Feb . 10, 2025 18:01

Back to list

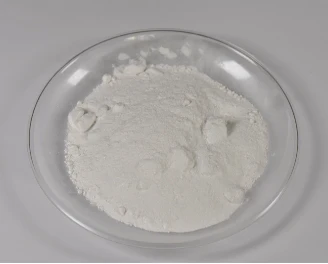

40-D Mica Powder

Using mica powder in wax melts can be a creative way to add color and shimmer to your creations, appealing to both hobbyists and professionals in the candle-making industry. However, there are a few critical considerations to ensure quality and safety, as well as to optimize the experience for both makers and end-users.

Authoritativeness is built through credible information and sourcing your materials from reputable suppliers. Quality mica powders should be non-toxic, skin safe, and ideally cosmetic grade to ensure they are safe for use in all settings. It’s also vital to consult with Material Safety Data Sheets (MSDS) for each mica variant to understand the safe handling procedures and environmental considerations. For trustworthiness, transparency about the mica used—such as its origin, safety standards, and instructions on how to achieve the best results—can provide peace of mind to consumers. User testimonials and expert endorsements can serve to reinforce the credibility of using mica in wax melts. If issues arise, such as clogging in wax warmers or inconsistent colors, providing solutions or alternatives will demonstrate a commitment to consumer satisfaction. Ultimately, using mica powder in wax melts can enhance the aesthetic appeal and sensory experience of the product. If done correctly, this craft can achieve a delightful balance of visual and olfactory allure, making your wax melts stand out in a competitive market. Whether you are an entrepreneur or a DIY enthusiast, ensuring you have a firm grasp of the materials and processes involved will lead to successful and safe wax melt creations, admired and trusted by your audience.

Authoritativeness is built through credible information and sourcing your materials from reputable suppliers. Quality mica powders should be non-toxic, skin safe, and ideally cosmetic grade to ensure they are safe for use in all settings. It’s also vital to consult with Material Safety Data Sheets (MSDS) for each mica variant to understand the safe handling procedures and environmental considerations. For trustworthiness, transparency about the mica used—such as its origin, safety standards, and instructions on how to achieve the best results—can provide peace of mind to consumers. User testimonials and expert endorsements can serve to reinforce the credibility of using mica in wax melts. If issues arise, such as clogging in wax warmers or inconsistent colors, providing solutions or alternatives will demonstrate a commitment to consumer satisfaction. Ultimately, using mica powder in wax melts can enhance the aesthetic appeal and sensory experience of the product. If done correctly, this craft can achieve a delightful balance of visual and olfactory allure, making your wax melts stand out in a competitive market. Whether you are an entrepreneur or a DIY enthusiast, ensuring you have a firm grasp of the materials and processes involved will lead to successful and safe wax melt creations, admired and trusted by your audience.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories