Feb . 08, 2025 00:35

Back to list

can you use mica powder in soap

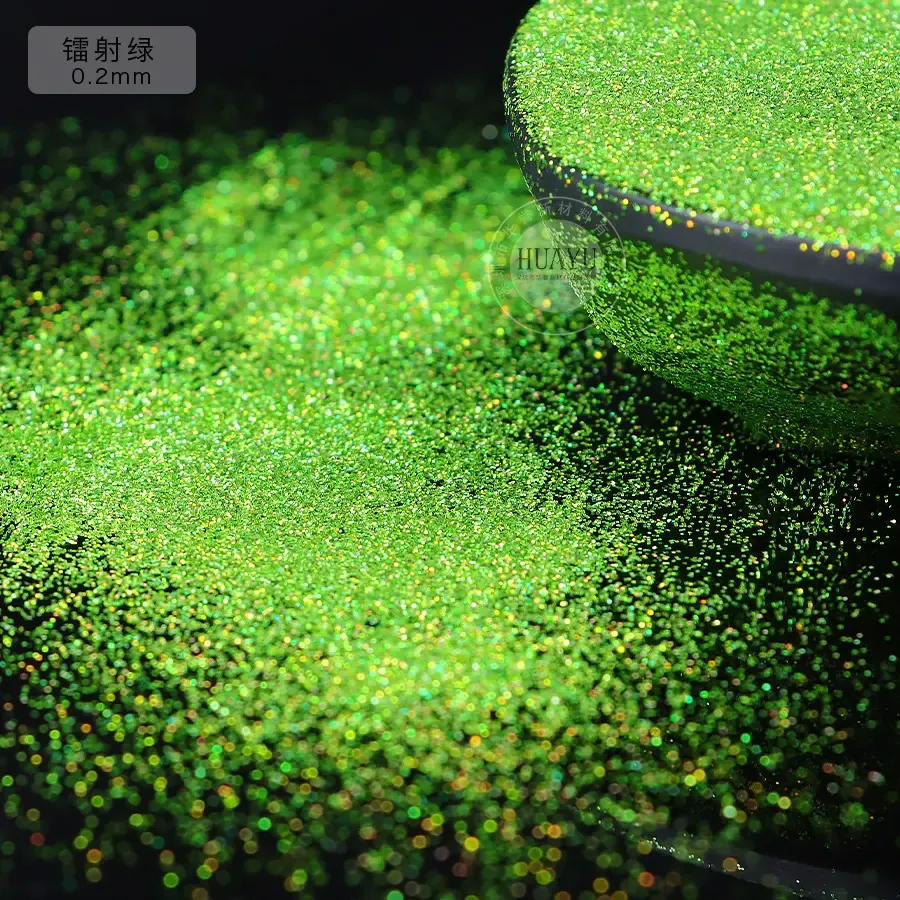

Mica powder has gained significant attention in the craft and DIY communities for its vibrant colors and versatility. Its use in soap making, in particular, showcases both its aesthetic appeal and functional benefits. From providing shimmering, eye-catching finishes to serving as a natural coloring agent, mica powder can transform ordinary soap into a luxurious product.

Demonstrating authoritativeness in this field goes beyond simple application—it involves formulating soaps that highlight the unique properties of mica. For instance, creating layered or swirled designs can be an effective way to showcase mica's metallic sheen. One common technique is the Tiger Stripe, where alternating colors are layered to create a striking visual pattern that enhances mica's reflective qualities. Safety, a critical consideration in any soap making process, demands attention. Mica powders intended for soap making should be cosmetic-grade, ensuring they are free from heavy metals and safe for skin contact. Users should always check supplier certifications and, if in doubt, request safety data sheets. Trustworthiness in product development is paramount; soap makers must ensure that their products are not only beautiful but also safe for consumer use. To build further trust with consumers and craft enthusiasts alike, transparency in sourcing and ethical considerations should also be communicated. Mica mining has faced scrutiny due to environmental and ethical concerns, so sourcing from suppliers committed to ethical practices not only enhances brand credibility but also supports sustainable and fair-trade industries. Finally, mica's potential extends beyond just visual enhancements in soap. Its inclusion in marketing narratives—highlighting natural beauty, mineral purity, and artisanal craftsmanship—can differentiate a product in a crowded market. Educating consumers on the benefits and origins of mica fosters a deeper connection to the product, making it more appealing and trustworthy. In conclusion, the use of mica powder in soap making is not just a trend; it is a sophisticated approach to crafting products that resonate with an audience looking for beauty and integrity. By understanding and implementing best practices, soap makers can elevate their products both aesthetically and ethically, capitalizing on mica's prowess to create soaps that are as enjoyable to use as they are to behold.

Demonstrating authoritativeness in this field goes beyond simple application—it involves formulating soaps that highlight the unique properties of mica. For instance, creating layered or swirled designs can be an effective way to showcase mica's metallic sheen. One common technique is the Tiger Stripe, where alternating colors are layered to create a striking visual pattern that enhances mica's reflective qualities. Safety, a critical consideration in any soap making process, demands attention. Mica powders intended for soap making should be cosmetic-grade, ensuring they are free from heavy metals and safe for skin contact. Users should always check supplier certifications and, if in doubt, request safety data sheets. Trustworthiness in product development is paramount; soap makers must ensure that their products are not only beautiful but also safe for consumer use. To build further trust with consumers and craft enthusiasts alike, transparency in sourcing and ethical considerations should also be communicated. Mica mining has faced scrutiny due to environmental and ethical concerns, so sourcing from suppliers committed to ethical practices not only enhances brand credibility but also supports sustainable and fair-trade industries. Finally, mica's potential extends beyond just visual enhancements in soap. Its inclusion in marketing narratives—highlighting natural beauty, mineral purity, and artisanal craftsmanship—can differentiate a product in a crowded market. Educating consumers on the benefits and origins of mica fosters a deeper connection to the product, making it more appealing and trustworthy. In conclusion, the use of mica powder in soap making is not just a trend; it is a sophisticated approach to crafting products that resonate with an audience looking for beauty and integrity. By understanding and implementing best practices, soap makers can elevate their products both aesthetically and ethically, capitalizing on mica's prowess to create soaps that are as enjoyable to use as they are to behold.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories