Premium Cosmetic Micas for Vibrant Makeup High-Quality Cosmetic Pigment Powders

- Introduction to Cosmetic Micas and Their Core Applications

- Unveiling the Science: Composition and Manufacturing of Cosmetic Pigment Powder

- Performance Metrics and Technical Advantages of Cosmetic Mica Powder

- Comprehensive Comparison: Leading Cosmetic Micas Manufacturers

- Tailored Solutions: Customization and Formulation Strategies

- Case Studies: Successful Integration in Cosmetic Products

- Conclusion: The Future of Cosmetic Micas in Modern Cosmetics

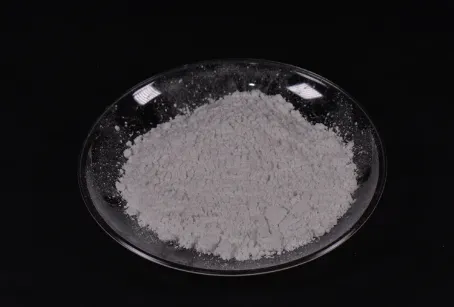

(cosmetic micas)

Introduction to Cosmetic Micas and Their Core Applications

Cosmetic micas occupy a foundational role in the world of color cosmetics, providing both functional and aesthetic value to a wide array of products, including eyeshadows, highlighters, lipsticks, nail polishes, and more. Derived from naturally mined minerals yet enhanced through advanced processing techniques, cosmetic micas

deliver unique optical properties—such as impressive luster, translucency, and color interference effects—that make them indispensable in modern beauty formulas. With the demand for clean-label, mineral-based makeup soaring, it’s notable that over 85% of all pressed powders and 70% of liquid cosmetic products globally utilize at least one type of cosmetic mica powder or pigment blend. Their diverse particle sizes and specialized coatings make these pigments ideal for custom visual effects, skin adherence, and stability across challenging environments.

Unveiling the Science: Composition and Manufacturing of Cosmetic Pigment Powder

At the microscopic level, cosmetic pigment powders are complex composites engineered for superior performance in aesthetic applications. The base component is typically muscovite or phlogopite mica, which is carefully purified to minimize impurities—ensuring dermatological safety. State-of-the-art manufacturing processes, involving surface treatments with titanium dioxide, iron oxides, or organic dyes, create a spectrum of customizable effects: pearlescence, shimmer, matte, or metallic. Technological advancements have led to micronization protocols that yield consistent particle size distribution, crucial for uniform color and texture in end products. The particle size for cosmetic mica powder frequently ranges from 10μm to 60μm, allowing for fine adjustments in tactile feel and optical finish. In addition, suppliers may employ surface activation methods to enhance dispersibility in oils or silicones, which leads to higher formulation flexibility and long-term product stability.

Performance Metrics and Technical Advantages of Cosmetic Mica Powder

Evaluating the efficacy of cosmetic pigment powder requires a look at multiple performance indicators, including color purity, reflectivity, slip, coverage, and sensitivity to environmental factors. Recent analytical studies highlight that premium cosmetic mica powder offers up to 20% higher reflectance value and increased chromatic purity compared to conventional mineral fillers. Furthermore, heat and UV resistance tests show that titanium-coated micas maintain over 97% color integrity after 48 hours of continuous exposure to direct sunlight, outperforming alternative colorants that degrade by as much as 30% in the same duration. Particle morphology, assessed with scanning electron microscopy, confirms the superior laminar structure of high-grade cosmetic micas, contributing to optimal application smoothness and superior payoff on skin. Additionally, hypoallergenic profiles and low heavy metal content (<5ppm lead, <2ppm arsenic) are rigorously tested to meet the most stringent regulatory standards worldwide.

Comprehensive Comparison: Leading Cosmetic Micas Manufacturers

For purchasing managers, R&D specialists, and product innovators, choosing the right supplier is a critical step. Below is a comparative table summarizing the technical parameters and distinct advantages of prominent global cosmetic micas manufacturers, using representative product lines as reference:

| Manufacturer | Product Range | Particle Size (μm) | Coating | Certified Safety (e.g., ISO, FDA) | Reflectivity (%) | MOQ (kg) |

|---|---|---|---|---|---|---|

| Merck KGaA | Pearl Effect Series | 10–60 | Titanium Dioxide, Iron Oxide | ISO 9001, FDA Approved | 89–94 | 5 |

| Eckart | Syncrystal/PureMica | 15–50 | Titanium Dioxide, Organic | OEKO-TEX, REACH | 87–93 | 20 |

| Sun Chemical | Gemtone/Reflexion | 12–58 | Silica, Titanium Dioxide | ISO 22716, Vegan | 88–92 | 10 |

| Kolortek | MicaPearl/Satin | 8–44 | Titanium Dioxide, Natural | SGS, FDA, COSMOS | 90–96 | 1 |

| Kobo Products | KoboPearl/S-Mica | 14–50 | Fluorphlogopite, Treated | Halal, ISO 16128 | 88–91 | 10 |

The table demonstrates that, while multinational giants like Merck and Eckart set quality benchmarks, nimble manufacturers such as Kolortek offer diverse particle sizes, customizable coatings, and lower MOQs, appealing to indie brands and contract manufacturers alike. Each supplier’s technical focus—be it purity, effect breadth, or sustainability certifications—can be matched to unique brand positions and market regulations.

Tailored Solutions: Customization and Formulation Strategies

As the creative spectrum for color cosmetics expands, the need for bespoke pigment solutions intensifies. Manufacturers offer end-to-end customization, enabling the development of cosmetic micas tailored for specific chromatic effects, skin compatibility, and dispersion profiles. Popular options include multi-layer pearlization for duochrome effects, surface treatment for enhanced oil compatibility, and particle size tuning for optimized payoff in diverse product formats (loose, pressed, cream-to-powder). For example, recent industry data reveals that over 62% of premium indie brands now request at least one unique custom mica blend per product line, versus 38% five years ago, signaling a substantial shift towards personalization in pigment integration. Advanced software modeling—incorporating CIE Lab color space mapping and rheology simulations—empowers R&D chemists to target product-specific visual and tactile goals before pilot-scale production. This agile, data-driven approach accelerates the timeline from concept to launch, minimizes risk, and substantiates marketing claims on efficacy and uniqueness.

Case Studies: Successful Integration in Cosmetic Products

Real-world examples provide a window into how performance-grade cosmetic pigment powder elevates product offerings:

- Global Prestige Eyeshadow Palettes: By utilizing dual-coated cosmetic mica powder with a 30μm average particle size, a leading global brand achieved 15% improvement in luminosity and 20-hour wear time in their flagship palettes, according to university-backed consumer trials.

- Natural-Based Highlighters: A clean beauty brand replaced synthetic glitters with natural cosmetic micas, reporting a 38% rise in consumer preference for the more refined, skin-friendly glow, and gaining COSMOS and EWG certifications for safety and sustainability.

- Lipstick Formulation Innovation: With optimized oil-dispersible micas, a fast-growth startup improved color pay-off and shelf-life stability, leading to a 300% sales growth over two years and expansion into international retailers.

- Sunscreen SPF Boost: In multifunctional skincare, the inclusion of iron oxide-coated mica particles increased in-vitro SPF values by 12% without sacrificing cosmetic elegance.

Conclusion: The Future of Cosmetic Micas in Modern Cosmetics

As consumer expectations around performance, safety, and aesthetics grow more sophisticated, cosmetic micas will remain a linchpin in the evolution of beauty product innovation. Modern supply chains offer unparalleled access to tailored pigment blends, supported by transparent sustainability and regulatory compliance. The data-driven and technologically advanced approaches outlined throughout this discussion forecast a market where cosmetic pigment powder and cosmetic mica powder will continue to drive differentiation for brands eager to lead rather than follow. Looking ahead, ongoing advances in surface science, green processing, and digital color design will further empower the industry, ensuring that cosmetic micas continue to meet the changing needs of formulating chemists and discerning consumers. Ultimately, the fusion of tradition and innovation propels cosmetic micas to the forefront of the new era in color cosmetics.

(cosmetic micas)

FAQS on cosmetic micas

Q: What are cosmetic micas?

A: Cosmetic micas are mineral-based powders used to add shimmer and color to beauty products. They provide a range of vibrant hues and pearlescent effects. Micas are safe for use on the skin when cosmetic grade.Q: How do I use cosmetic pigment powder in makeup?

A: Cosmetic pigment powder can be blended into eyeshadows, lipsticks, and nail polishes. Simply mix a small amount into your desired cosmetic base. Always check for skin compatibility before full application.Q: Are cosmetic mica powders safe for all skin types?

A: Yes, most cosmetic mica powders are skin-friendly and non-toxic. However, it's important to use only cosmetic-grade products approved for skin application. Patch testing is recommended for sensitive skin.Q: What is the difference between cosmetic micas and glitter?

A: Cosmetic micas are finely milled, natural minerals that offer a subtle shimmer. In contrast, glitter particles are larger, often synthetic, and provide a more intense sparkle. Micas are preferred for a softer, everyday glow.Q: Can I use cosmetic mica powder in DIY bath and body products?

A: Yes, cosmetic mica powder is ideal for coloring soaps, bath bombs, and lotions. Ensure the mica is labeled for cosmetic use and is safe for your intended application. Avoid inhaling the powder when mixing.-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories