Feb . 18, 2025 07:28

Back to list

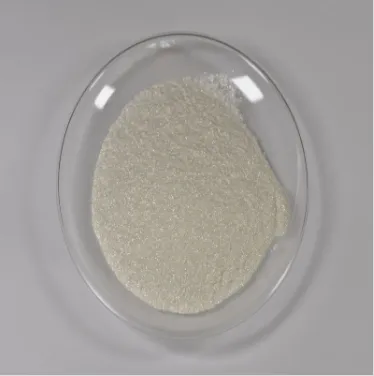

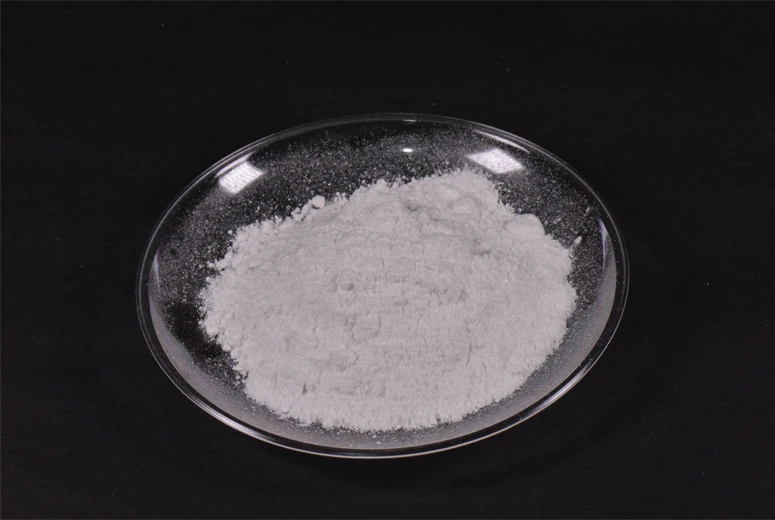

edible mica powder

Coated mica powder embodies the elegance of mother nature with a distinct sparkle that amplifies any product it touches. Elevate your offerings by diving deep into the world of mica and the meticulous processes involved in crafting the finest coated versions, drawing from extensive industry expertise and credible experiences.

Sustainability is another pivotal aspect of coated mica powders. Procured from ethically sourced mines and subjected to rigorous environmental testing, these powders align with eco-conscious values, reducing environmental impact while maintaining quality. This speaks to a growing demand for environmentally responsible products where trust and authenticity are paramount. Safety remains a cornerstone for all mica applications, ensuring consumer trust. Rigorous standards are adhered to during the manufacturing process to eliminate contaminants and potential allergens, with coated versions specifically designed to minimize any harmful repercussions when used in personal care products. A reputable dermatologist reassures that these products, when applied, maintain skin safety and integrity, building consumer confidence and loyalty. Incorporating coated mica powder into products not only elevates their visual and structural appeal but also aligns with industry standards of quality and safety. It is not just about the sparkle; it is about crafting experiences that are memorable and respected, backed by expertise and trust. To remain ahead in the competitive landscape, embracing the transformative potential of coated mica powder is not merely an option, but a strategic necessity. Opt for innovation, backed by experience and expertise, to transform how your brand is perceived in the marketplace. With coated mica powder, you hold the key to unlocking unprecedented brilliance in your products, assured by authoritative research and unwavering reliability.

Sustainability is another pivotal aspect of coated mica powders. Procured from ethically sourced mines and subjected to rigorous environmental testing, these powders align with eco-conscious values, reducing environmental impact while maintaining quality. This speaks to a growing demand for environmentally responsible products where trust and authenticity are paramount. Safety remains a cornerstone for all mica applications, ensuring consumer trust. Rigorous standards are adhered to during the manufacturing process to eliminate contaminants and potential allergens, with coated versions specifically designed to minimize any harmful repercussions when used in personal care products. A reputable dermatologist reassures that these products, when applied, maintain skin safety and integrity, building consumer confidence and loyalty. Incorporating coated mica powder into products not only elevates their visual and structural appeal but also aligns with industry standards of quality and safety. It is not just about the sparkle; it is about crafting experiences that are memorable and respected, backed by expertise and trust. To remain ahead in the competitive landscape, embracing the transformative potential of coated mica powder is not merely an option, but a strategic necessity. Opt for innovation, backed by experience and expertise, to transform how your brand is perceived in the marketplace. With coated mica powder, you hold the key to unlocking unprecedented brilliance in your products, assured by authoritative research and unwavering reliability.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories