Jan . 24, 2025 03:55

Back to list

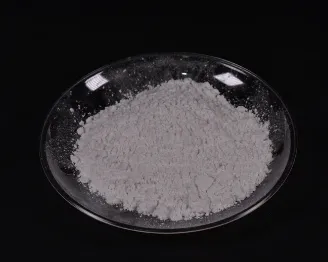

large mica flakes

Coloring melt and pour soap with mica involves a harmonious blend of creativity and chemistry, offering a personalized touch to soap crafting that both beginners and experienced artisans can master. Mica, a natural mineral, is cherished for its vibrant hues and shimmering qualities, making it a favorite in the cosmetic industry. When used correctly, it can transform a simple soap into a piece of functional art, adding both aesthetic and sensory appeal to everyday hygiene products.

It's also wise to perform a small test pour to evaluate the color once the soap is fully hardened. This test will confirm if the concentration of mica yields the desired hue and shimmer, allowing further adjustments before bulk pouring. Beyond the mechanics, creativity reigns supreme in soap design. Combining mica colors can result in stunning effects—swirling different shades to simulate marble or layering colors for ombre designs transforms the soap into not just a cleansing agent, but a decorative piece. Upon achieving the perfect shade and design, pour the mixture into molds. Various mold shapes can enhance the final product’s aesthetic, from traditional bars to intricate novelty forms. Allow the soap to cool and set thoroughly, usually taking a minimum of 4-6 hours, preferably overnight to ensure comprehensive solidification. Once demolded, mica-colored melt and pour soaps can be stored in an airtight container to maintain moisture levels and preserve scent. Moreover, well-executed soaps may serve as premium handmade gifts or profitable products for small business ventures. In conclusion, coloring melt and pour soap with mica not only enriches personal crafting projects but enhances professional offerings within the homemade beauty product market. Attention to detail, combined with creative fervor and understanding of the material properties, results in products that are as enjoyable to make as they are to use.

It's also wise to perform a small test pour to evaluate the color once the soap is fully hardened. This test will confirm if the concentration of mica yields the desired hue and shimmer, allowing further adjustments before bulk pouring. Beyond the mechanics, creativity reigns supreme in soap design. Combining mica colors can result in stunning effects—swirling different shades to simulate marble or layering colors for ombre designs transforms the soap into not just a cleansing agent, but a decorative piece. Upon achieving the perfect shade and design, pour the mixture into molds. Various mold shapes can enhance the final product’s aesthetic, from traditional bars to intricate novelty forms. Allow the soap to cool and set thoroughly, usually taking a minimum of 4-6 hours, preferably overnight to ensure comprehensive solidification. Once demolded, mica-colored melt and pour soaps can be stored in an airtight container to maintain moisture levels and preserve scent. Moreover, well-executed soaps may serve as premium handmade gifts or profitable products for small business ventures. In conclusion, coloring melt and pour soap with mica not only enriches personal crafting projects but enhances professional offerings within the homemade beauty product market. Attention to detail, combined with creative fervor and understanding of the material properties, results in products that are as enjoyable to make as they are to use.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories