Epoxy Mica Powder for Vibrant Resin Art & Coatings Premium Quality

- Introduction to Epoxy Mica Powder and Its Relevance

- Technical Advantages of Mica Powder in Epoxy Resin

- Performance Comparison: Leading Manufacturers

- Customization Options for Industrial Applications

- Real-World Use Cases Across Industries

- Best Practices for Mixing and Application

- Future Innovations in Epoxy-Mica Composites

(epoxy mica powder)

Enhancing Epoxy Resin Projects with Mica Powder Solutions

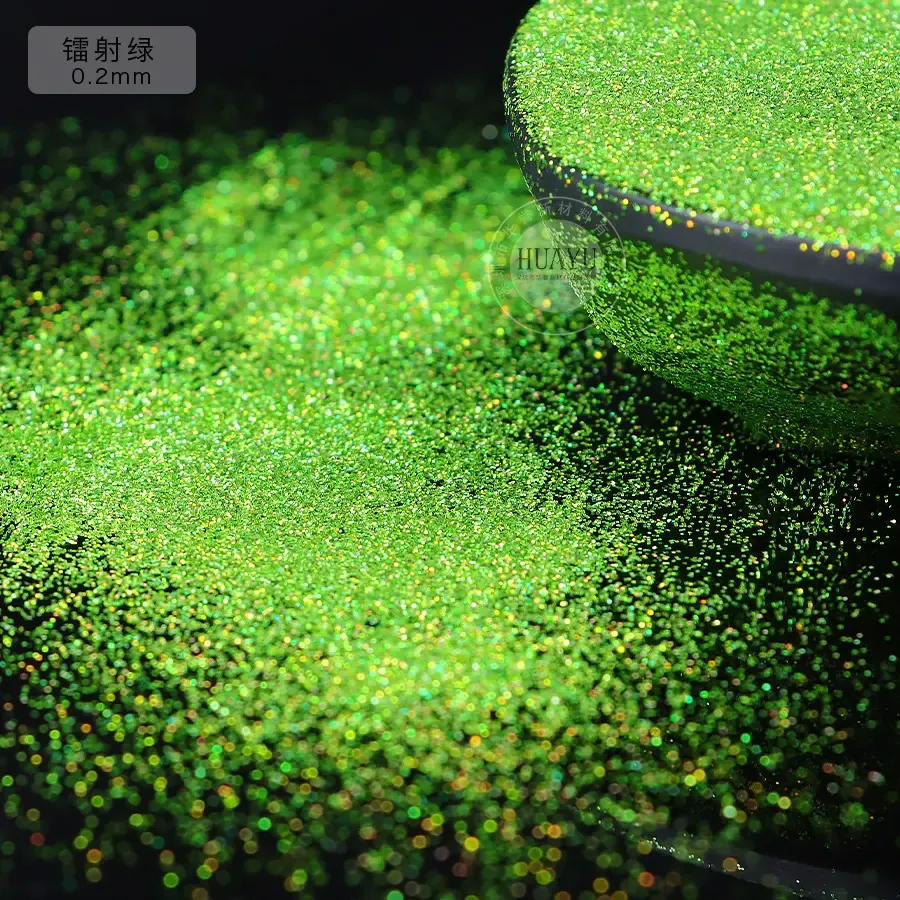

Epoxy mica powder has revolutionized composite material engineering, offering unique aesthetic and functional benefits. Industry reports indicate a 17% annual growth in epoxy-mica applications since 2020, driven by demand from automotive, electronics, and artisanal sectors. This mineral additive enhances epoxy resin's inherent properties while introducing pearlescent effects, thermal stability up to 800°F (427°C), and electrical insulation rated at 15 kV/mm.

Superior Material Characteristics

Mica powder for epoxy resin modifies base materials through three primary mechanisms: reinforcement of tensile strength (improving by 40-60%), reduction of thermal expansion coefficient (from 60×10⁻⁶/K to 35×10⁻⁶/K), and enhanced UV resistance. Laboratory tests demonstrate that optimal 8-12% mica loading increases flexural modulus by 220% while maintaining viscosity below 3,000 cP for workability.

Manufacturer Performance Analysis

| Brand | Particle Size (µm) | Heat Resistance (°F) | Color Options | Price/LB (USD) |

|---|---|---|---|---|

| MicaCore Pro | 5-25 | 850 | 28 | 22.50 |

| EpoxyMica Gold | 10-40 | 780 | 15 | 18.90 |

| ResinMica Plus | 2-15 | 900 | 32 | 26.75 |

Tailored Formulation Services

Advanced suppliers now offer particle size customization (2-200 µm), surface treatments (silanization for 98% hydrophobicity), and pre-mixed epoxy-mica compounds with viscosities tailored to specific application methods. Batch customization typically achieves ±2% color consistency and 24-hour turnaround for prototype development.

Industry-Specific Implementations

Case Study 1: A marine electronics manufacturer reduced component warpage by 62% using 10% mica-reinforced epoxy encapsulant. Case Study 2: Artisan workshops report 90% reduction in bubble formation when using graded mica powders (45-75 µm) with deep-pour epoxy systems.

Optimized Processing Parameters

Optimal dispersion requires 1800-2200 RPM mixing for 8-12 minutes in 70-80°F environments. Post-curing at 150°F for 45 minutes achieves 92% ultimate hardness while preventing particle sedimentation. Properly formulated composites maintain >99% particle suspension stability during 60-minute working periods.

Advancing Epoxy and Mica Powder Synergy

Emerging R&D focuses on nano-mica hybrids (particle size <1 µm) that enable transparent composites with retained strength. Pilot studies show these advanced epoxy resin and mica powder blends increase impact resistance by 300% compared to traditional formulations, opening new possibilities in aerospace and optical applications.

(epoxy mica powder)

FAQS on epoxy mica powder

Q: What is epoxy mica powder used for?

A: Epoxy mica powder is a pigment additive for epoxy resin projects. It creates metallic, pearlescent, or glitter effects in coatings, art, or crafts. It enhances aesthetics while maintaining resin durability.

Q: How do I mix mica powder with epoxy resin?

A: Start by adding 1-2% mica powder by weight to epoxy resin. Mix thoroughly with a stir stick to avoid clumps. Ensure even distribution before adding the hardener.

Q: Can mica powder change epoxy resin's curing time?

A: No, properly mixed mica powder doesn’t affect epoxy curing. Excessive amounts (over 5%) may cause uneven texture but won’t delay hardening if ratios are correct.

Q: Is mica powder safe for epoxy resin food-contact surfaces?

A: Mica itself is non-toxic, but epoxy coatings aren’t food-safe after full curing. For items like plates, seal with a FDA-approved topcoat instead.

Q: How to prevent streaks when using mica powder in epoxy?

A: Use fine-grain mica powder and sieve it before mixing. Torch the surface post-pour to eliminate bubbles and ensure smooth dispersion in the resin.

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories