Jan . 14, 2025 12:14

Back to list

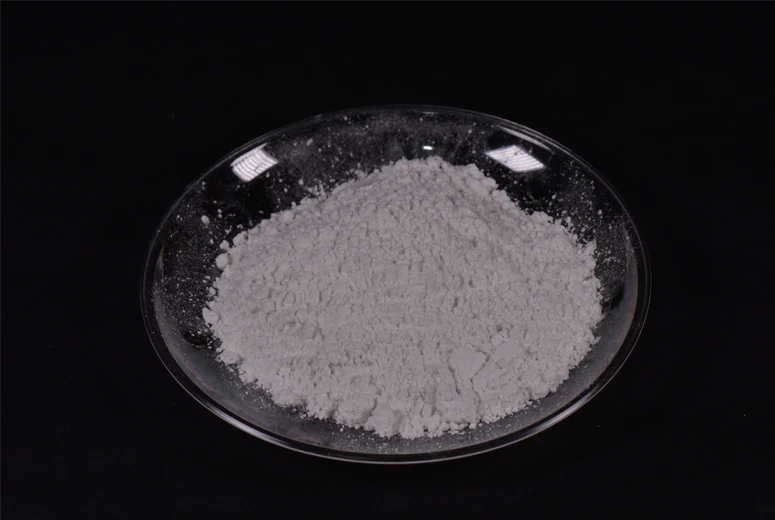

calcined mica powder

When considering the vibrant art of tie-dyeing, artists and creators are often on the lookout for novel ways to enhance their designs. A question that has surfaced recently is whether mica powder can be used effectively in the process of tie-dyeing. A common material in cosmetics and crafts, mica powder possesses a shimmering quality that adds a unique luster to art pieces, but how well does it integrate with fabric dyeing?

From a professional standpoint, understanding the composition of your mica powder is critical. Authentic mica powder, derived from naturally occurring minerals, is more reliable compared to synthetic alternatives. Analyzing the mica’s particle size and colorfastness can preemptively address potential issues during and after the dyeing process. Larger mica particles, while striking, may not penetrate fibers as finely as smaller ones, influencing both the visual and textural outcome of the fabric. Furthermore, seasoned artisans emphasize the importance of protective gear when handling mica powder. Although generally safe, extended exposure to fine powders can cause irritation, thus wearing masks and gloves during mixing and application is advisable. In conclusion, while traditional tie-dye does not typically incorporate mica powder, integrating it requires an understanding of the medium's characteristics and its interaction with fabric. By approaching mica tie-dye with a structured testing method, utilizing effective binding agents, and selecting appropriate materials, creators can achieve stunning, luminescent designs that redefine tie-dyeing art. Such innovative approaches not only broaden the spectrum of textile art but also pave the way for new creative possibilities.

From a professional standpoint, understanding the composition of your mica powder is critical. Authentic mica powder, derived from naturally occurring minerals, is more reliable compared to synthetic alternatives. Analyzing the mica’s particle size and colorfastness can preemptively address potential issues during and after the dyeing process. Larger mica particles, while striking, may not penetrate fibers as finely as smaller ones, influencing both the visual and textural outcome of the fabric. Furthermore, seasoned artisans emphasize the importance of protective gear when handling mica powder. Although generally safe, extended exposure to fine powders can cause irritation, thus wearing masks and gloves during mixing and application is advisable. In conclusion, while traditional tie-dye does not typically incorporate mica powder, integrating it requires an understanding of the medium's characteristics and its interaction with fabric. By approaching mica tie-dye with a structured testing method, utilizing effective binding agents, and selecting appropriate materials, creators can achieve stunning, luminescent designs that redefine tie-dyeing art. Such innovative approaches not only broaden the spectrum of textile art but also pave the way for new creative possibilities.

Prev:

Next:

Latest news

-

Transforming Surfaces with Mica-Enhanced Paints in Coatings and DecorationNewsJul.02,2025

-

The Ultimate Guide to Mica-Based Luminous Colors with Pearlescent PigmentNewsJul.02,2025

-

The Critical Role of Mica in Industrial Applications in Welding and Oil FieldsNewsJul.02,2025

-

Revolutionizing Automotive Aesthetics with Modified Plastics Pearlescent PigmentsNewsJul.02,2025

-

The Secret with Mica Powder for Cosmetics Behind Radiant, Natural MakeupNewsJul.02,2025

-

Enhancing Performance in Polymer Applications with Mica Powder for RubberNewsJul.02,2025

Products categories