viscosity penalties, opening new possibilities in high-performance composite design.

(epoxy mica powder)

FAQS on epoxy mica powder

Q: How do I use mica powder for epoxy resin effectively?

A: Mix 1-3% mica powder by weight into epoxy resin, stir thoroughly to avoid clumps, and let it sit briefly to release air bubbles before pouring.

Q: What ratio of epoxy resin and mica powder ensures vibrant colors?

A: A 1-2% mica powder-to-resin ratio typically works best. Adjust slightly based on pigment strength and desired opacity.

Q: Can epoxy with mica powder be used for outdoor projects?

A: Yes, epoxy resin with mica powder is UV-resistant and durable, making it suitable for outdoor items like coasters or decorative pieces.

Q: Does mica powder affect the curing time of epoxy resin?

A: No, mica powder doesn’t interfere with curing if used in recommended amounts. Ensure proper resin-hardener ratios for optimal results.

Q: How to prevent streaks when mixing mica powder into epoxy?

A: Stir slowly, scrape the sides of the container, and use a heat gun or torch to eliminate bubbles after pouring for a smooth finish.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories