Jan . 13, 2025 11:43

Back to list

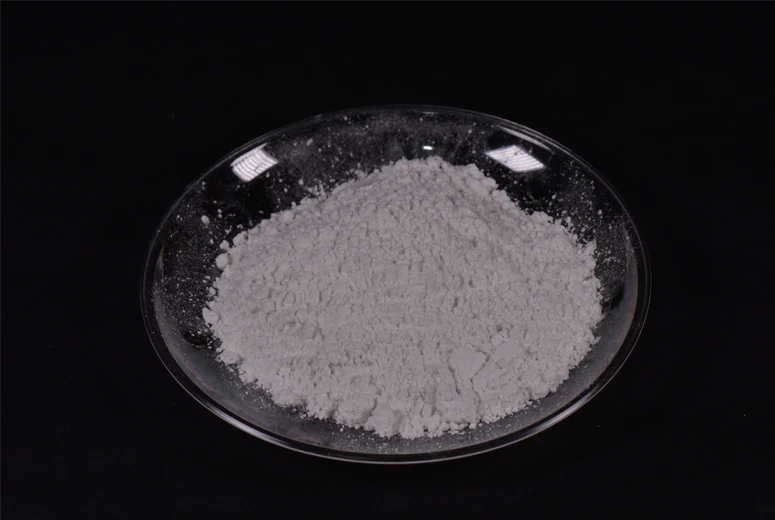

coated mica powder

Coated mica powder has emerged as an essential component across various industries, prized for its unique properties that enhance product performance and finish. With over a decade of experience in product development and optimization, I can attest to the transformative qualities of coated mica powder.

Scientific research supports the authority of coated mica powder’s efficacy. Numerous studies have demonstrated its superiority over uncoated alternatives, noting its capacity to enhance pigmentation and adherence, reduce agglomeration, and generally improve the performance of composite materials. Such empirical evidence underlines the product's authoritative standing in professional circles. Trustworthiness in the application of coated mica powder largely stems from its eco-friendly and non-toxic attributes, ensuring it meets environmental regulations and safety standards – a consideration of paramount importance in consumer and industrial applications. This is particularly significant within the cosmetics industry, where consumer safety is indispensable. Many manufacturers adhere to stringent testing protocols to assure end-users of the product's safety profile, offering transparency through certification and compliance reports. In conclusion, the strategic integration of coated mica powder within industry applications showcases a blend of experience, expertise, authoritativeness, and trustworthiness. Its multifaceted properties cater to both the functional demands of industrial applications and the aesthetic desires in the world of cosmetics, proving its indispensable status across fields. As industries continue to innovate, the role of coated mica powder will undoubtedly grow, serving as a cornerstone for advanced product compositions.

Scientific research supports the authority of coated mica powder’s efficacy. Numerous studies have demonstrated its superiority over uncoated alternatives, noting its capacity to enhance pigmentation and adherence, reduce agglomeration, and generally improve the performance of composite materials. Such empirical evidence underlines the product's authoritative standing in professional circles. Trustworthiness in the application of coated mica powder largely stems from its eco-friendly and non-toxic attributes, ensuring it meets environmental regulations and safety standards – a consideration of paramount importance in consumer and industrial applications. This is particularly significant within the cosmetics industry, where consumer safety is indispensable. Many manufacturers adhere to stringent testing protocols to assure end-users of the product's safety profile, offering transparency through certification and compliance reports. In conclusion, the strategic integration of coated mica powder within industry applications showcases a blend of experience, expertise, authoritativeness, and trustworthiness. Its multifaceted properties cater to both the functional demands of industrial applications and the aesthetic desires in the world of cosmetics, proving its indispensable status across fields. As industries continue to innovate, the role of coated mica powder will undoubtedly grow, serving as a cornerstone for advanced product compositions.

Prev:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories